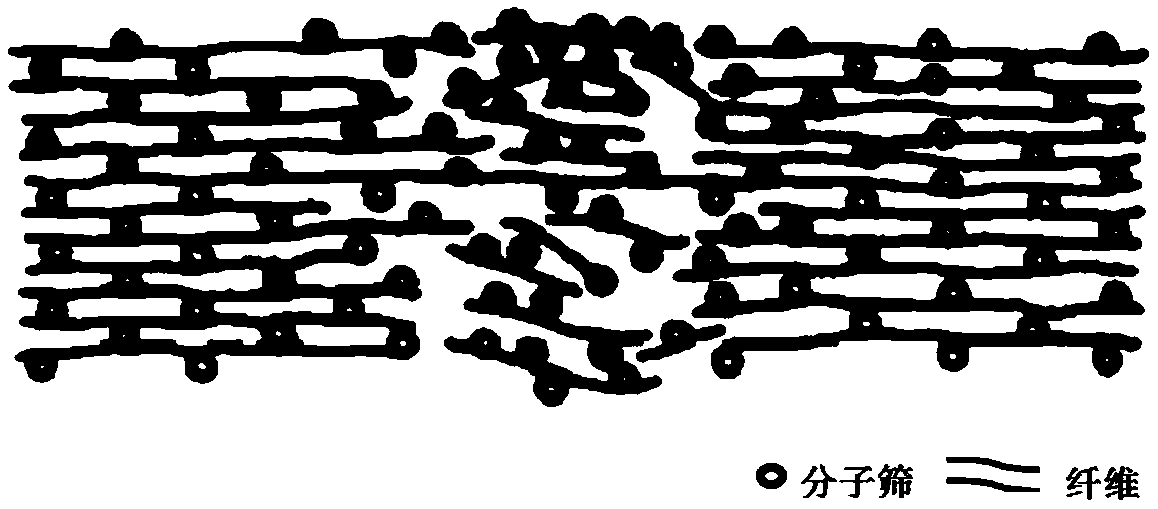

Molecular sieve/fiber composite material and preparation method therefor

A fiber composite material and molecular sieve technology, applied in the field of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

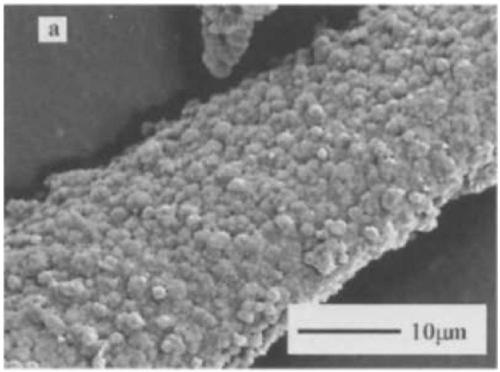

[0176] The preparation method of Y-type molecular sieve / cotton fiber composite material of the present invention may further comprise the steps:

[0177] ① Prepare the molecular sieve precursor solution, according to the following molar ratio 10Na 2 O: Al 2 o 3 :9SiO2 2 :200H 2 O constitutes the starting material to synthesize the molecular sieve precursor solution. The molecular sieve precursor solution is mixed with cotton fiber, and the mass ratio of cotton fiber to molecular sieve precursor solution is 1:20.

[0178] ②The cotton fiber and the homogeneously mixed molecular sieve precursor solution were transferred and heat-treated at 100°C for 24 hours to obtain a Y-type molecular sieve / cotton fiber composite material.

[0179] Randomly take 10 samples of the prepared Y-type molecular sieve / cotton fiber composite material at different positions, and analyze the content of the Y-type molecular sieve on the fiber surface by a thermogravimetric analyzer. The contents of t...

Embodiment 2

[0246] The preparation method of chabazite / cotton fiber composite material of the present invention, comprises the following steps:

[0247] ① Prepare the molecular sieve precursor solution, according to the following molar ratio 10Na 2 O: Al 2 o 3 :9SiO2 2 :300H 2 O constitutes the starting material to synthesize the molecular sieve precursor solution. The molecular sieve precursor solution is mixed with cotton fiber, and the mass ratio of cotton fiber to molecular sieve precursor solution is 1:0.5.

[0248] ②The cotton fiber and the uniformly mixed molecular sieve precursor solution were heat-treated at 80°C for 36 hours to obtain the chabazite / cotton fiber composite material.

[0249] Randomly get 10 samples of the prepared chabazite / cotton fiber composite material in different positions, analyze the content of chabazite on the fiber surface, the average content of molecular sieve on the fiber can be 25wt% in the 10 samples, and the sample standard deviation is 2.5wt%...

Embodiment 3

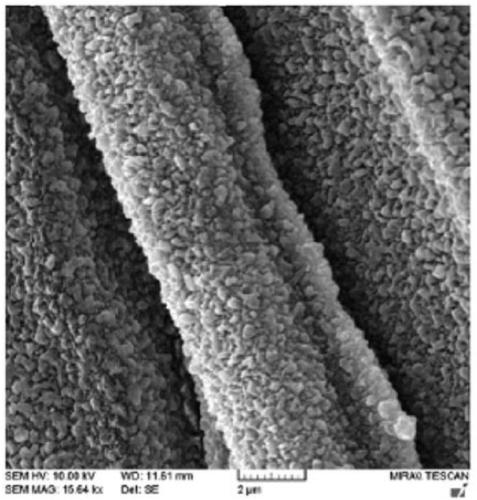

[0251] The preparation method of X-type molecular sieve / silk fiber composite material of the present invention comprises the following steps:

[0252] ① Prepare the molecular sieve precursor solution according to the following molar ratio 5.5Na 2 O:1.65K 2 O: Al 2 o 3 :2.2SiO2 2 :122H 2 O constitutes the starting material to synthesize the molecular sieve precursor solution. The molecular sieve precursor solution is mixed with the silk fiber, and the mass ratio of the silk fiber to the molecular sieve precursor solution is 1:10.

[0253] ②The silk fiber and the uniformly mixed molecular sieve precursor solution were heat-treated at 100°C for 12 hours to obtain the X-type molecular sieve / silk fiber composite material.

[0254] The obtained X-type molecular sieve / silk fiber composite material is randomly taken 8 samples in different positions, and the content of the X-type molecular sieve on the fiber surface is analyzed, and the average content of the molecular sieve on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com