Near-infrared quality monitoring method for pharmaceutical granules

A technology for quality monitoring and granules, applied in measuring devices, material analysis through optical means, instruments, etc., can solve unsolved unsolved batch particle size uniformity and content uniformity, increase uniform mixing process, and reduce production efficiency and other problems, to achieve the effect of reducing the mixing process, reducing storage space and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The near-infrared quality monitoring method of Qingkailing granules comprises the following steps:

[0035] ①Qingkailing granule collects original near-infrared spectrum

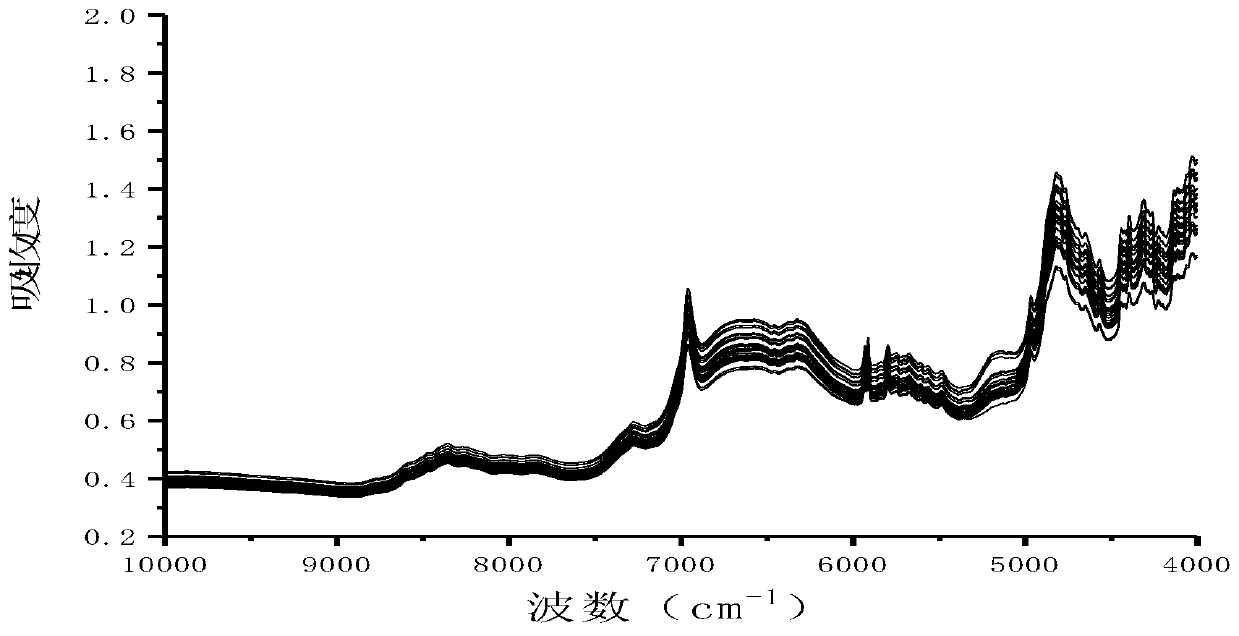

[0036] Near-infrared spectrum collection conditions: at room temperature of 15-30°C, use Zhejiang Concentrating Technology Online Near-Infrared Analysis System-4692 for data collection; the specific operating conditions are: the light source is a halogen tungsten lamp, and the detector is an InGaAs detector; , with a resolution of 8cm -1 , the number of scans is 32 times, and the scanning spectrum range is 10000~4000cm -1 . The near-infrared spectrum of Qingkailing granules scanned according to the above conditions is shown in figure 1 .

[0037] ② Determination of the content of index components in Qingkailing Granules

[0038] Adopt HPLC method to measure the content of geniposide in Qingkailing granule, table 1 is the content table of geniposide:

[0039] Table 1 Content table of geniposide i...

Embodiment 2

[0061] The near-infrared quality monitoring method of acetaminophen granules comprises the following steps:

[0062] ① Acetaminophen particles collect raw near-infrared spectra

[0063] Near-infrared spectrum collection conditions: at room temperature of 15-30°C, use Zhejiang Concentrating Technology Online Near-Infrared Analysis System-4692 for data collection; the specific operating conditions are: the light source is a halogen tungsten lamp, and the detector is an InGaAs detector; , with a resolution of 8cm -1 , the number of scans is 32 times, and the scanning spectrum range is 10000~4000cm -1 . The near-infrared spectrum of acetaminophen particles scanned according to the above conditions is shown in Figure 4 .

[0064] ② Determination of the content of index components of acetaminophen granules

[0065] Adopt HPLC method to measure the content of paracetamol in the paracetamol granule, table 4 is the content table of paracetamol:

[0066] Table 4 Paracetamol conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com