Propylene epoxide purifying method and purifying device

A technology of propylene oxide and purification methods, applied in organic chemistry, azeotropic distillation, etc., to achieve the effects of reduced energy consumption, increased yield, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

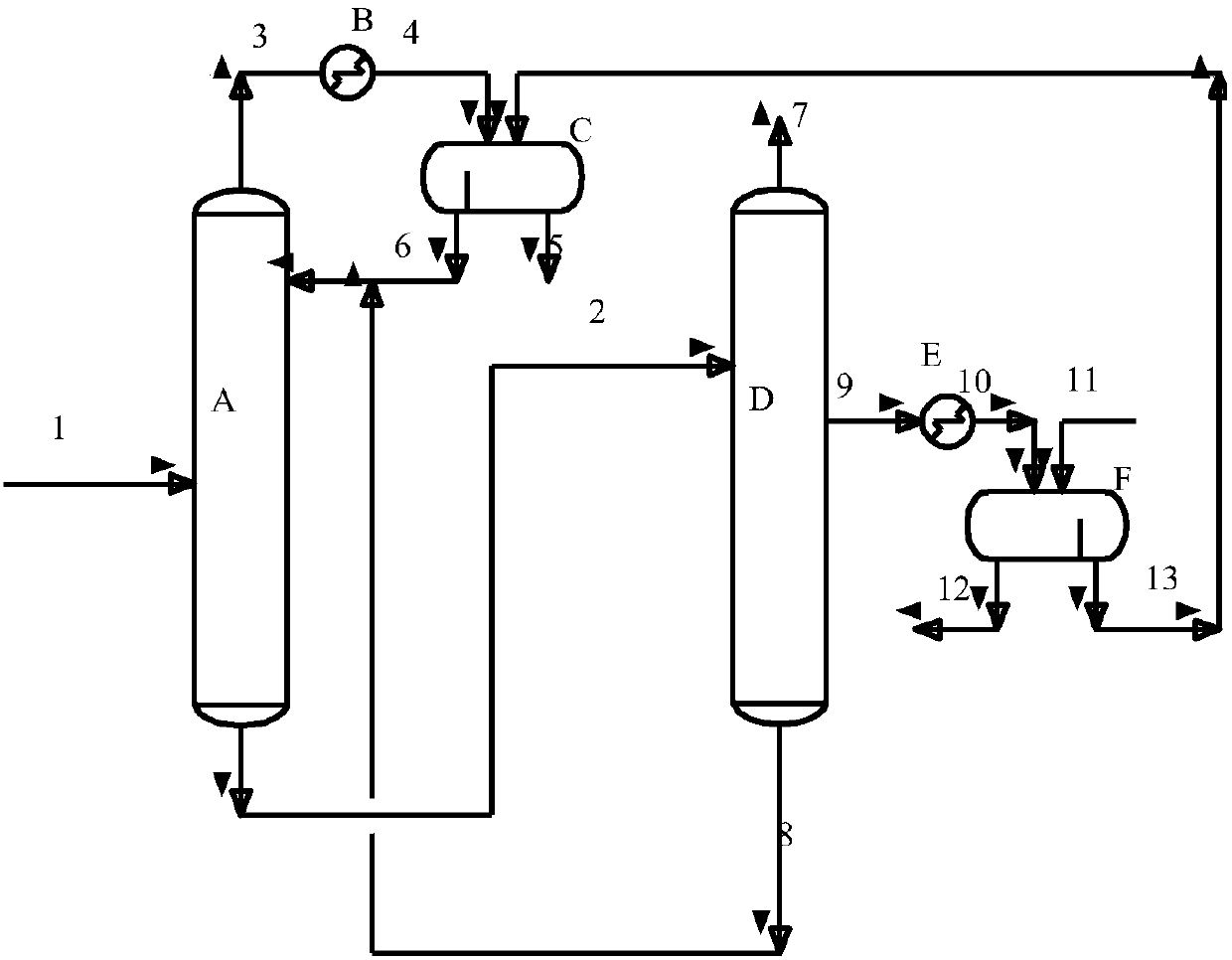

[0096] according to figure 1 The process flow shown, the extractant is n-octane, in the stream containing 1,2-propylene oxide, extractant and impurity propylene glycol monomethyl ether, propylene glycol dimethyl ether, by weight percentage, the impurity propylene glycol monomethyl ether, propylene glycol The content of dimethyl ether is 1.0%, the ratio of extractant to 1,2-propylene oxide is 2.1:1, the number of theoretical plates of the separation tower is 30, and the side stream of the separation tower is located at the seventh theoretical plate.

[0097] Extraction tower operating conditions: pressure 0.043MPaG, tower top temperature 75°C.

[0098] The flow rate of the side stream azeotrope is 1.5:1 of the impurity flow rate contained in the feed stream; the pressure of the side stream is 0.02MPaG, the temperature is 100°C, the impurity propylene glycol monomethyl ether and propylene glycol dimethyl ether content is 52.85wt%, and the side stream impurity propylene glycol M...

Embodiment 2

[0101] according to figure 1 The process flow shown, the extractant is n-octane, in the stream containing 1,2-propylene oxide, extractant and impurity propylene glycol monomethyl ether, propylene glycol dimethyl ether, by weight percentage, the impurity propylene glycol monomethyl ether, propylene glycol The content of dimethyl ether is 1.0%, the ratio of extractant to 1,2-propylene oxide is 2.1:1, the number of theoretical plates of the separation tower is 30, and the side stream of the separation tower is located at the seventh theoretical plate.

[0102] Extraction tower operating conditions: pressure 0.043MPaG, tower top temperature 75°C.

[0103] The flow rate of the side stream azeotrope is 2.5:1 of the impurity flow rate contained in the feed stream; the pressure of the side stream is 0.02MPaG, the temperature is 100°C, the content of impurity propylene glycol monomethyl ether and propylene glycol dimethyl ether is 52.85wt%, and the side stream impurity propylene glycol...

Embodiment 3

[0106] according to figure 1 The process flow shown, the extractant is n-octane, in the stream containing 1,2-propylene oxide, extractant and impurity propylene glycol monomethyl ether, propylene glycol dimethyl ether, by weight percentage, the impurity propylene glycol monomethyl ether, propylene glycol The content of dimethyl ether is 1.0%, the ratio of extractant to 1,2-propylene oxide is 2.1:1, the number of theoretical plates of the separation tower is 30, and the side stream of the separation tower is located at the seventh theoretical plate.

[0107] Extraction tower operating conditions: pressure 0.043MPaG, tower top temperature 75°C.

[0108] The flow rate of the azeotrope stream produced by the side stream is 3.5:1 of the impurity flow rate contained in the feed stream; the pressure of the side stream is 0.02MPaG, the temperature is 100°C, the content of impurity propylene glycol monomethyl ether and propylene glycol dimethyl ether is 52.85wt%, and the side stream im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com