Drum-washing-machine front-cover assembly and preparing method thereof

A drum washing machine and front cover assembly technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve problems such as scratch resistance, discoloration, and strong sense of staleness, and achieve tight and reliable integration, improve user experience, and take into account safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

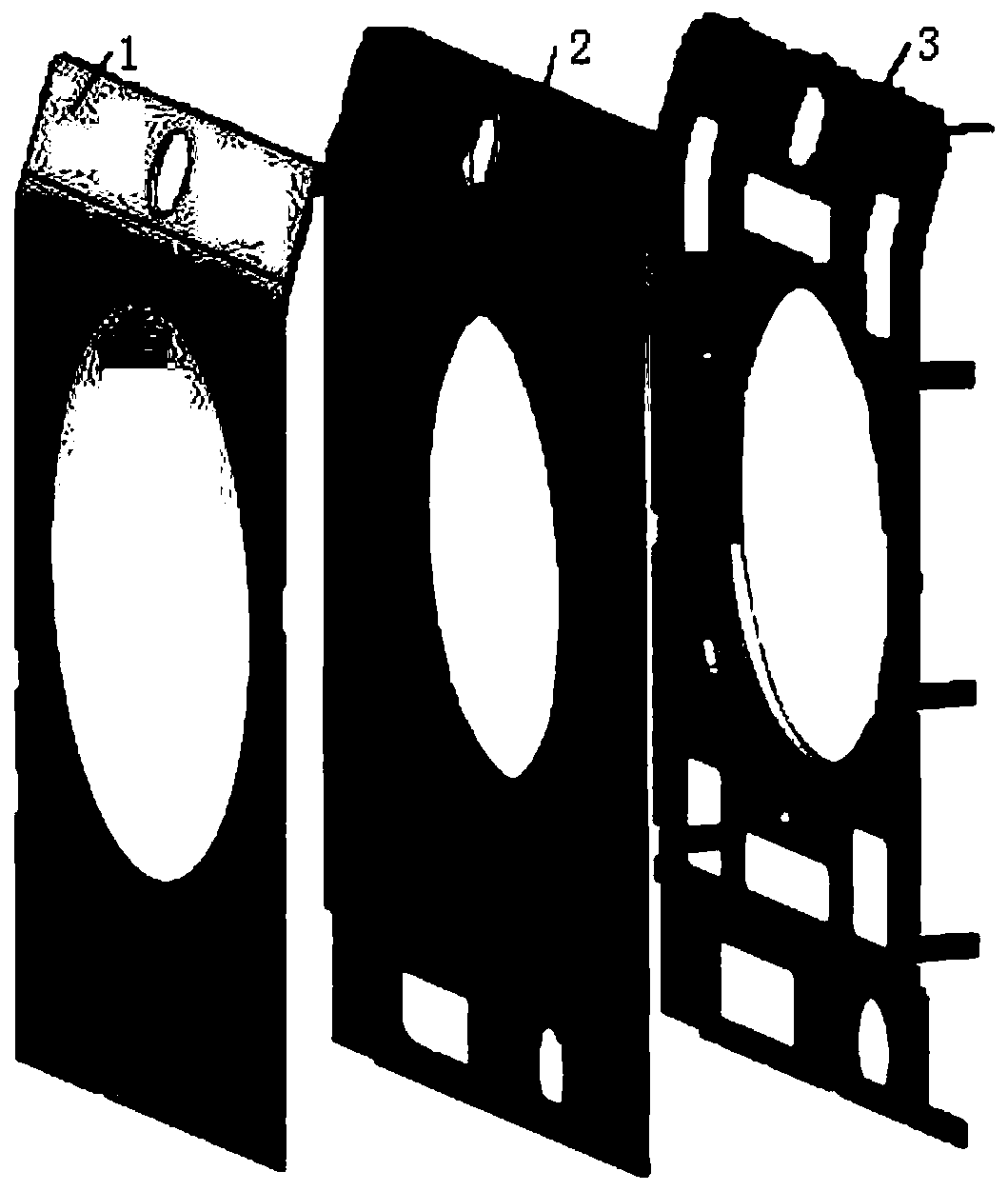

[0024] refer to figure 1 , the front cover assembly of the drum washing machine proposed by the present invention includes a front panel and a steel frame, an intermediate layer is arranged between the front panel and the steel frame, and the front panel is bonded to the steel frame through an injection-molded intermediate layer. On the framework, the steel framework is provided with a slot and a buckle component, and the slot and buckle assembly provided on the steel framework is used to be installed on a washing machine.

[0025] The material of the middle layer is PVC, and the material of the middle layer is PVC, which can closely combine the front panel and the steel frame, and can take into account safety, durability and weather resistance while retaining the good appearance and touch of the front panel .

[0026] The front panel is made of toughened glass or transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com