Ferromagnetic material defect detection system based on ultrasonic and magnetic flux leakage

A magnetic material and defect detection technology, which is applied to the magnetic variables of materials and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of increasing the complexity and cost of the detection system, low detection efficiency, etc., and achieve good application prospects and measurement accuracy The effect of high height and wide measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

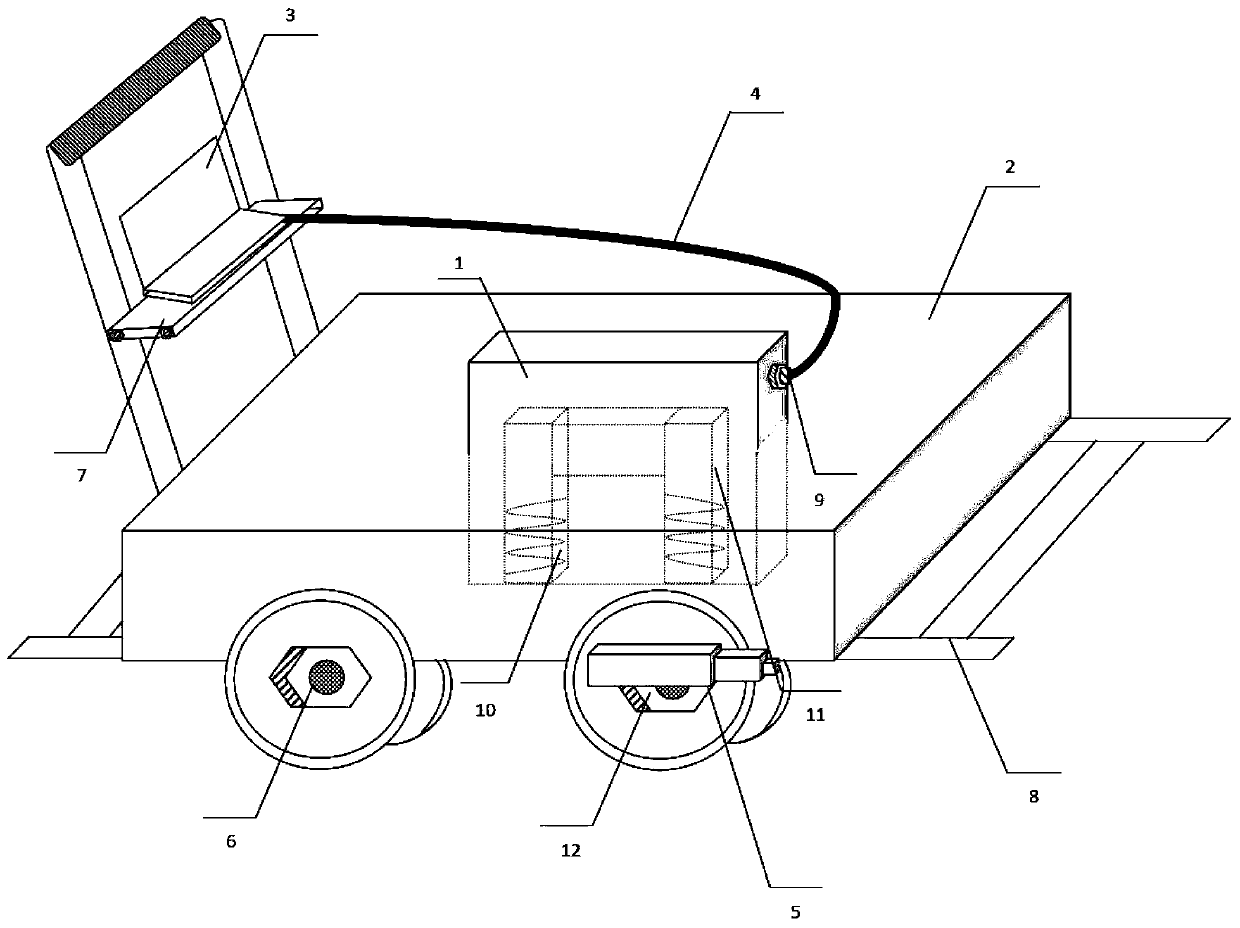

