Method for treating and recycling liquid organic kitchen wastes

A kitchen waste and recycling technology, applied in organic fertilizers, climate change adaptation and other directions, can solve the problems of difficult to remove odor or peculiar smell of materials, long fermentation time, and low efficiency of the direct fermentation process of liquid organic kitchen waste. Shortened processing time, high added value, and obvious effects of increasing production and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation of Aspergillus fumigatus NJZ5 bacteria liquid includes: Activation of bacteria: take out the spores of Aspergillus fumigatus NJZ5 preserved at -80°C, inoculate them on a solid PDA plate with an inoculation loop, cultivate them at 45°C for 48 hours, and activate them; preparation of spore suspension: put the activated The bacteria were inoculated into a 250mL Erlenmeyer flask containing 50ml of solid PDA medium, cultured at 45°C for 3 to 4 days, added 10ml of high-temperature sterilized 0.9% NaCl solution under sterile conditions, shaken at 120rpm for about 30min, and then used Filter two layers of sterile gauze to remove mycelia and sporangia to obtain a spore suspension; culture: use a 250mL Erlenmeyer flask to fill 50mL of PDA liquid medium, insert the spore suspension to a final concentration of 1×10 7 cells / mL, shake culture at 45°C and 200 rpm for 24 hours to obtain the Aspergillus fumigatus NJZ5 bacterial liquid with a dry mycelium density of 8.0 g / ...

