Supporting plates and supporting device for supporting arch heat exchange tube in heat exchanger as well as mounting method of supporting device

A technology of support device and installation method, which is applied in the direction of heat exchanger shell, assembly machine, heat exchange equipment, etc., can solve the problems of poor tube bundle support rigidity, poor support rigidity, collapse, etc., and achieves strong support structure rigidity and support rigidity. Strong, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

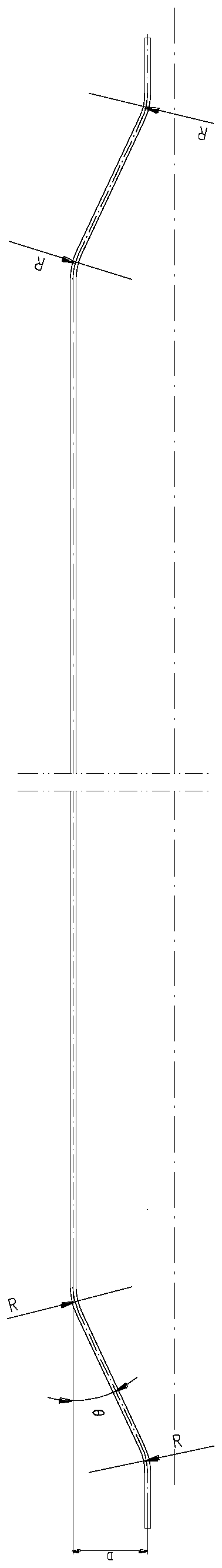

[0041] Such as Figure 7 As shown, this embodiment provides a support plate for supporting arcuate heat exchange tubes in a heat exchanger, the first side 101 of the support plate 10 is provided with a concave first clamping hole 102, and the second side 103 is provided with a concave second clamping hole 104; wherein, the first side 101 and the second side 103 are parallel to each other and are respectively located on opposite sides of the support plate 10, the first clamping hole 102 and the second clamping hole 104 are respectively It is used to fix the top and bottom of the two layers of arcuate heat exchange tubes adjacent up and down in the height direction; and there is also a gap between the first side 101 and the second side 103 of the support plate 10 for the catalyst to pass through. Leak 105.

[0042] The specifications of the first clamping hole 102 and the second clamping hole 104 are consistent, and both are semicircular holes.

[0043] During processing, in o...

