Imaging measurement method for gas holdup of gas-liquid two-phase flow of a single optical fiber array sensor

A gas-liquid two-phase flow, array sensor technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of limited success rate, small fiber probe size, and high gas phase sensitivity, so as to improve measurement accuracy and reduce Measuring the effect of blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

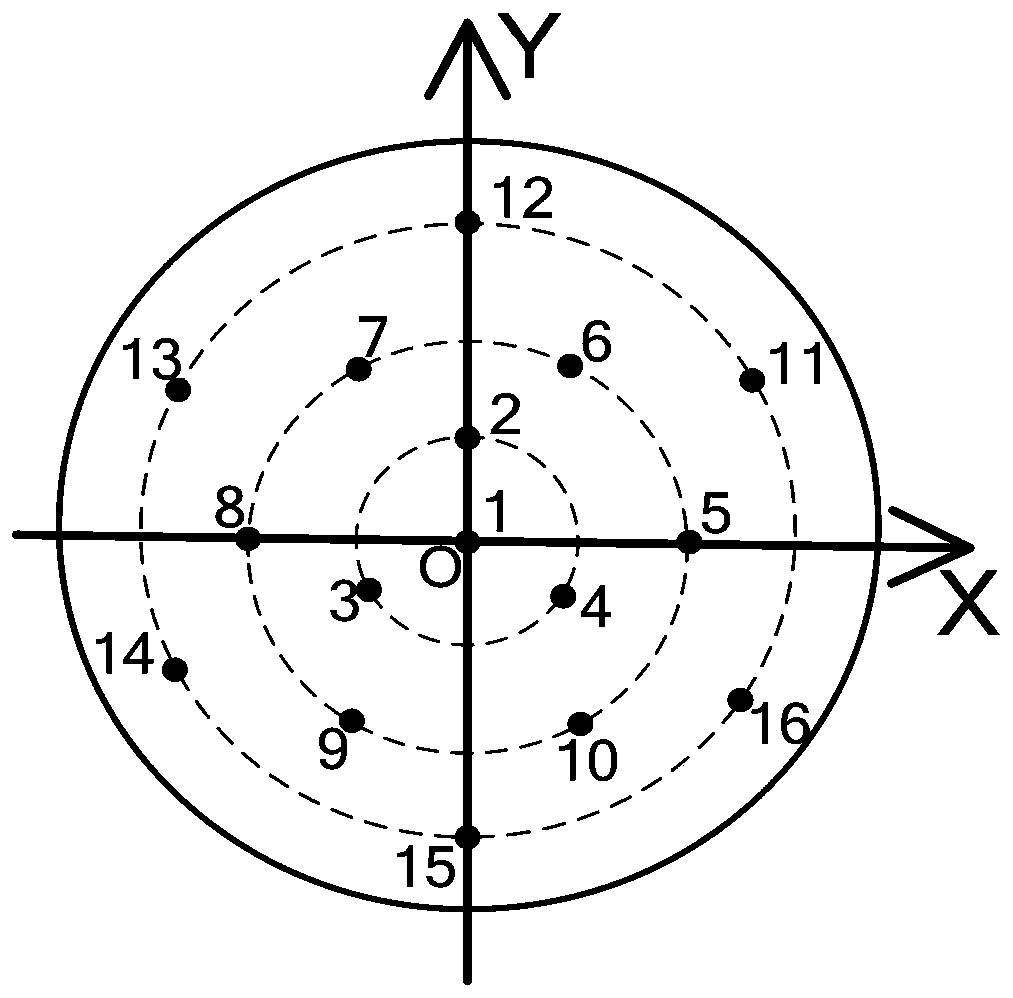

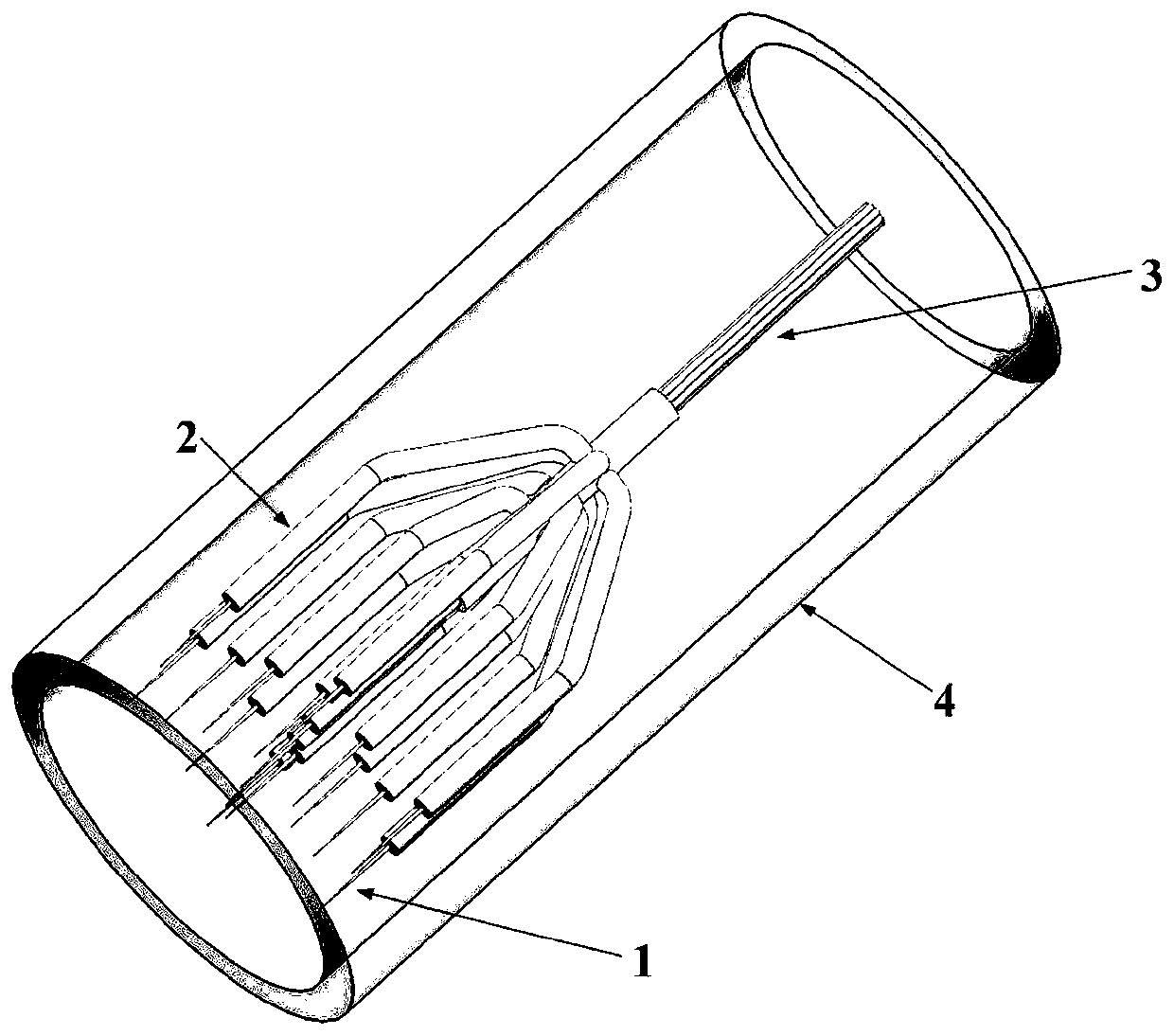

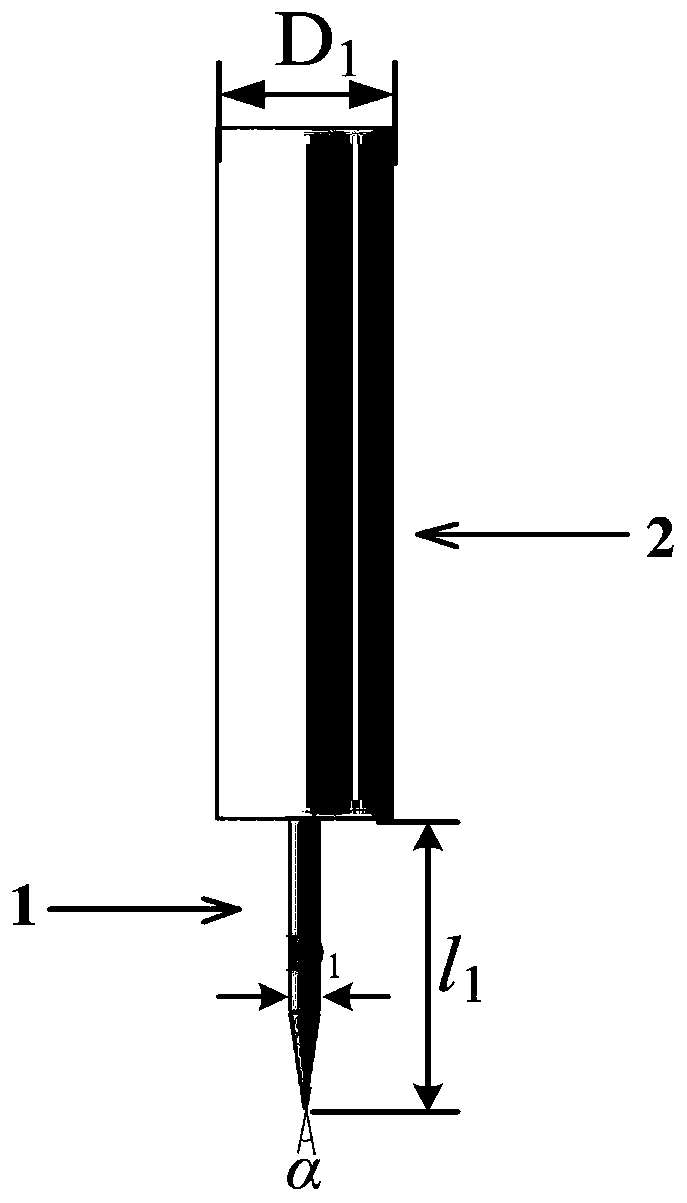

[0021] In order to investigate the distribution behavior of the gas holdup in the pipe section in the gas-liquid two-phase flow, the innovative idea of the present invention is to break through the measurement mode of the radial fiber probe in a single direction by adopting the distributed optical fiber probe measurement method, and propose a simultaneous A measurement method for capturing the local gas holdup at 16 measurement positions in the gas-liquid two-phase flow pipe section. In terms of measurement methods, 16 single-fiber probe sensors are placed in the small-diameter measurement pipe after the current collection. The 16-way fiber optic probes are distributed in four ring positions on the tube section, the first ring only contains 1-way probes, the second ring consists of 3-way probes, the third ring consists of 6-way probes, and the fourth ring consists of 6 composed of road probes. The probe position of each ring is reasonably placed through the geometric struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com