Optimization and control method of stamping process for high-strength integral side wall of passenger car

A high-strength, passenger vehicle technology, applied in forming tools, metal processing, manufacturing tools, etc., can solve the problems of increasing cracking tendency, increasing the difficulty of design and manufacturing, and achieve optimal control, suppression of local cracking defects, The effect of solving the problem of insufficient inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

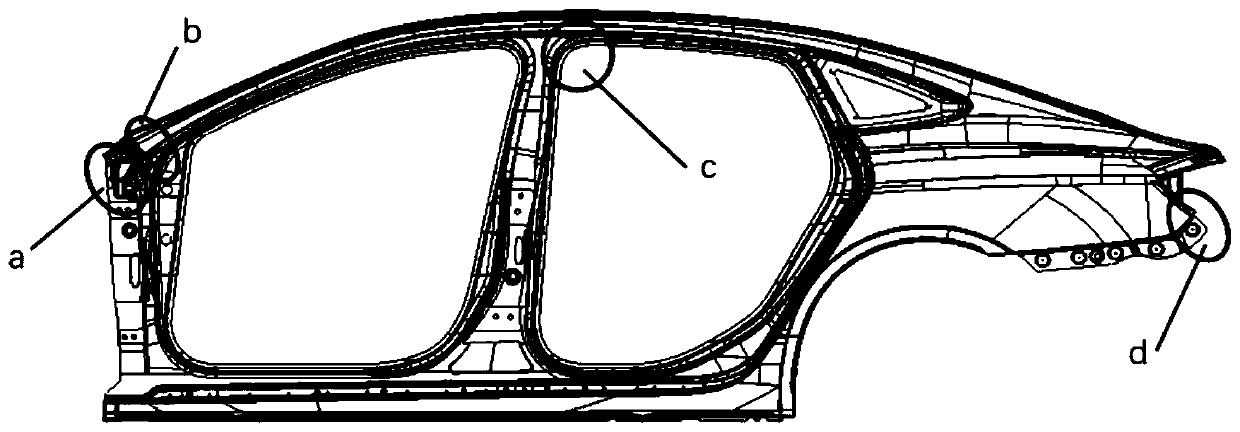

[0080] The overall side wall in this embodiment comes from the digital model of the actual vehicle, and the tensile strength level of the material used is 500MPa. The overall side wall with a tensile strength below 300MPa has better formability, and the corresponding solution proposed in this patent can also be adopted according to the structure type of the local easy-to-break area.

