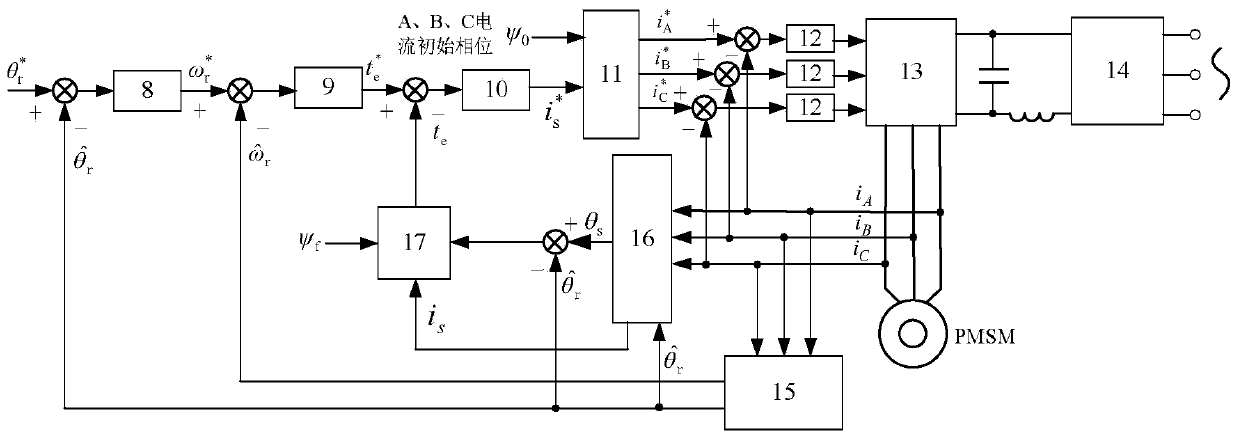

Permanent magnet/reluctance dual-rotor low-speed and high-torque synchronous motor and control system thereof

A synchronous motor, double rotor technology, applied in the direction of electronic commutation motor control, control system, vector control system, etc., can solve the problems of low operation efficiency, high cost, poor system reliability, etc., and achieve high material utilization and low cost. , Improve the effect of reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

