Method for extending length of cable

A cable length and cable technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve problems such as easy breakdown, large joint size, and large difference between the insulation layer and the original cable, and achieve reliability and High stability, good waterproof performance, no visible discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solutions and advantages of this application clearer, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments. Obviously, the described embodiments are only a part of the application Examples, not all examples.

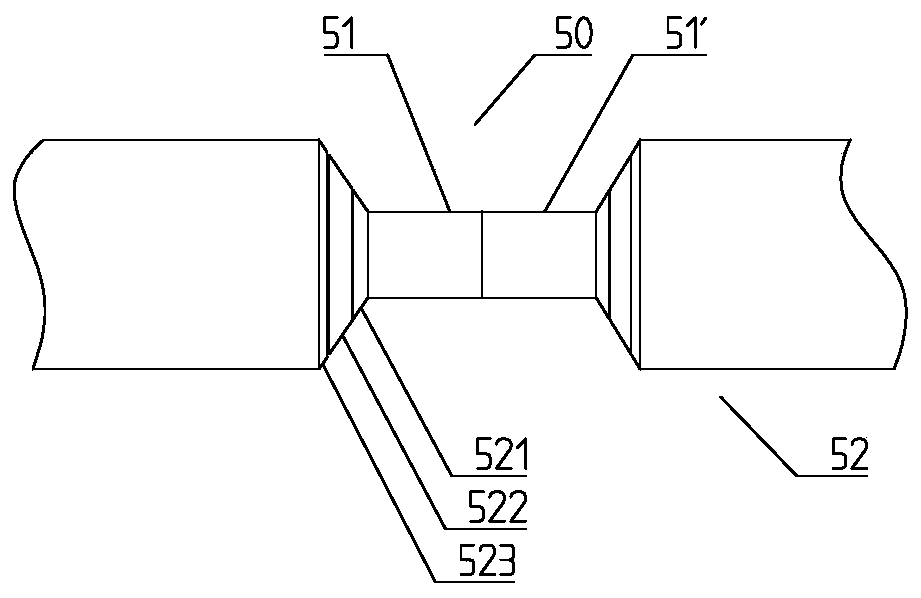

[0056] A method of extending the length of a cable comprising

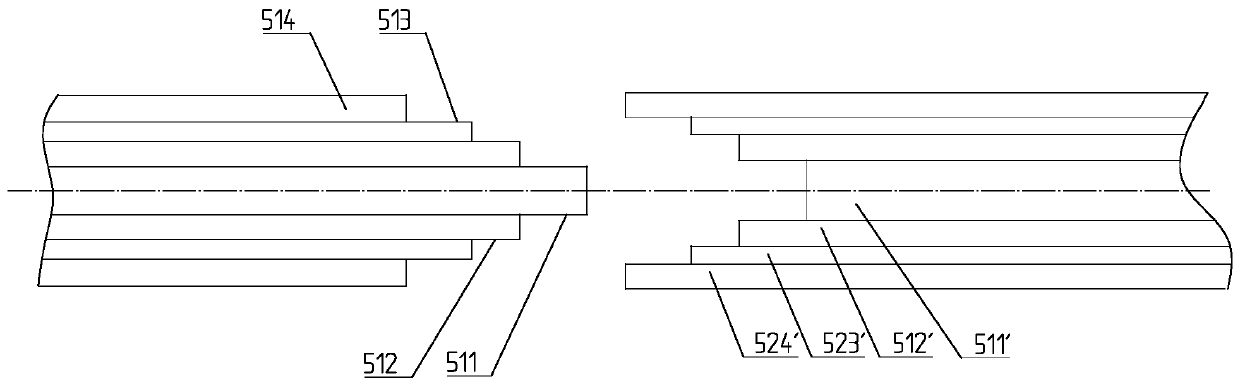

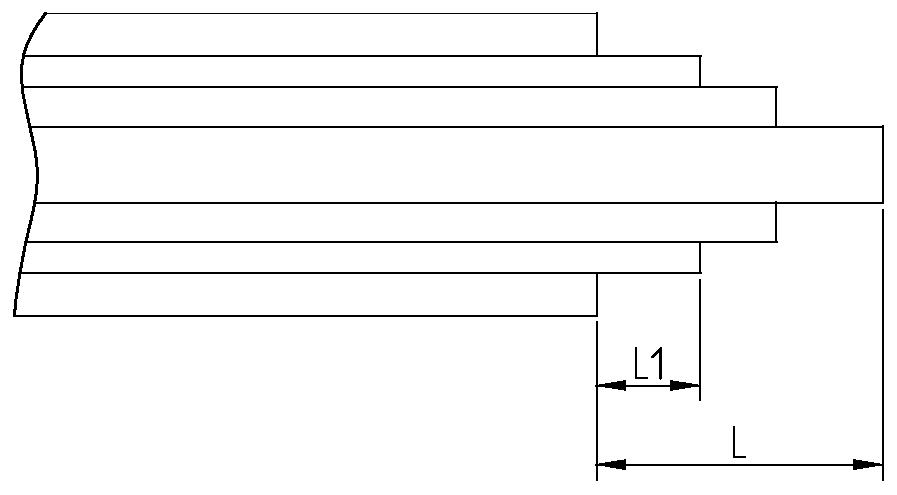

[0057] S1: Cut the insulating layer at the end of the two cables to be connected, and expose the conductor of the inner wire; specifically, remove the insulating layer of the cable; the total length of the end insulating layer 52 of the two cables to be connected is 30-35cm , that is, the length of each end is 15-17.5cm, the incision of the insulating layer 52 is a cone angle, and the angle is preferably 30 degrees;

[0058]S2: Use flame-retardant and refractory cloth to fasten the bodies of the two cables close to the cutout for protection;

[0059] S3: Safel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com