A micro-semiconductor nozzle structure

A semiconductor and miniature technology, which is applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve the problems of short service life of micro-semiconductor electric nozzles, scrapping of micro-semiconductor electric nozzles, and high discharge voltage under air pressure, so as to avoid product scrapping , Improve the appearance of welding and the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

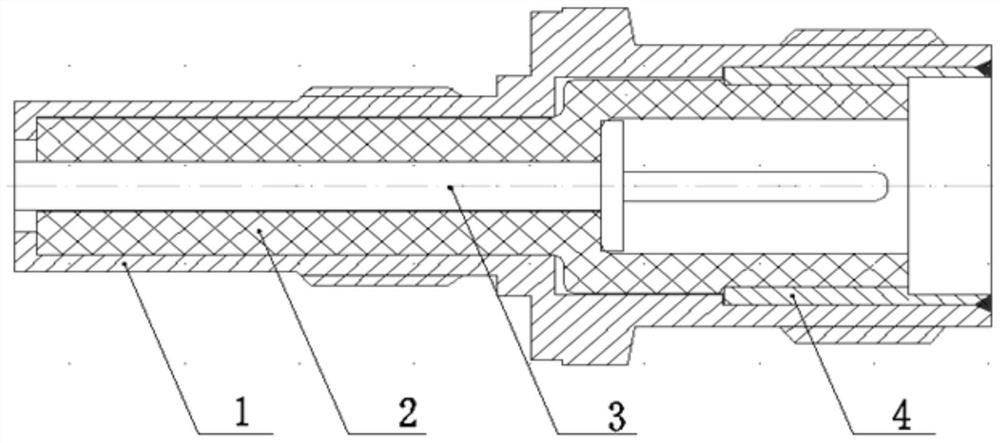

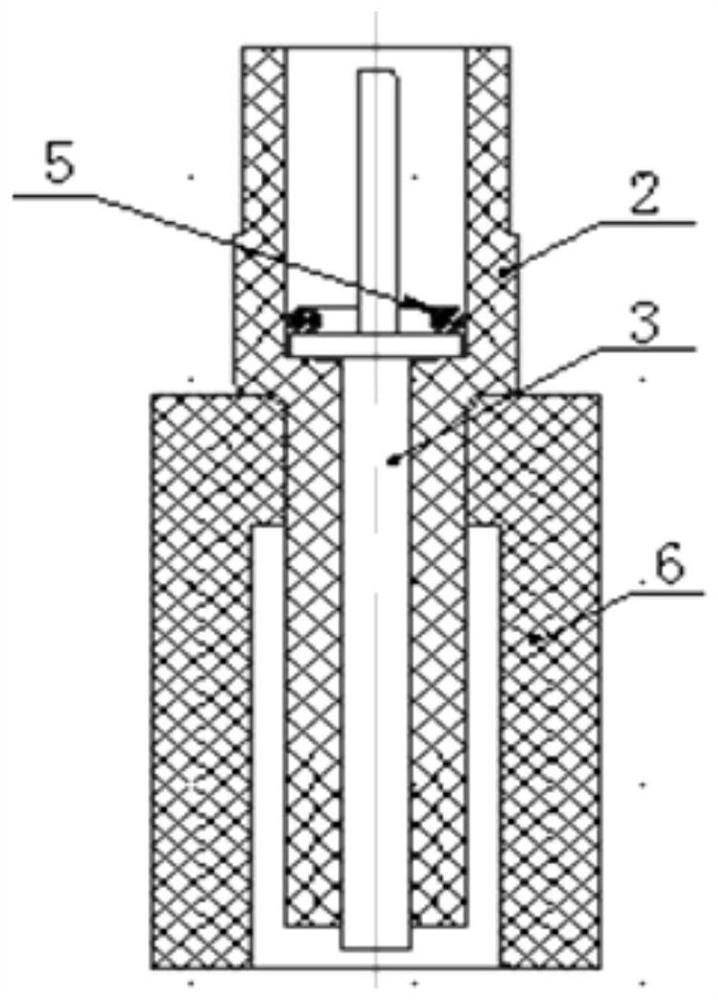

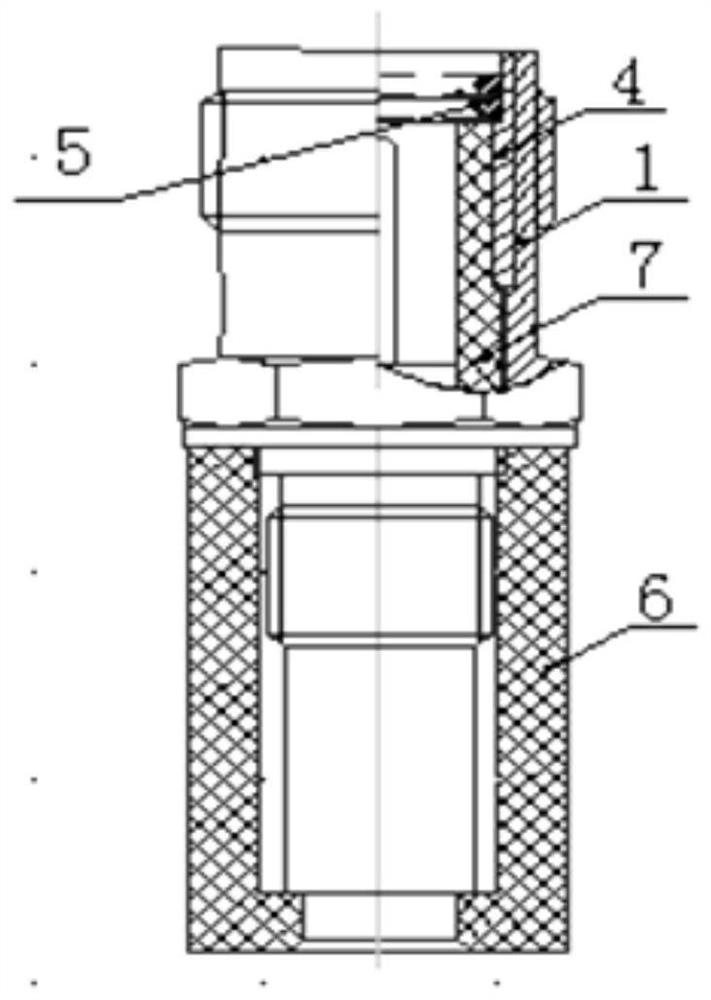

[0044] A kind of micro-semiconductor nozzle structure of the present invention, is by the parts such as housing 1, insulator 2, the center electrode 3 of discharge end band cap, sealing and fixed center electrode 3 and disc 8 of insulator 2 by means of certain tooling ( 6-1, 6-2, 6-3) are brazed in a hydrogen furnace, such as Figure 4 and Figure 5 as shown, Figure 4 Structural diagram of the miniature semiconductor electric nozzle proposed for the present invention; Figure 5 It is the brazing assembly diagram of the miniature semiconductor electric nozzle proposed by the present invention.

[0045] The electric nozzle produced by the micro-semiconductor electric nozzle structure provided by the present invention has good comprehensive performance, low d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com