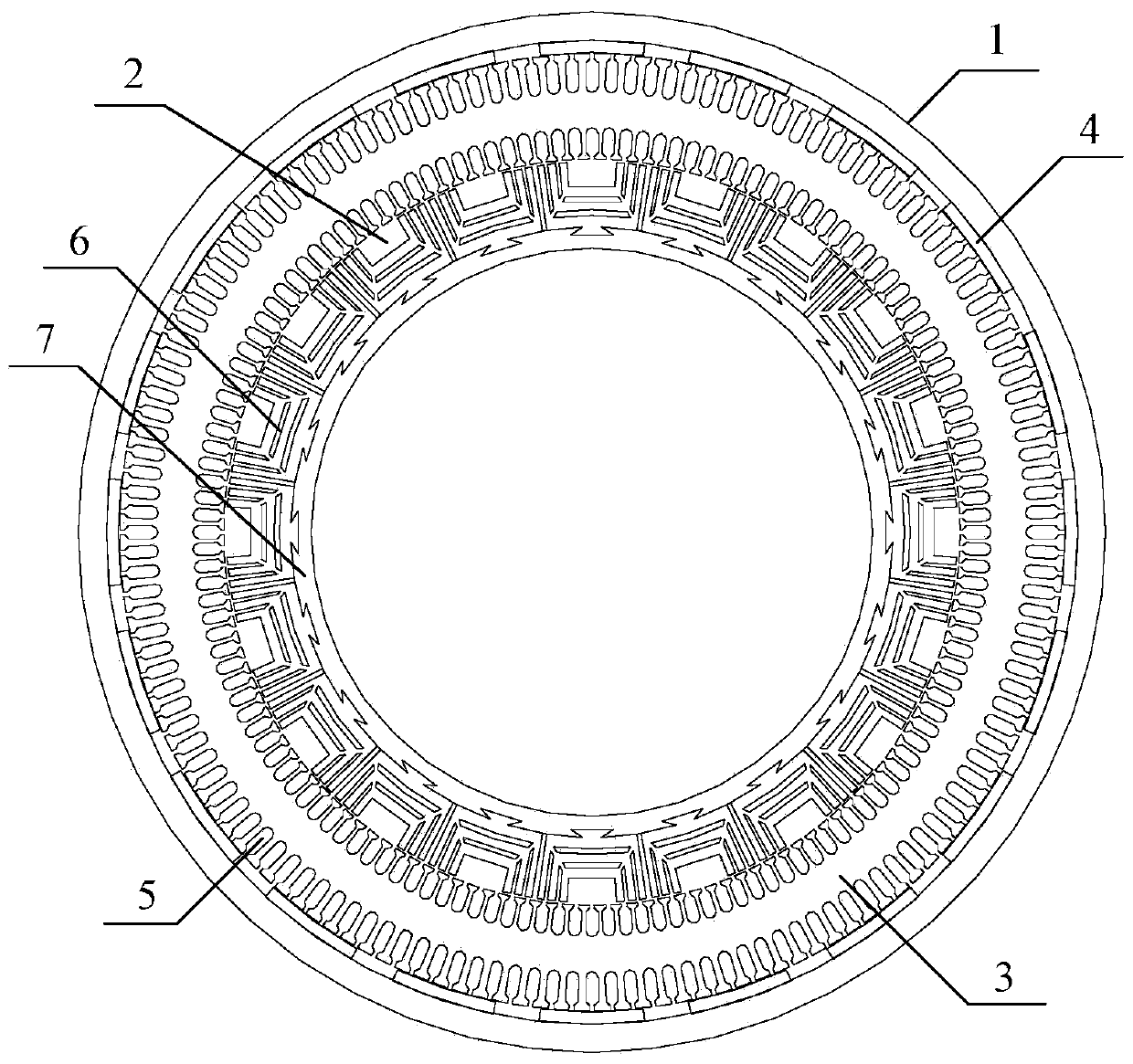

[0032] The permanent magnet / reluctance dual-rotor low-speed high-torque synchronous motor is characterized in that: the synchronous motor is mainly composed of an outer rotor (1), an inner rotor (2) and a stator (3); the stator (3) is arranged on the outer rotor (1 ) and the inner rotor (2);

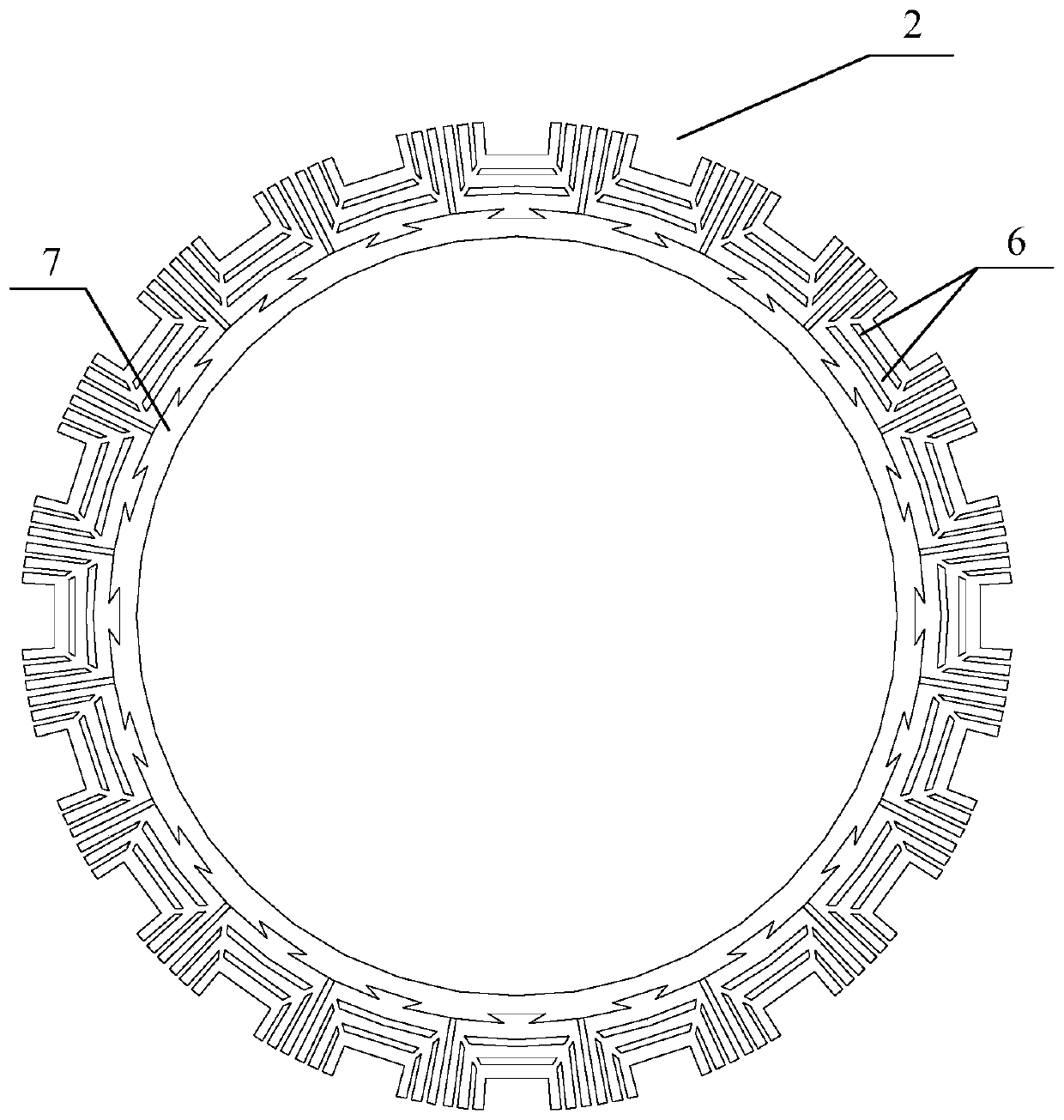

[0033] The inner rotor (2) includes a magnetic isolation ring (7) (2-1) and a magnetic barrier reluctance rotor structure (6), and the magnetic barrier reluctance rotor structure (6) is composed of a magnetic permeable layer (6-1) and The non-magnetic-permeable layers (6-2) are alternately formed, each magnetic barrier reluctance rotor structure (6) is fixed on the outer wall of the magnetic isolation ring (7) through the dovetail groove, and the magnetic barrier reluctance rotor structure (6) is set Between the magnetic isolation ring (7) and the stator (3);

[0034] A permanent magnet (4) is arranged inside the outer rotor (1);

[0035] The inner and outer surfaces of the stator (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com