A kind of duplex stainless steel and preparation method thereof

A duplex stainless steel and steel billet technology, applied in the field of duplex stainless steel, can solve the problems of corrosion resistance and thermoforming performance, difficulty in ensuring the stability of the two-phase structure, and increasing the difficulty of thermal processing, so as to improve thermal processing performance, Increase the content of nitrogen and the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

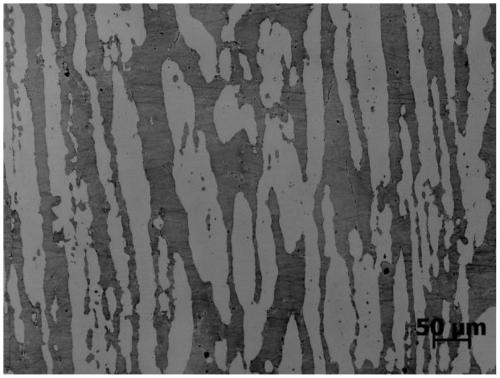

[0050] The duplex stainless steel of this embodiment is composed of the following elements by weight: C: 0.01%, Cr: 26%, Ni: 0.8%, Mo: 4.9%, Mn: 0.5%, N: 0.6%, Ce: 0.18% , Co: 0.2%, Si: 0.5%, P: 0.02%, S: 0.02%, and the balance is Fe and unavoidable impurity elements, wherein the weight percentage of impurity elements is 0.008%.

[0051] In this example, the ratio of Cr equivalent to Ni equivalent is 1.64, where Cr eq =Cr wt.%+Mo wt.%+1.5×Si wt.%+0.5×Nb wt.%=26%+4.9%+1.5×0.5%+0.5×0=31.65%; Ni eq =Ni wt.%+30×(C wt.%+N wt.%)+0.5×Mn wt.%=0.8%+30×(0.01%+0.6%)+0.5×0.5%=19.35%. The PREN value of the duplex stainless steel in this example is 51.77, and the PREN value is Cr%+3.3×Mo%+16×N%=26%+3.3×4.9%+16×0.6%=51.77%.

Embodiment 2

[0053] The duplex stainless steel of this embodiment is composed of the following elements by weight: C: 0.01%, Cr: 27%, Ni: 0.8%, Mo: 5%, Mn: 0.5%, N: 0.6%, Ce: 0.18% , Co: 0.3%, Si: 0.5%, P: 0.02%, S: 0.02%, and the balance is Fe and unavoidable impurity elements, wherein the weight percentage of impurity elements is 0.08%.

[0054] In this example, the ratio of Cr equivalent to Ni equivalent is 1.69, where Cr eq =Cr wt.%+Mo wt.%+1.5×Si wt.%+0.5×Nb wt.%=27%+5%+1.5×0.5%+0.5×0=32.75%; Ni eq=Ni wt.%+30×(C wt.%+N wt.%)+0.5×Mn wt.%=0.8%+30×(0.01%+0.6%)+0.5×0.5%=19.35%. The PREN value of the duplex stainless steel in this example is 53.1, and the PREN value=Cr%+3.3×Mo%+16×N%=27%+3.3×5%+16×0.6%=53.1%.

Embodiment 3

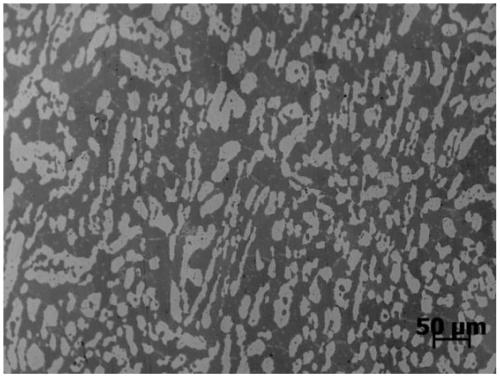

[0056] The duplex stainless steel of this embodiment is composed of the following elements by weight: C: 0.01%, Cr: 27%, Ni: 1.5%, Mo: 5.6%, Mn: 0.6%, N: 0.63%, Ce: 0.18% , Co: 0.4%, Si: 0.6%, P: 0.02%, S: 0.02%, and the balance is Fe and unavoidable impurity elements, wherein the weight percentage of impurity elements is 0.08%.

[0057] In this example, the ratio of Cr equivalent to Ni equivalent is 1.6, where Cr eq =Cr wt.%+Mo wt.%+1.5×Si wt.%+0.5×Nb wt.%=27%+1.5×0.6%+0.5×0=33.5%; Ni eq =Ni wt.%+30×(Cwt.%+N wt.%)+0.5×Mn wt.%=1.5%+30×(0.01%+0.63%)+0.5×0.6%=21. The PREN value of the duplex stainless steel in this example is 55.56, and the PREN value=Cr%+3.3×Mo%+16×N%=27%+3.3×5.6%+16×0.63%=55.56%.

[0058] Example 1 of the preparation method of duplex stainless steel

[0059] The elements and weight percentages in the stainless steel prepared in the preparation method of the duplex stainless steel in this embodiment are the same as in Example 1 of the duplex stainless steel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com