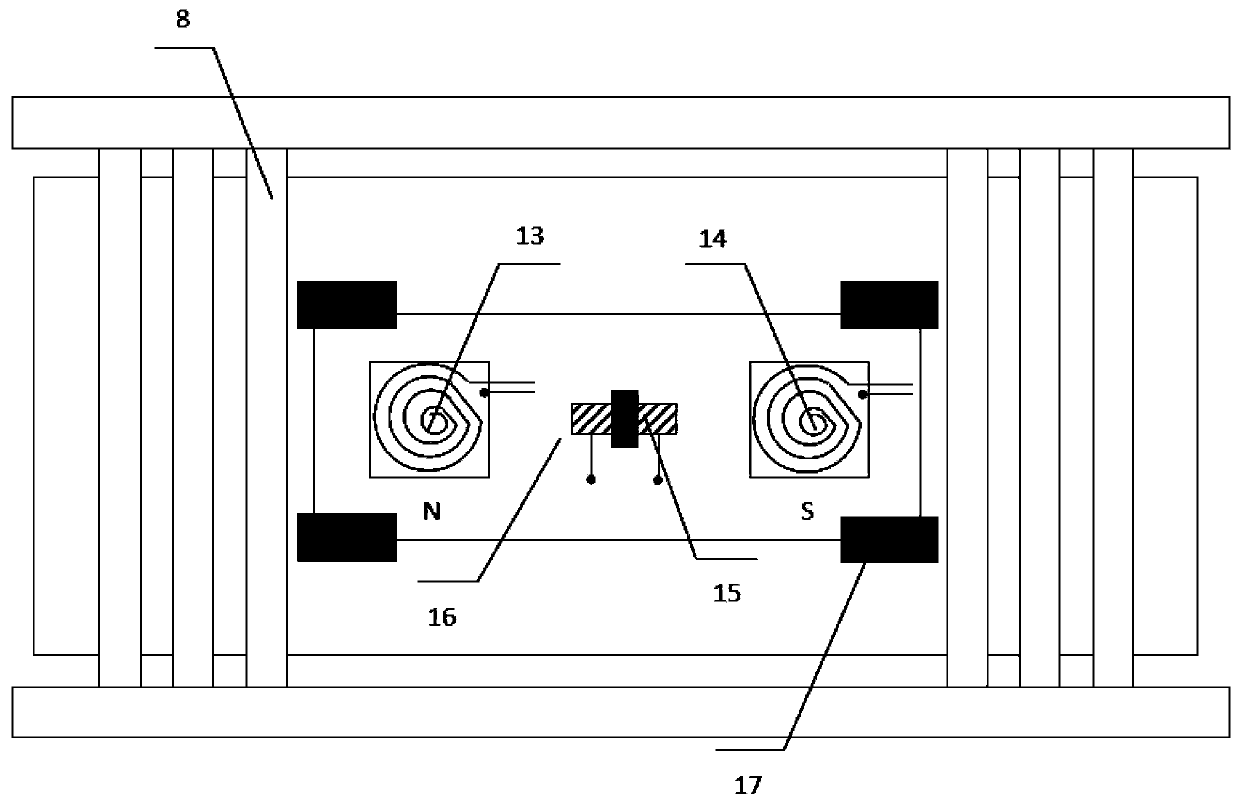

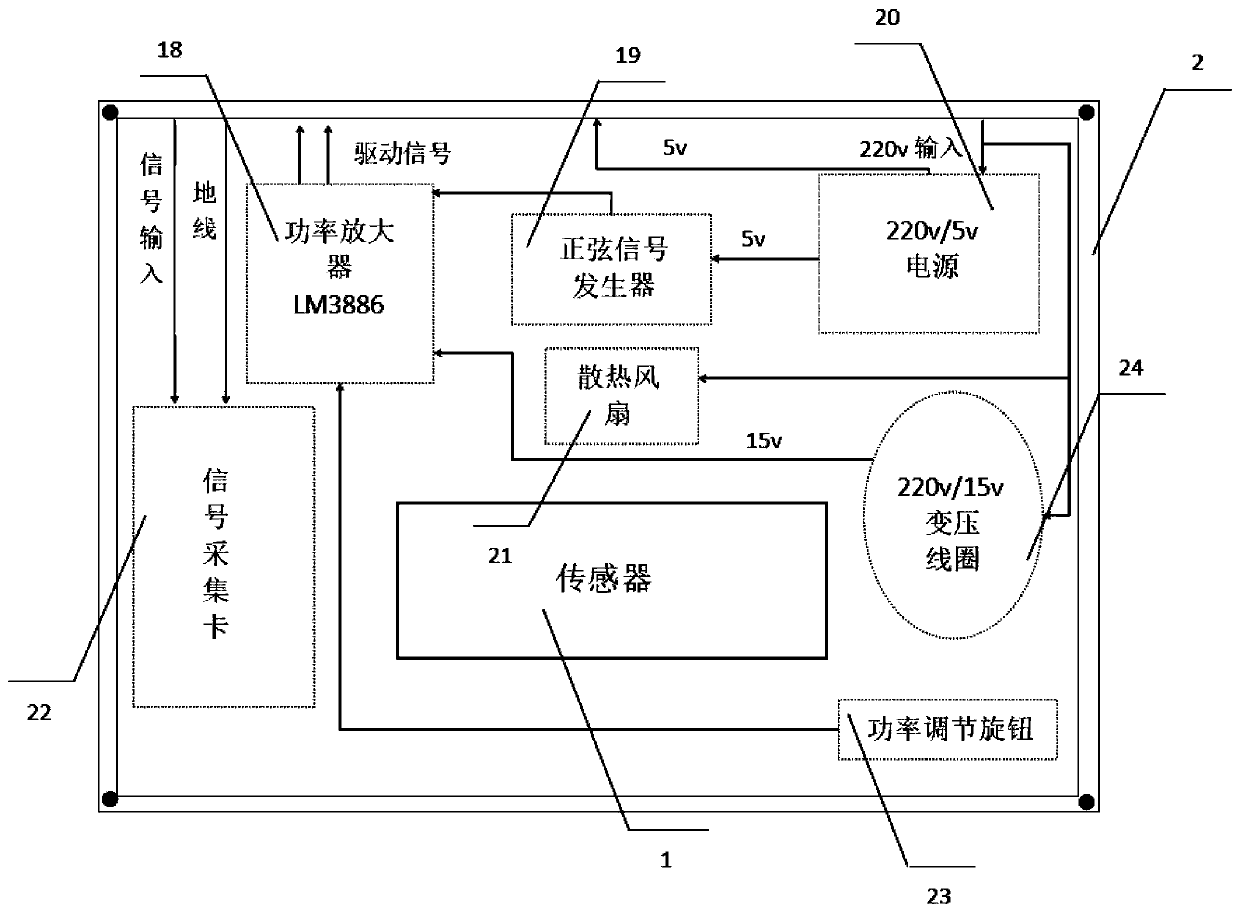

[0021] Ultrasonic combined with leakage magnet magnetic material defect detection system consists of sensor (1), host computer (2), computer (3), data upload line (4), motor (5), wheel (6), support plate (7), vehicle frame (8), through hole (9), coil (10), U-shaped magnetic core (11), driving wheel (12), N pole electromagnetic ultrasonic coil (13), S pole electromagnetic ultrasonic coil (14), Hall Er element (15), electronic potting glue (16), sensor holder (17) is formed. The host is composed of a power amplifier (18), a sine signal generator (19), a 220v / 5v power supply (20), a fan (21), a signal acquisition card (22), a sensor (1), a power adjustment knob (23), 220v / 15v transformer coil (24) is formed.

[0022] The sine signal generator (19) utilizes the DA of STM32 to output a sine wave modulated by PWM, and uses this signal as an excitation source to be amplified by a power amplifier (18). The main chip of the power amplification module is LM3886, and the output signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com