A glass cover for preventing liquid crystal display light leakage and its manufacturing method

A technology of liquid crystal display and glass cover plate, which is used in instruments, optics, nonlinear optics, etc. to achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] What is set forth below is what is presently considered to be the preferred embodiment, or best representative example, of the claimed invention. Any alteration or modification which substantially alters function, purpose, structure, or result, having considered future and present representations or modifications of the embodiments and preferred embodiments, is intended to be covered by the claims of this patent. Preferred embodiments of the invention will now be described, by way of example only, with reference to the accompanying drawings.

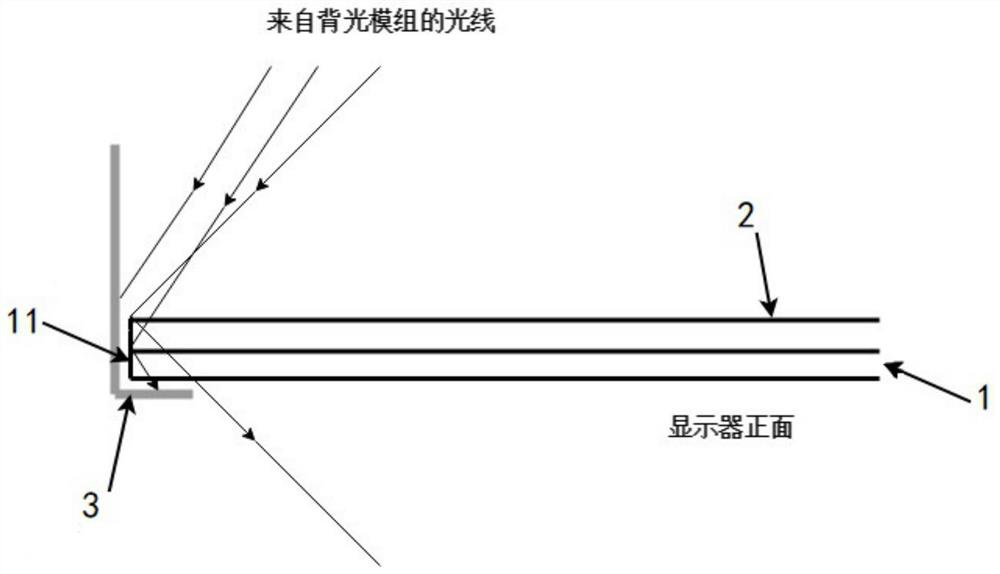

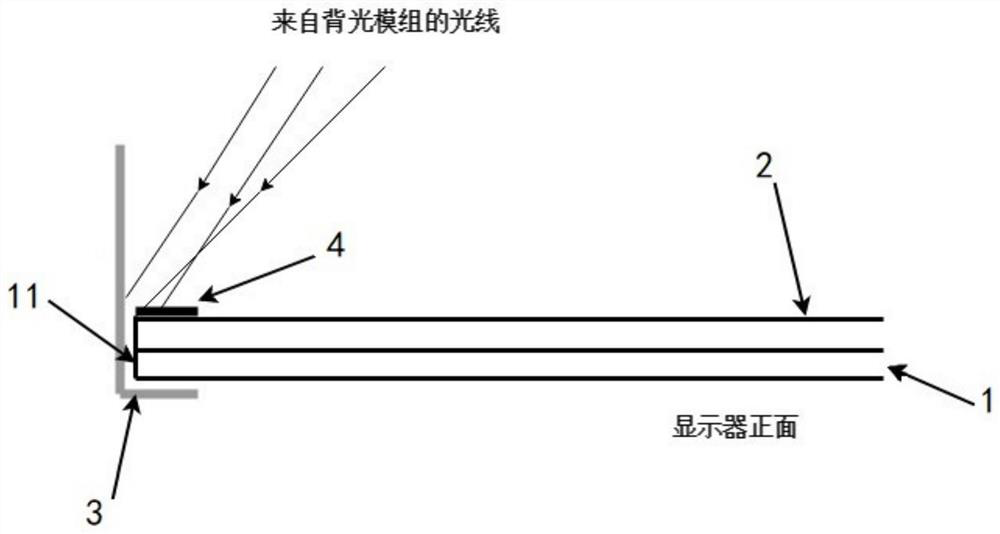

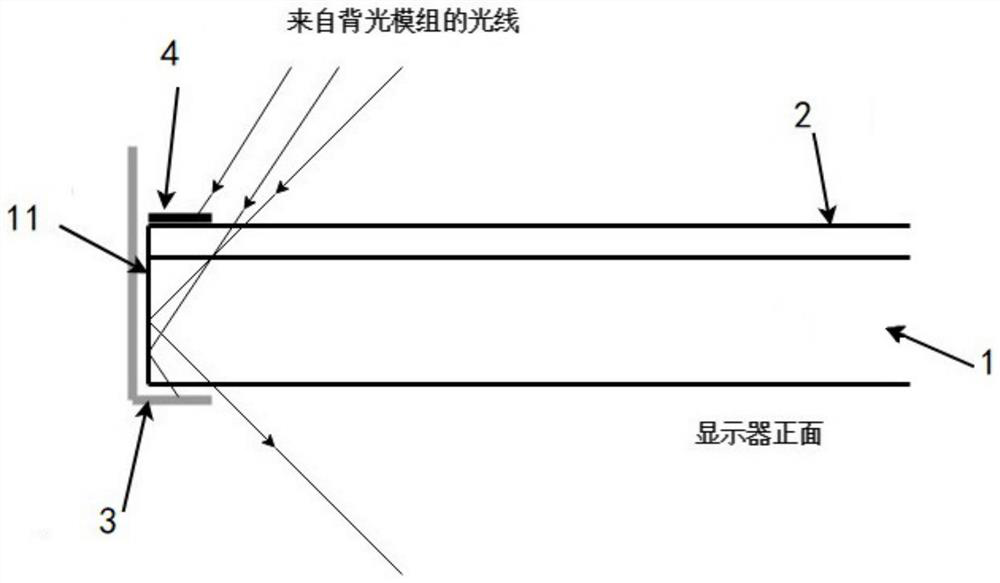

[0035] Figure 5 A schematic diagram showing the refraction and reflection of light on the end surface of the cover glass. exist Figure 5 The end surface 11 of the cover glass 1 shown in is a plane, and when the light falls on the end surface, it will be refracted or reflected depending on its incident angle. Assume that the refractive index of the optically rarefied medium is n 1 , the refractive index of the optically dense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com