Metal source residual amount detection device and method and evaporation equipment

A detection device and residual quantity technology, applied in measuring devices, mechanical equipment, lubrication indicator devices, etc., can solve problems such as inability to obtain accurate residual quantity, inability to accurately guide production and debugging, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

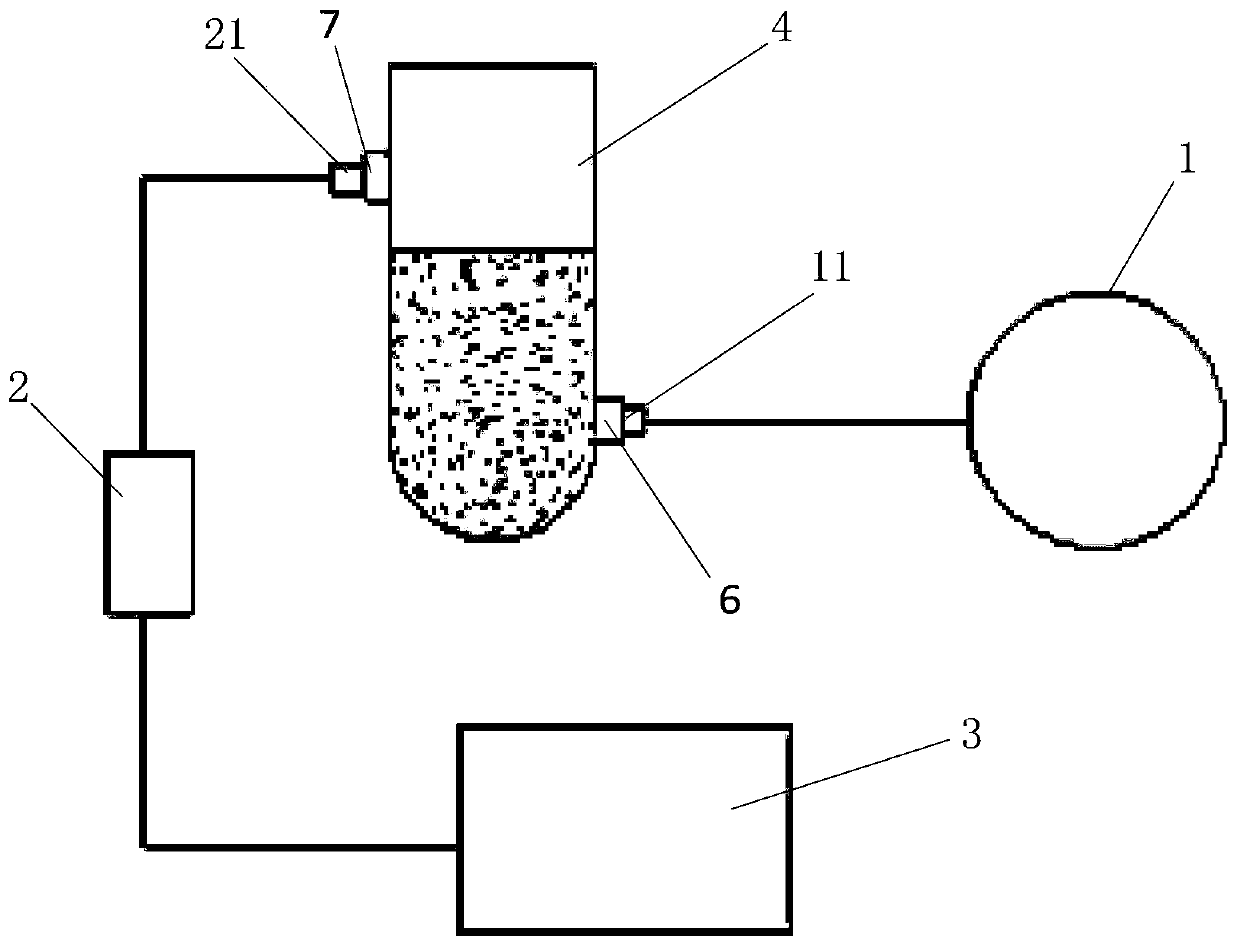

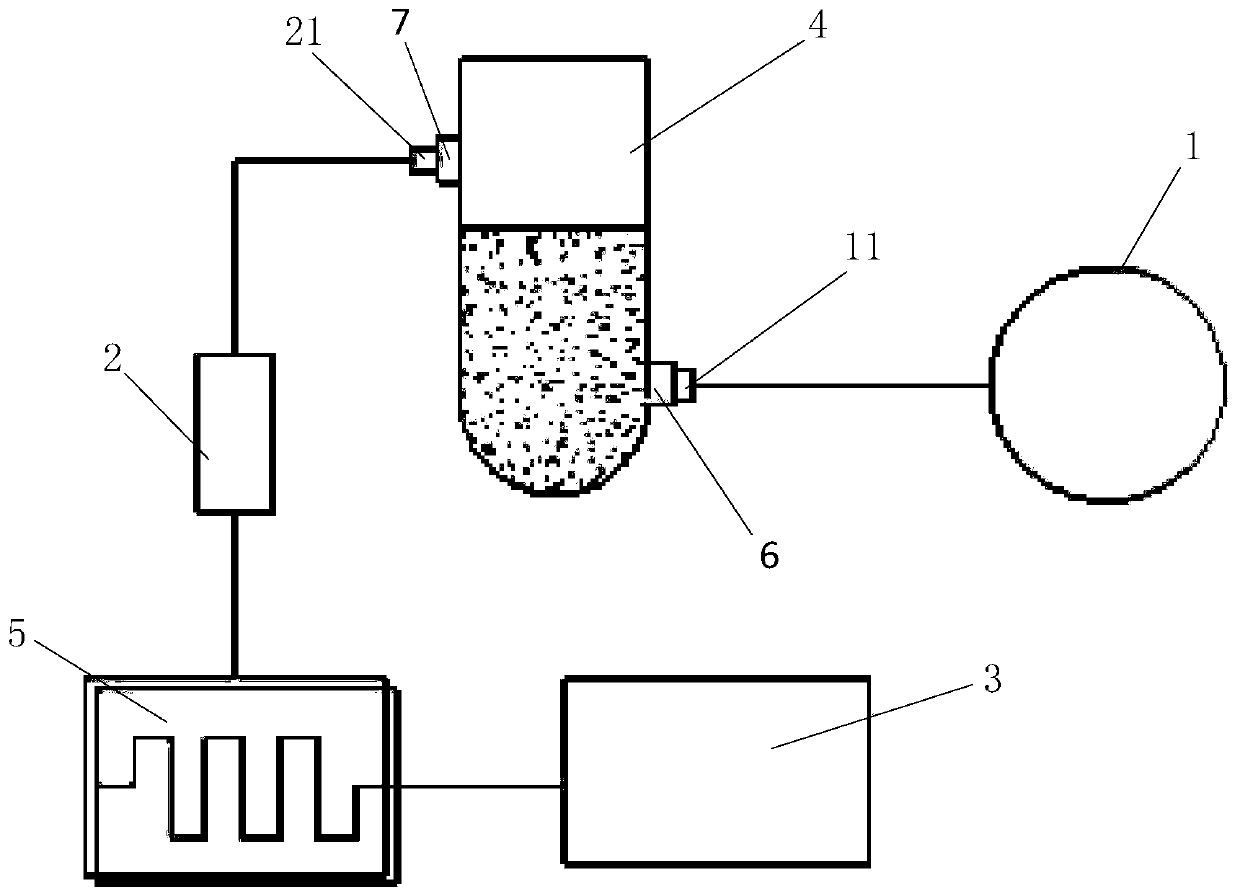

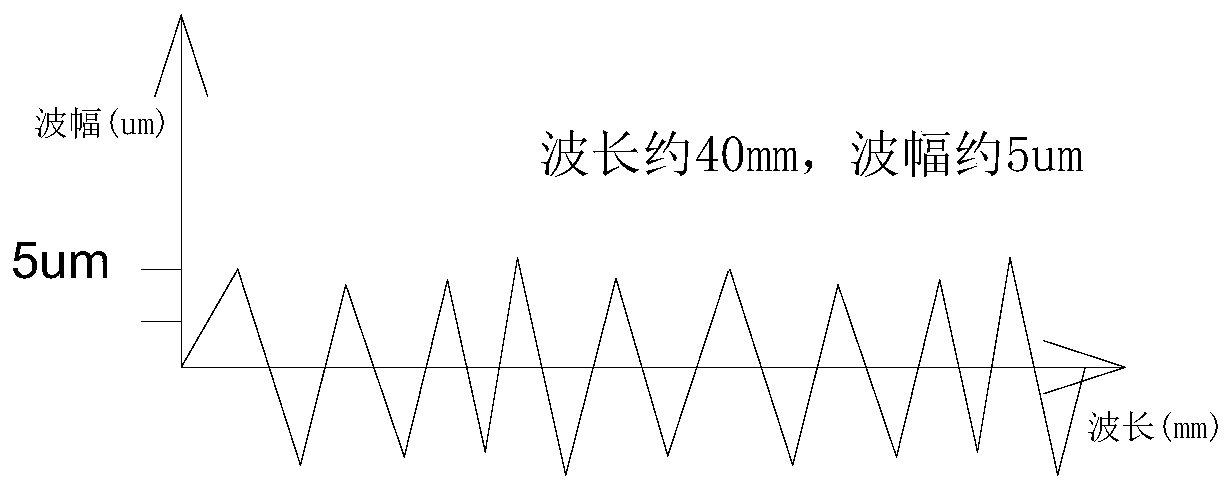

[0046] Such as figure 1 As shown, a detection device for the remaining amount of a metal source proposed in Embodiment 1 of the present invention includes: an ultrasonic generator 1, an acoustic wave receiver 2 and a controller 3, and the ultrasonic generator 1 is arranged on the outer wall of the evaporation crucible 4 The lower side or the bottom of the evaporation crucible 4, the ultrasonic generator 1 is used to generate ultrasonic waves; the acoustic wave receiving end 21 of the acoustic wave receiver 2 is arranged on the outer wall upper side of the evaporation crucible 4, and the acoustic wave receiver 2 is used to receive ultrasonic