Rod-shaped object surface defect detection system and method based on machine vision

A technology for object surface and defect detection, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve problems such as poor reliability and low efficiency, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

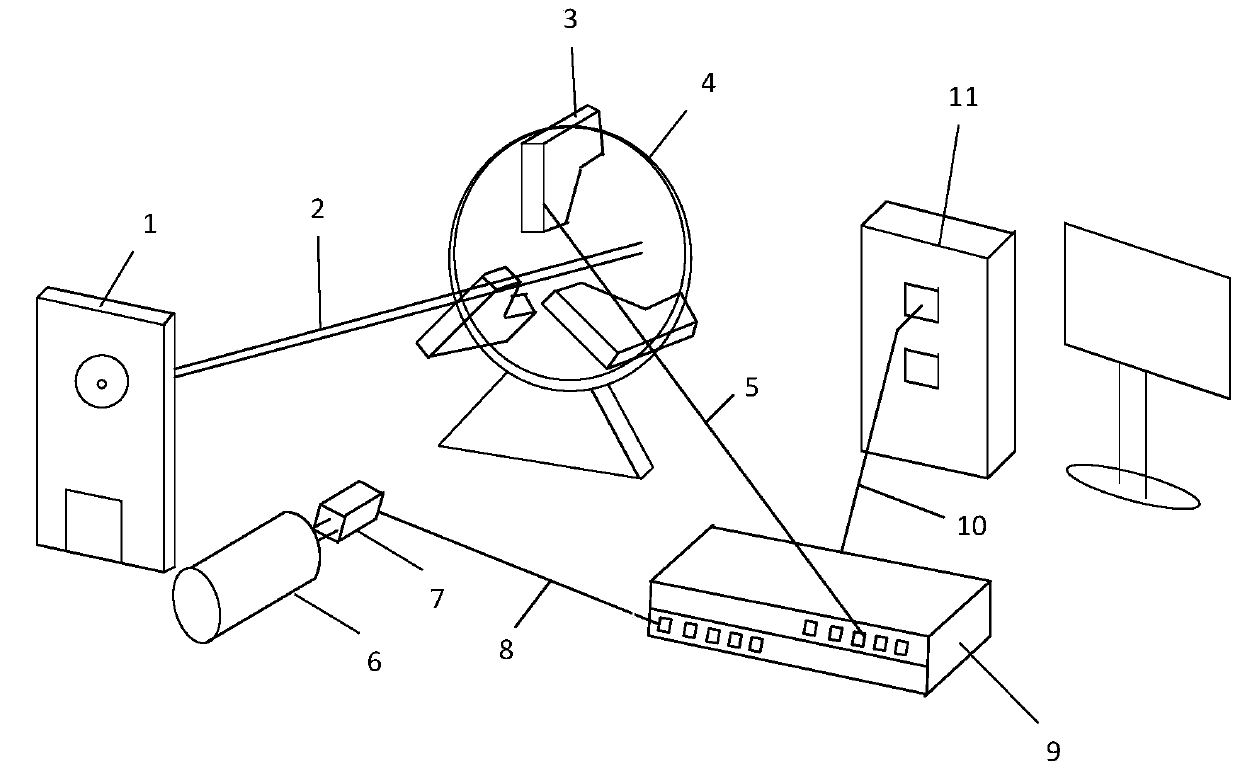

[0051] see figure 1As shown, the present invention provides a machine vision-based surface defect detection system for rod-shaped objects, including a 3D sensor 3 , a sensor bracket 4 , an encoder 7 , a main controller 9 and a graphics workstation 11 .

[0052] The rod-shaped object 2 is fixed by the tractor 1 and passes through the center of the sensor bracket 4. A plurality of 3D sensors 3 are fixed on the slider of the circular track of the sensor bracket 4 through a manual translation platform at a certain angle at intervals. The 3D sensors 3 pass through the main control line. 5 is connected to the main controller 9, the main controller 9 is connected to the power supply and the encoder 7 through the cable 8, the encoder 7 is fixed on the rotating shaft of the tractor 6, and the communication between the main controller 9 and the graphic workstation 11 is carried out through Ethernet .

[0053] The 3D sensor 3 includes a laser emitter, a CCD camera, an I / O connector and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com