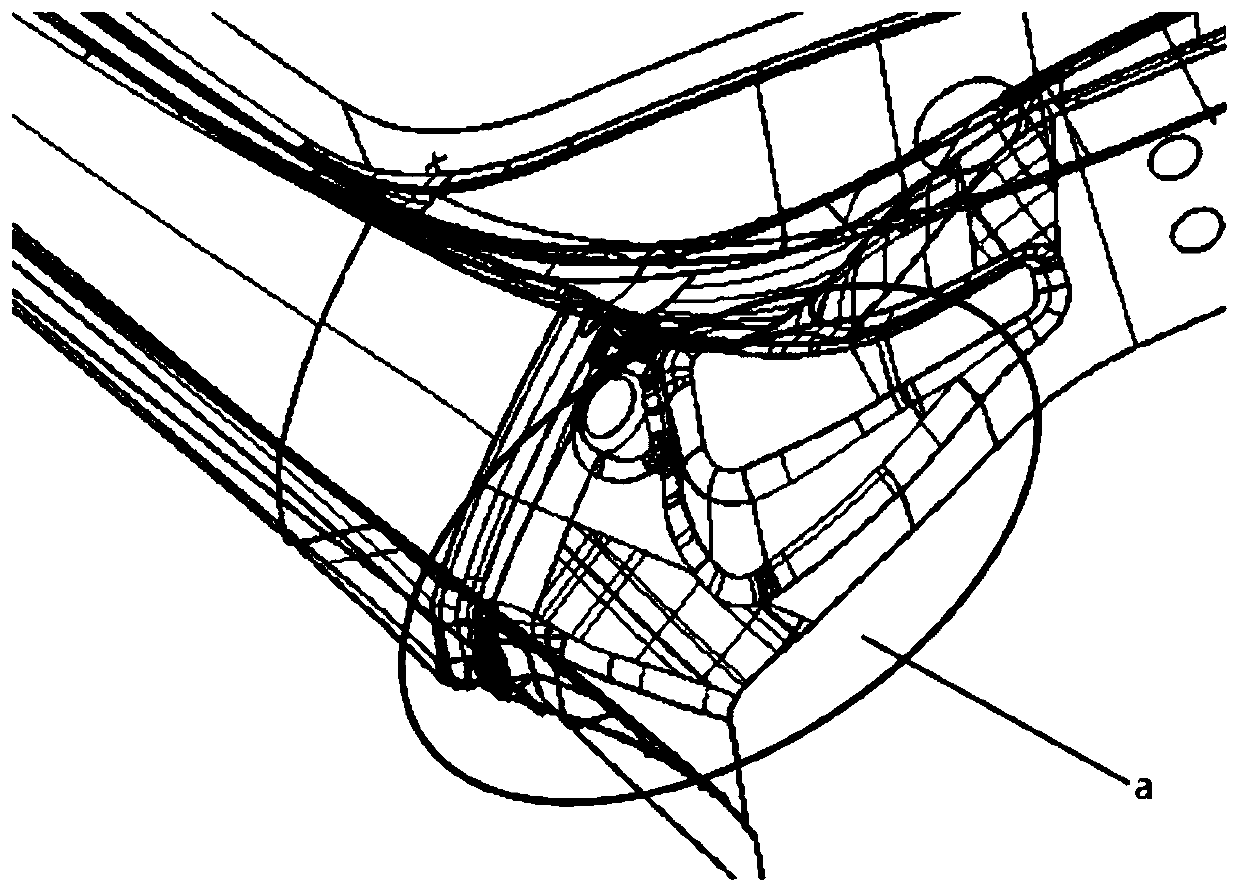

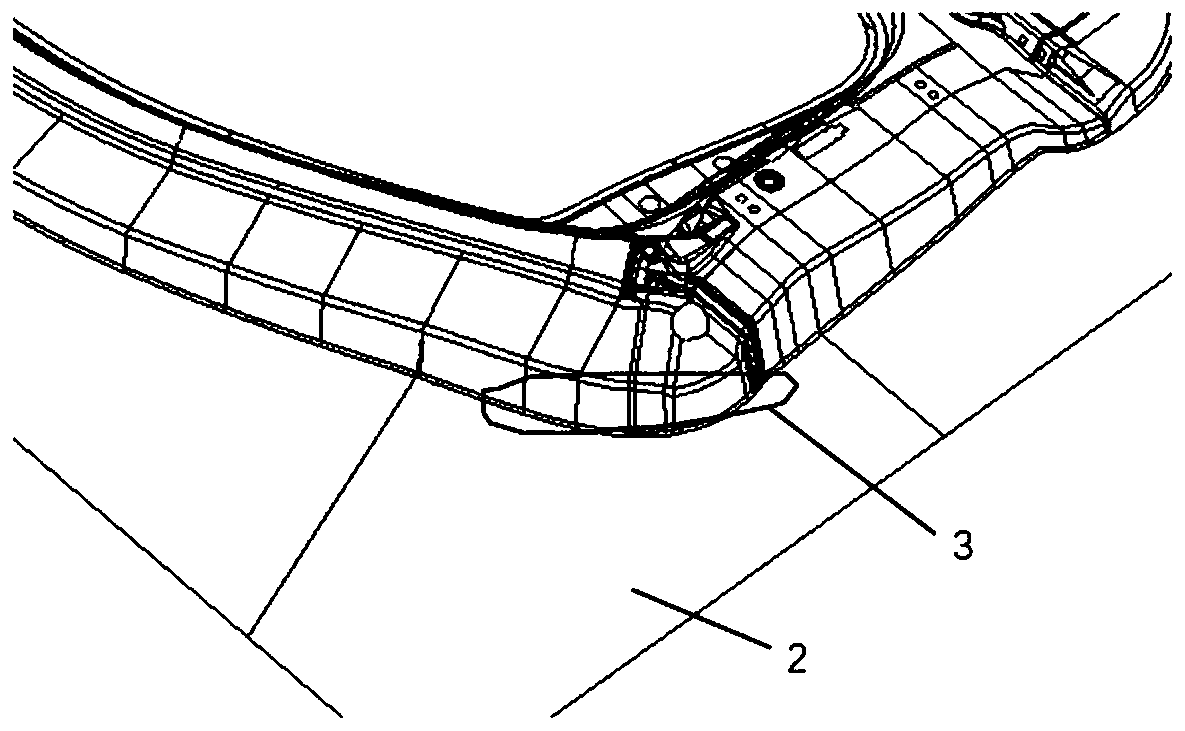

[0081] The present invention first analyzes the structure and forming characteristics of the overall side wall, and divides the local difficult-to-form structures into four categories: (1) locally complex and difficult-to-form structures; (2) locally sharp and difficult-to-form structures; (4) The structure of the arc-shaped flanging of the inner hole. Then, different control methods are designed for different types of local difficult-to-form structures.

[0082] 1. For locally complex and difficult-to-form structures: For locally complex and difficult-to-form structures, the present invention a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com