Method for testing pH value of a concrete pore fluid

A pore liquid and concrete technology, applied in the field of pH testing, can solve the problems of a large number of test blocks, high operation cost of extrusion method, complicated operation of leaching method, etc., and achieve the effect of low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

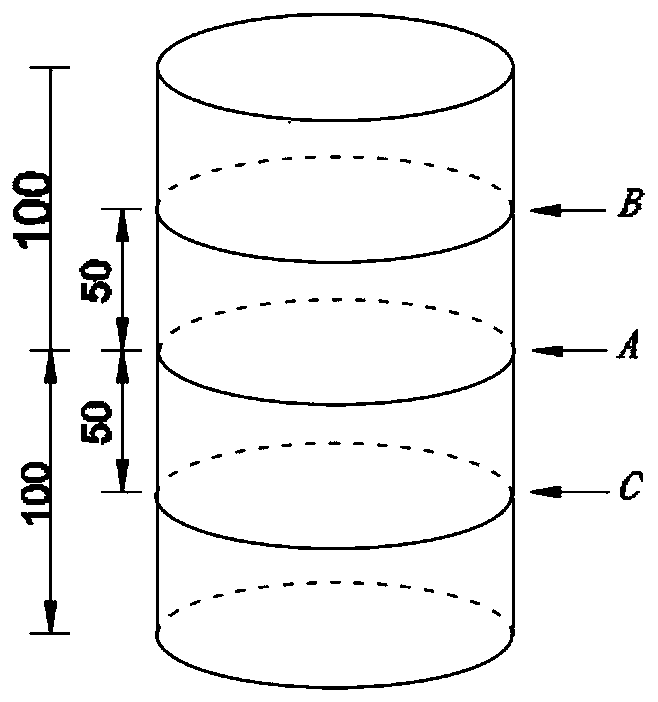

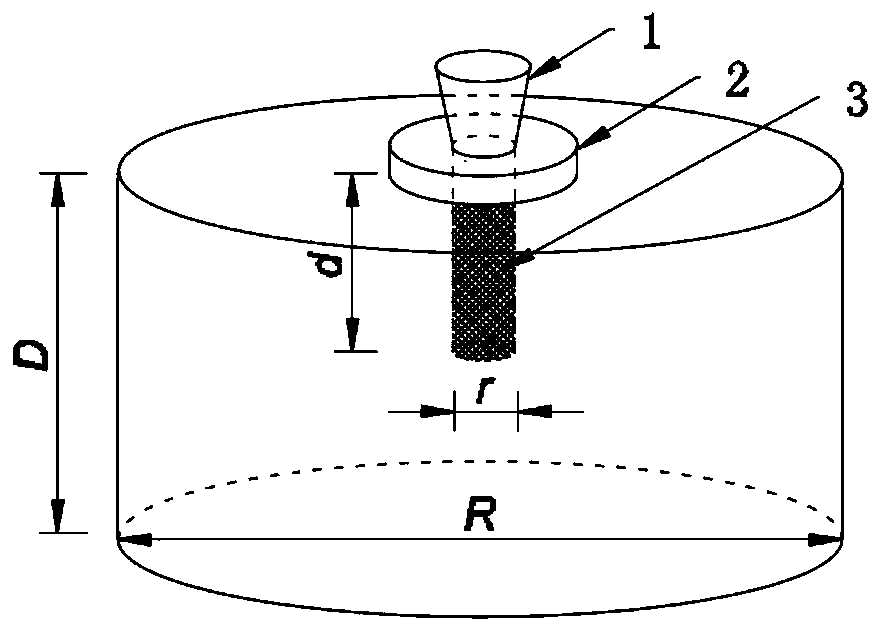

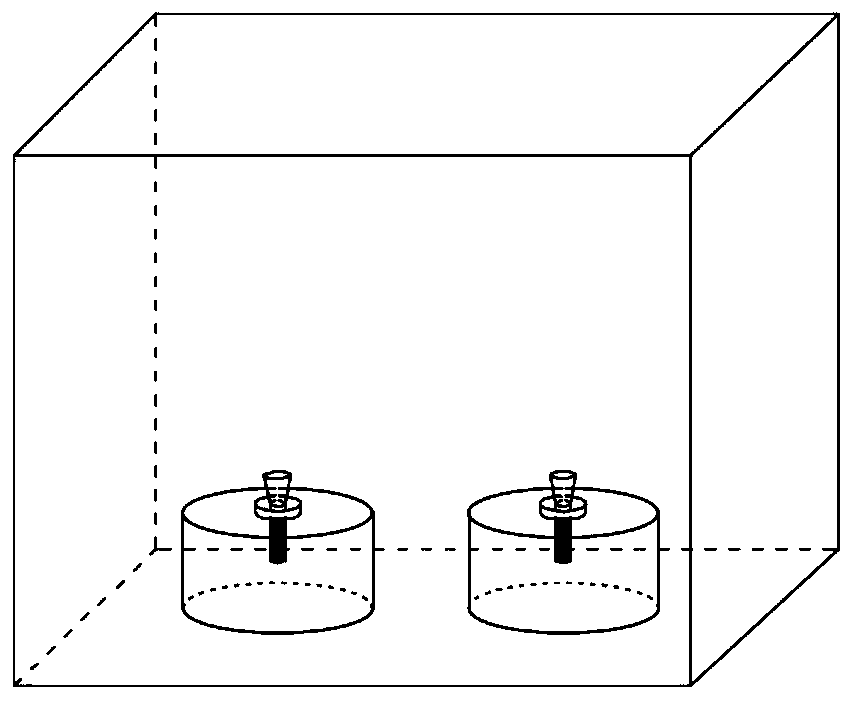

[0022] A method for testing the pH value of concrete pore liquid, the method uses a cylindrical concrete test block, drills holes in the test block and injects distilled water, and tests the pH value of the concrete pore liquid by ion precipitation. The method is divided into two stages: specimen preparation and testing. The first stage includes concrete test block cutting, cutting section drilling, plexiglass plate covering, distilled water filling, orifice sealing treatment, specimen storage, etc.; the second stage is pH value test. Cut the concrete to be tested according to the requirements, and drill holes in the test block, seal the perforated plexiglass on the orifice of the test piece, add distilled water and seal it with a rubber stopper. Store the processed test block in an environmental test chamber with 100% humidity and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com