Embodiment 2

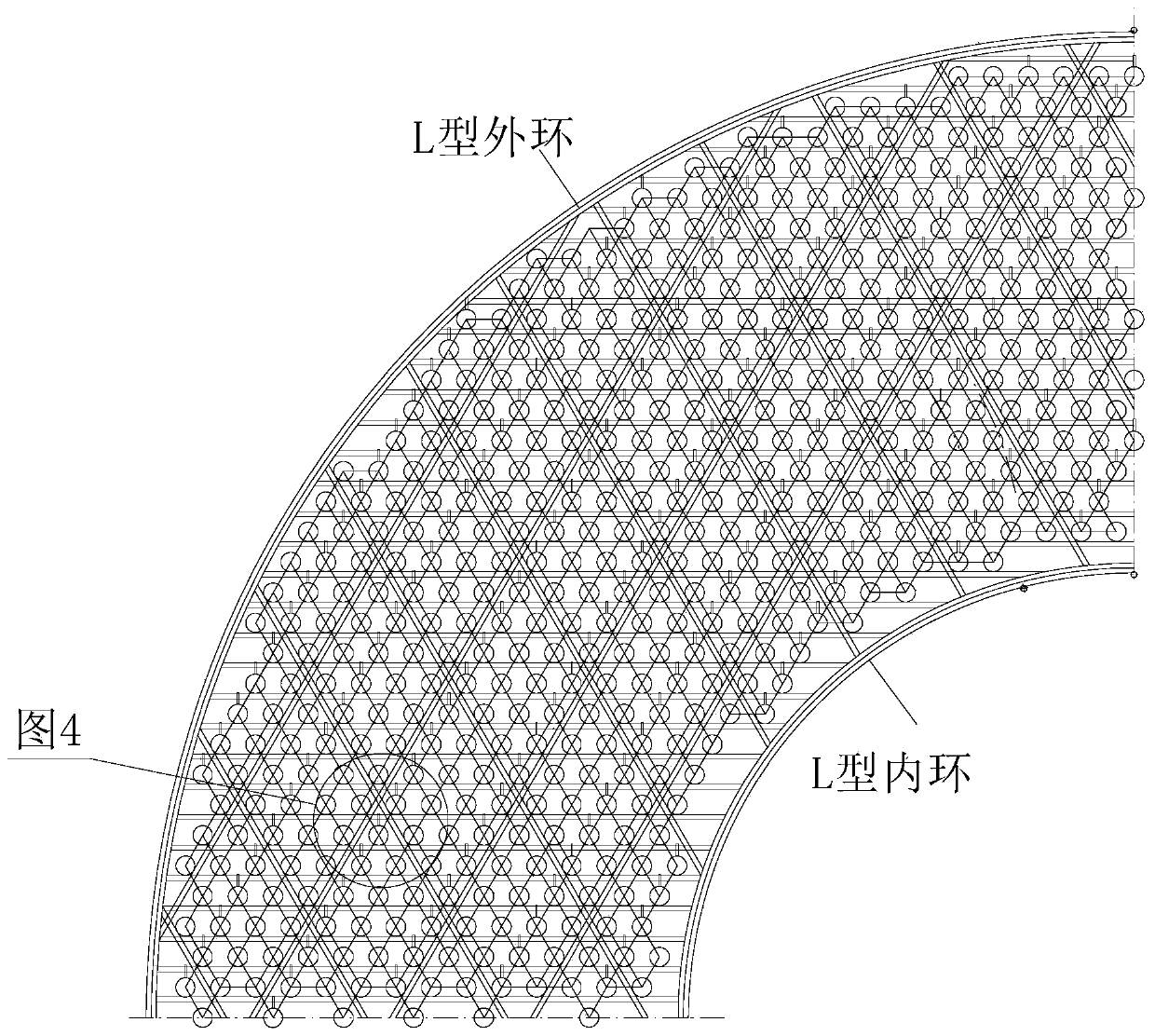

[0048] This embodiment provides a support device for supporting arcuate heat exchange tubes in a heat exchanger. The support device is composed of several support plates 10 described in Embodiment 1. The length L of each support plate 10 depends on its supporting Depending on the position in the device, each support plate 10 is welded to each other to form an annular support device. The outer side of each support plate 10 is fixed to the L-shaped outer ring 201 of the heat exchanger, and the inner side is fixed to the L-shaped inner ring 202 of the heat exchanger. fixed.

[0049] Figure 8 It is a schematic structural view of 1 / 4 part of the supporting device in this embodiment, which is composed of Figure 8 It can be seen that the outer side of the support plate 10 is fixed to the L-shaped outer ring 201 of the heat exchanger, and the inner side is fixed to the L-shaped inner ring 202 of the heat exchanger.

[0050] Figure 9 for Figure 8 A partial enlarged view of Fi...

Embodiment 3

[0052] This embodiment provides a method for installing the support device described in Embodiment 2, which includes the following steps:

[0053] S1. According to the position of each support plate 10 in the support device, number each support plate 10 sequentially according to the order of assembly from bottom to top; Figure 10 As shown, according to the position of the support plate 10, according to the order of assembly from bottom to top, the support plate 10 is numbered from 1, Figure 10 The middle is a schematic diagram of the lower left side 1 / 4 of the support device, the support plates 10 are numbered from 1 to 33, and each label represents a support plate 10;

[0054] S2. Assemble each support plate 10 layer by layer from bottom to top according to the sequence of numbers; during the assembly process, after each support plate 10 is assembled, the corresponding bow-shaped heat exchange tubes are assembled behind the second clamping hole 104 of the support plate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com