Embodiment 1

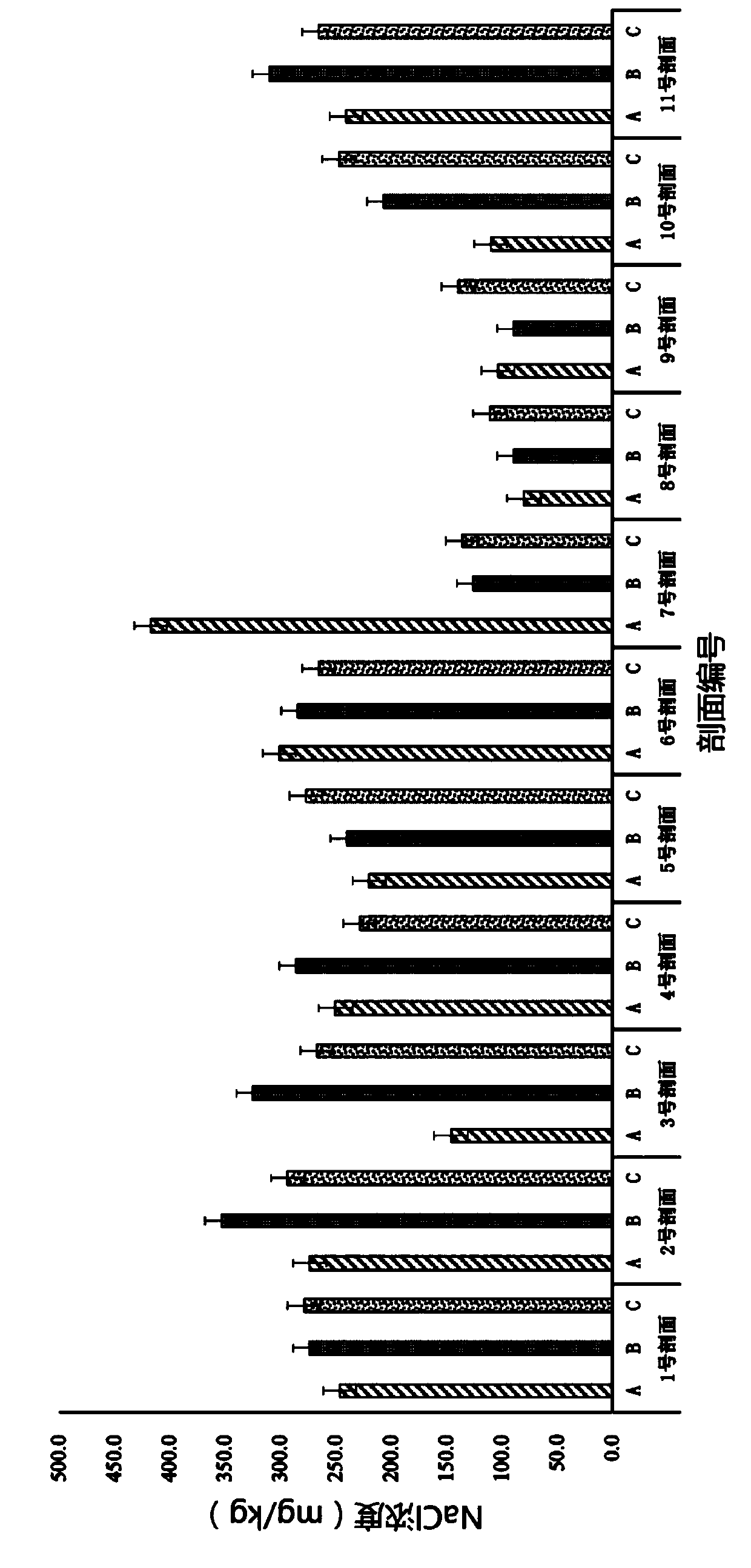

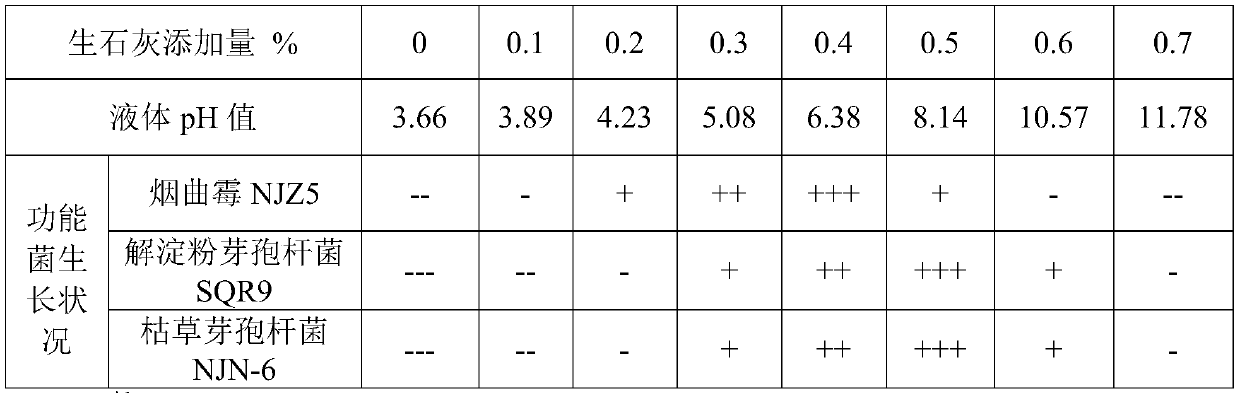

[0036] Take 8 parts of liquid organic kitchen waste (the same below) and put them into the treatment tank respectively, add different amounts of solid quicklime powder (as shown in Table 1), stir and mix for 6 hours, and measure the pH value. At room temperature of 32°C, the pH-adjusted liquid organic kitchen waste was inserted into Aspergillus fumigatus NJZ5 bacterial liquid (dry mycelium density of 8.0 g / L), Bacillus subtilis NJN-6 bacterial liquid (density of 10 10 CFU / ml), Bacillus amyloliquefaciens SQR9 bacteria liquid (density 10 10 CFU / ml), the inoculum amount of each functional bacterium is 2% (V / V), after the inoculation of the functional bacterium, pass through the sterilizing air for 5 minutes every 3 hours to ensure that the liquid is in an aerobic fermentation state, and treat for 7 days .

[0037] According to the culture conditions of the three functional bacteria, 8 parts of the fermented liquid kitchen waste were spread on the corresponding plates, and the gr...

Embodiment 2

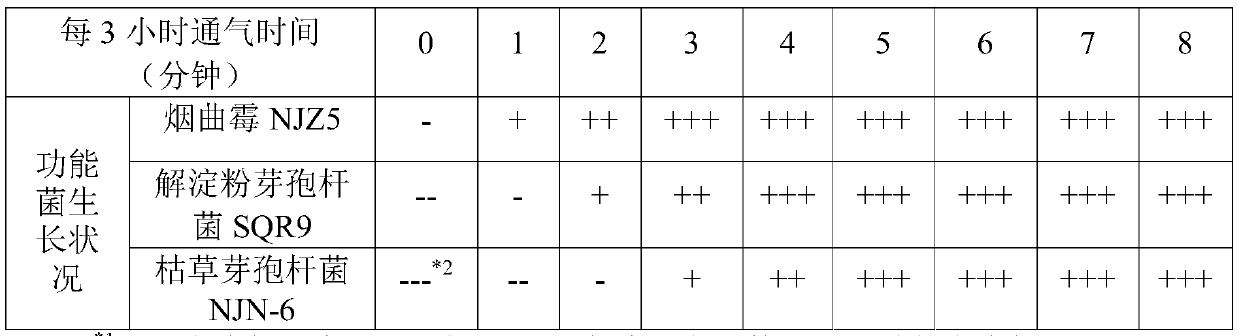

[0044] Get 9 parts of liquid organic kitchen waste (same as Example 1) and put them into the treatment tank respectively, add solid quicklime powder according to the dosage of 0.4%, and stir and mix for 6 hours. At room temperature of 32°C, the pH-adjusted liquid organic kitchen waste was inserted into Aspergillus fumigatus NJZ5 bacterial liquid (dry mycelium density of 8.0 g / L), Bacillus subtilis NJN-6 bacterial liquid (density of 10 10 CFU / ml), Bacillus amyloliquefaciens SQR9 bacteria liquid (density 10 10 CFU / ml), the inoculum amount of each functional bacterium is 2% (V / V), after inoculating the functional bacterium, according to Table 2, pass into sterilized air every 3 hours to ensure that the liquid is in an aerobic fermentation state, and the treatment 7 days.

[0045] According to the culture conditions of the three functional bacteria, 9 parts of the fermented liquid kitchen waste were spread on the corresponding plates, and the growth of the strains was observed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com