waves. The ultrasonic wave generated by the device 1; the controller 3 is used to determine the current evaporation crucible 4 according to the waveform of the ultrasonic wave received by the acoustic wave receiver 2, and the preset corresponding relationship between the remaining amount of the metal source in the evaporation crucible 4 and ...

Embodiment 2

[0062] Such as Figure 9 As shown, a method for detecting the remaining amount of a metal source proposed in Embodiment 2 of the present invention is used for the detection device for the remaining amount of a metal source provided in Embodiment 1, which includes:

[0063] 201. Receive the waveform of the ultrasonic waves received by the sound wave receiver.

[0064] Specifically, according to the device provided in Embodiment 1, the part that emits ultrasonic waves is an ultrasonic generator arranged on the lower side of the outer wall of the evaporation crucible or the bottom of the evaporation crucible, and the part that receives ultrasonic waves is arranged on the upper side of the outer wall of the evaporation crucible. acoustic receiver.

[0065] 202. According to the waveform of the ultrasonic wave and the preset corresponding relationship between the remaining amount of the metal source in the evaporation crucible and the ultrasonic waveform, determine the remaining a...

Embodiment 3

[0072] A kind of vapor deposition equipment that embodiment three of the present invention proposes, it comprises: such as figure 1 The detection device for the remaining amount of the metal source shown; the detection device for the remaining amount of the metal source includes: an ultrasonic generator 1, an acoustic wave receiver 2 and a controller 3, and the ultrasonic generator 1 is arranged on the lower side of the outer wall of the evaporation crucible 4 or the bottom of the evaporation crucible 4, the ultrasonic generator 1 is used to generate ultrasonic waves; Ultrasound; the controller 3 is used to determine the current metal source in the evaporation crucible 4 according to the waveform of the ultrasonic wave received by the acoustic wave receiver 2, and the preset relationship between the remaining amount of the metal source in the evaporation crucible 4 and the waveform of the ultrasonic wave. The remaining amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com