Electromagnetic reciprocating compressor

A compressor and reciprocating technology, applied in the field of compressors, can solve the problems of affecting the service life of the motor, poor system operation stability, high cost investment, etc., and achieve the effects of small space occupation, stable and reliable operation, and low starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

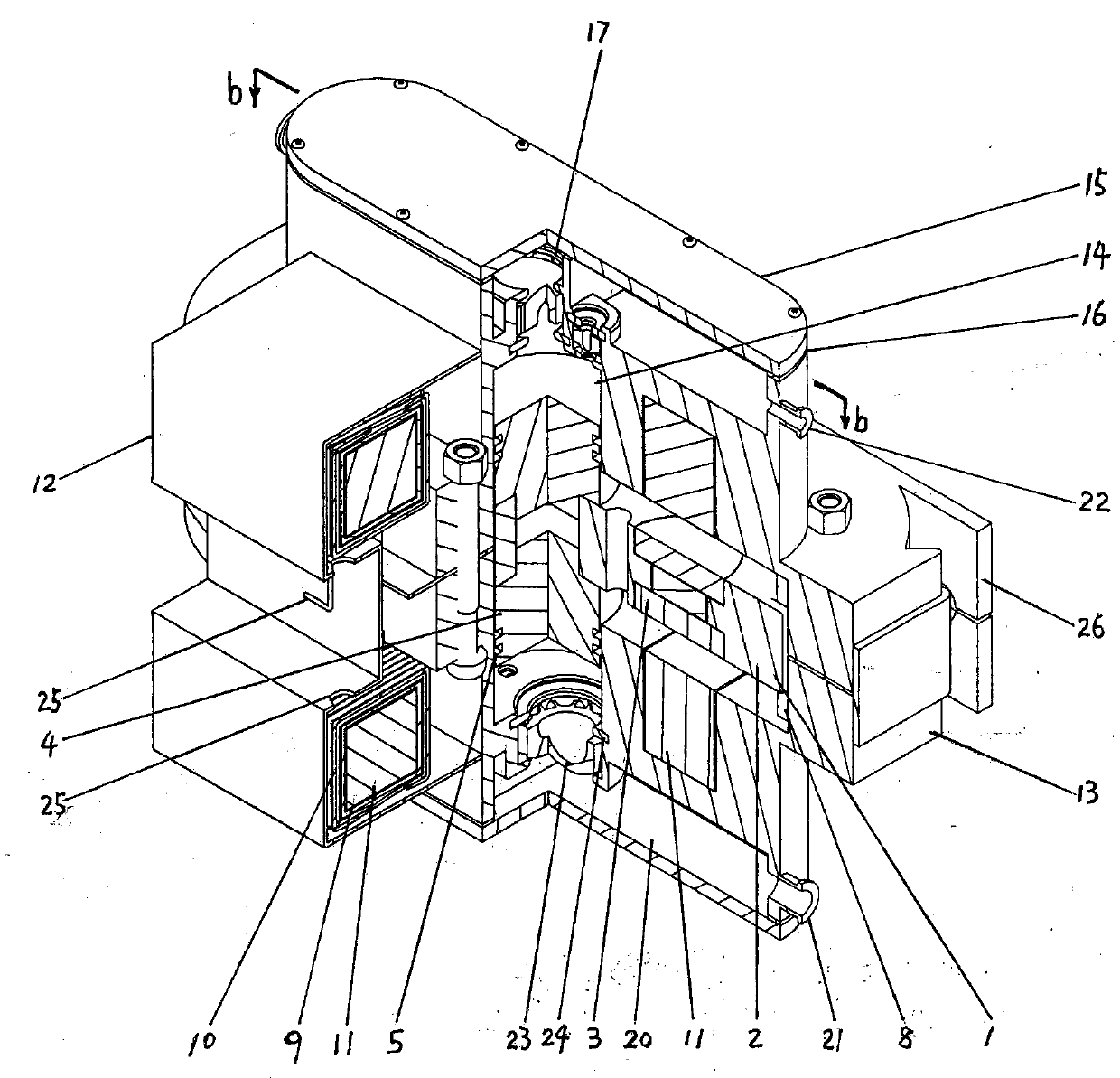

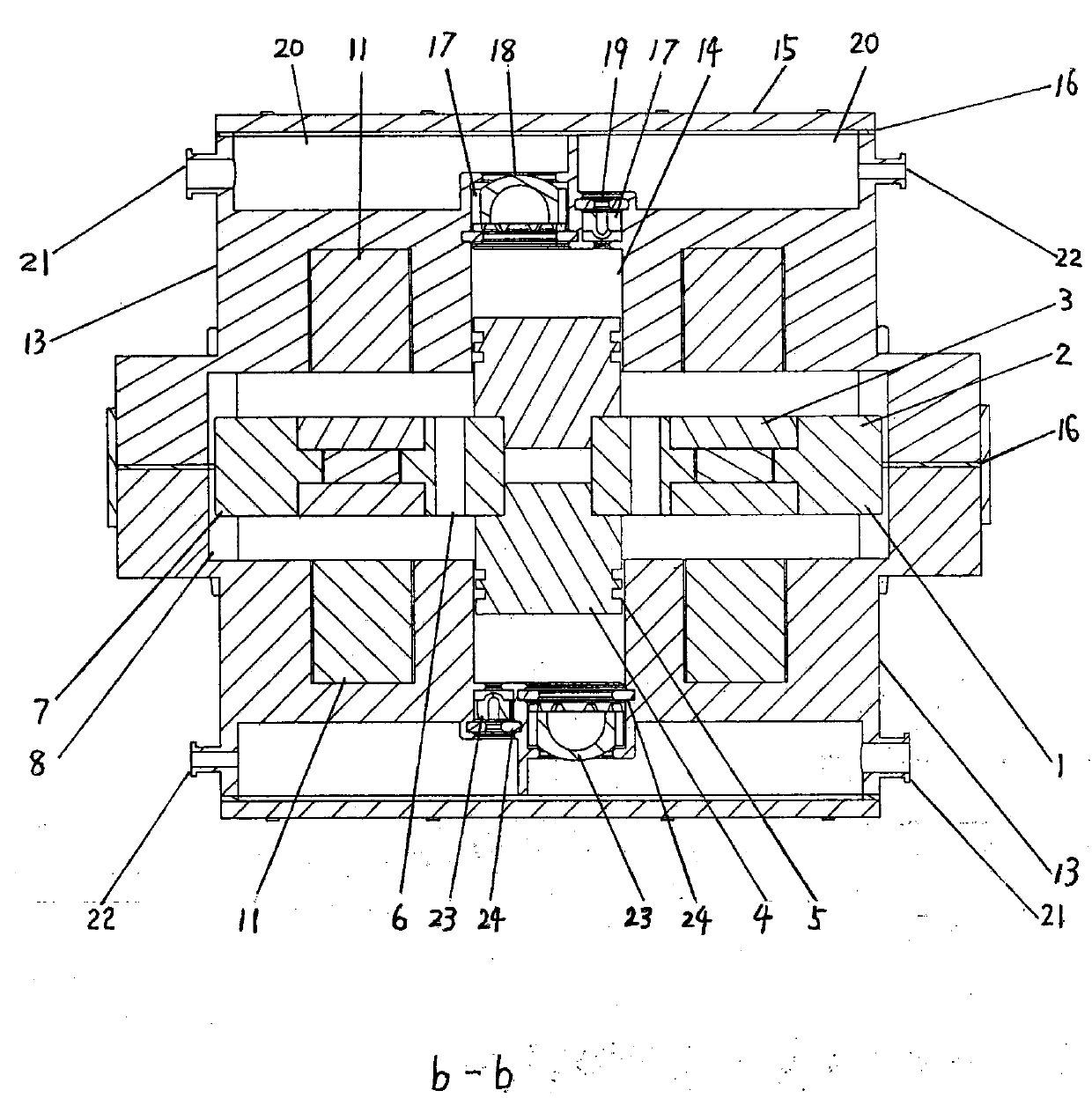

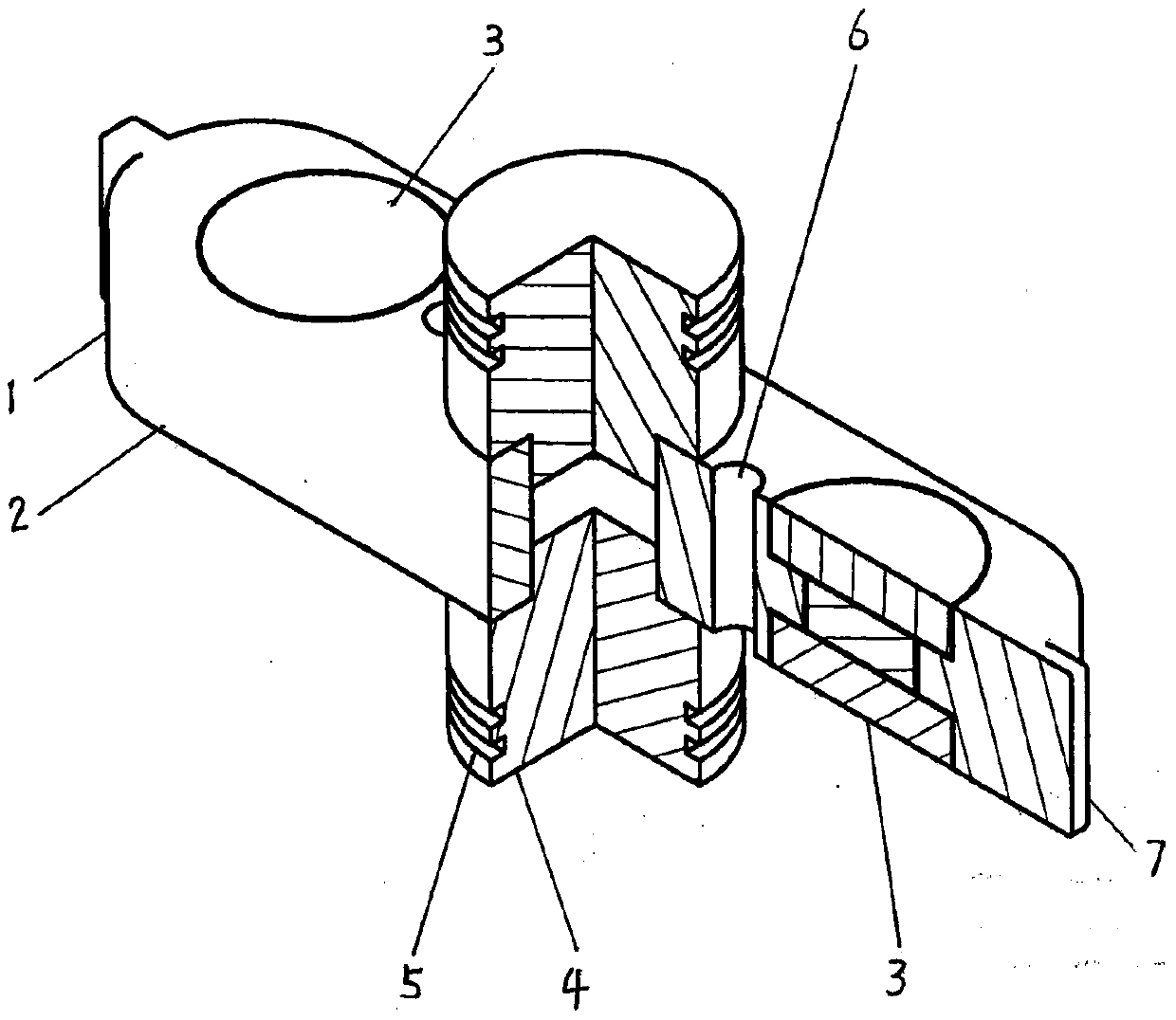

[0018] In the embodiment of the present invention, refer to figure 1As shown in the drawings, the electromagnetic reciprocating compressor, the piston permanent magnet combination slider 1, includes a non-magnetic metal base frame 2, which is usually made of non-magnetic material aluminum alloy or copper alloy, and the base frame 2 is installed on both sides A permanent magnet block 3, or a plurality of permanent magnet blocks 3 are installed on the base frame 2. The permanent magnet is made of rare earth NdFeB strong magnetic material. The permanent magnet block 3 is usually composed of two or three magnets connected in series. The permanent magnets on both sides The position of the block 3 corresponds to the position of the silicon steel electromagnetic core 11 on both sides. The magnetic polarity of the permanent magnet blocks 3 on both sides is opposite. There are piston rings 5, and there are chute tongues 7 at both ends of the base frame 2. The chute tongues 7 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com