Ultrahigh-molecular weight modified polysiloxane, preparation method thereof, and application thereof in plastic processing

An ultra-high molecular weight, polysiloxane technology, applied in the field of polymer materials, can solve the problems of low reactivity, poor compatibility, easy precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

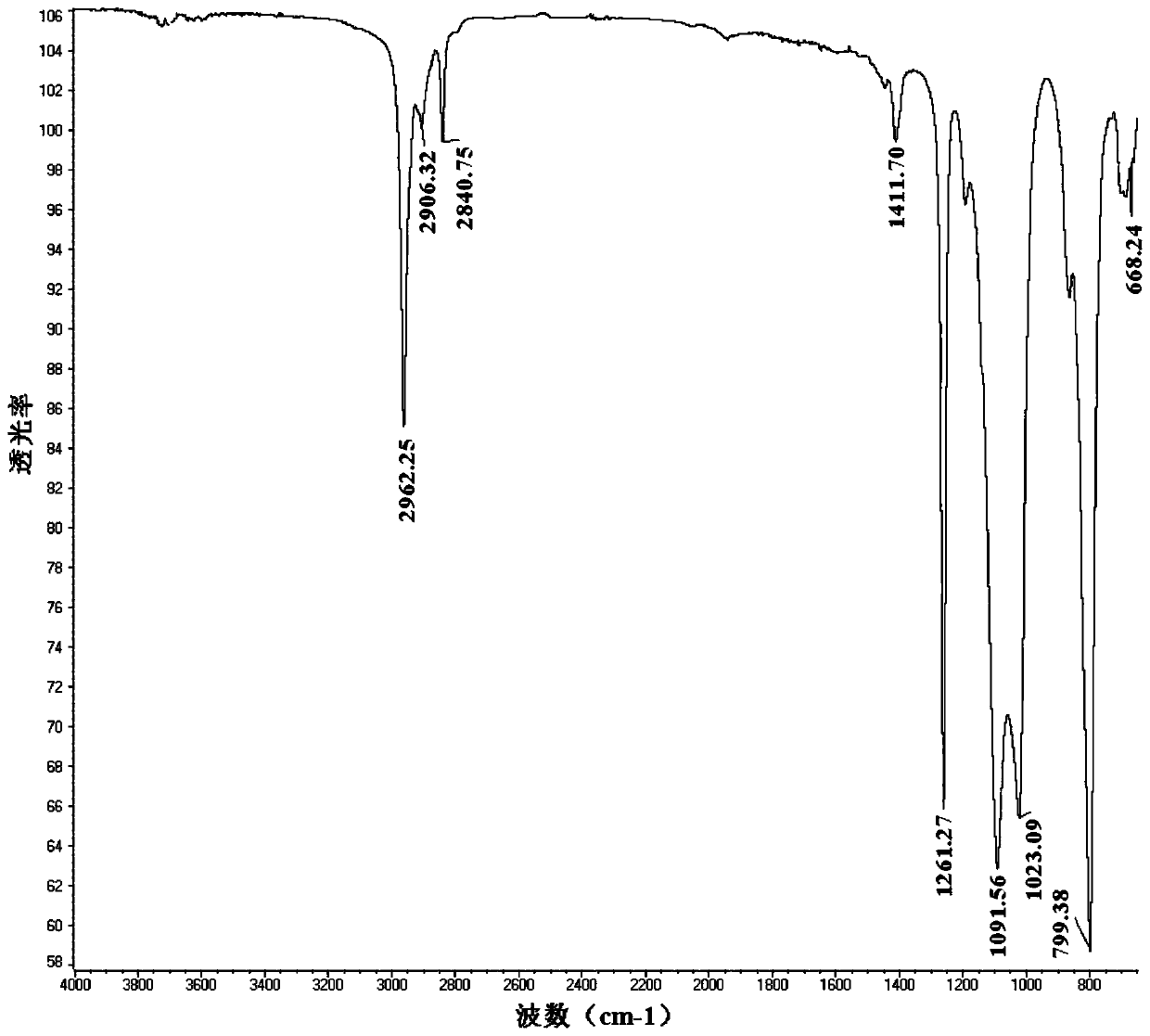

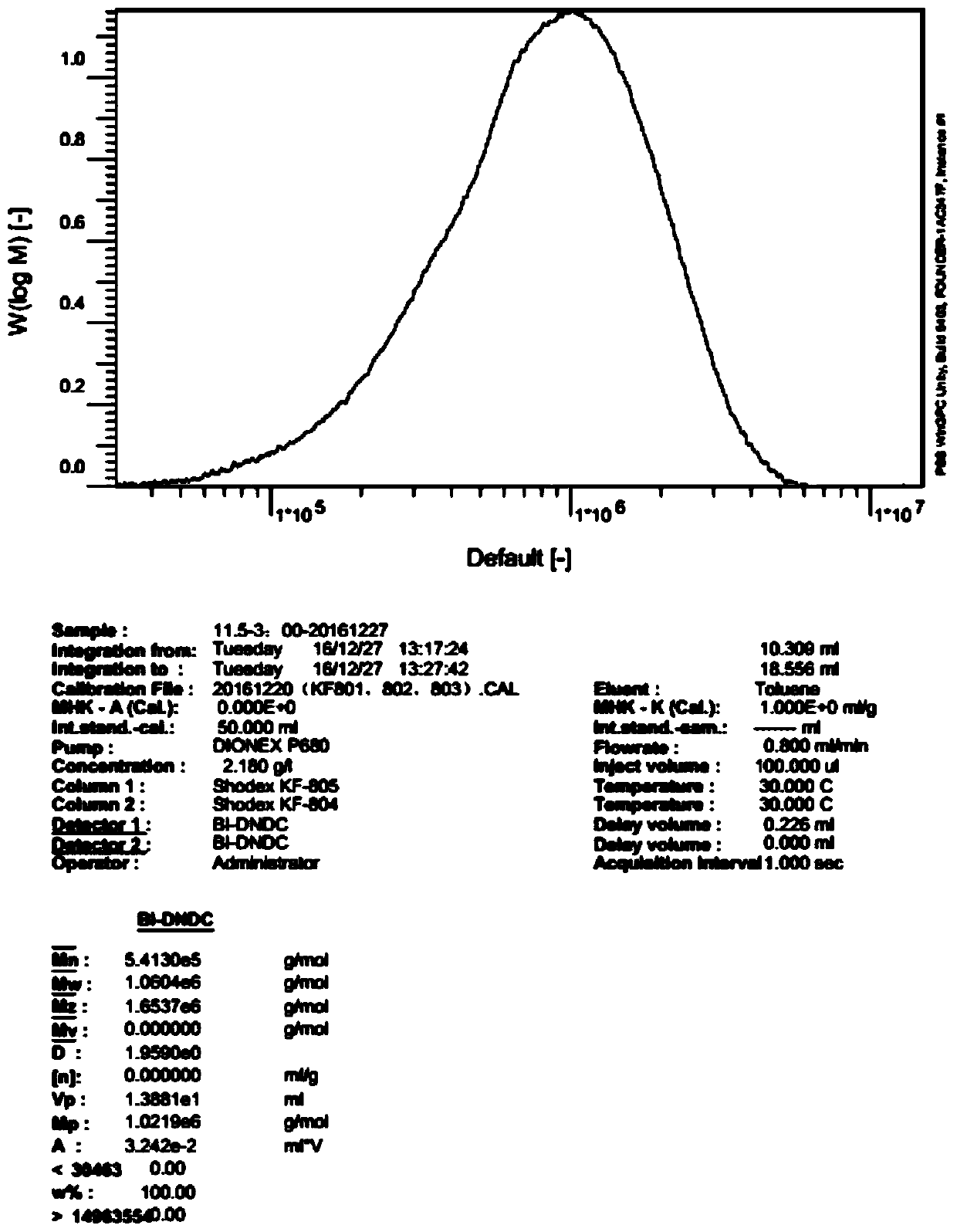

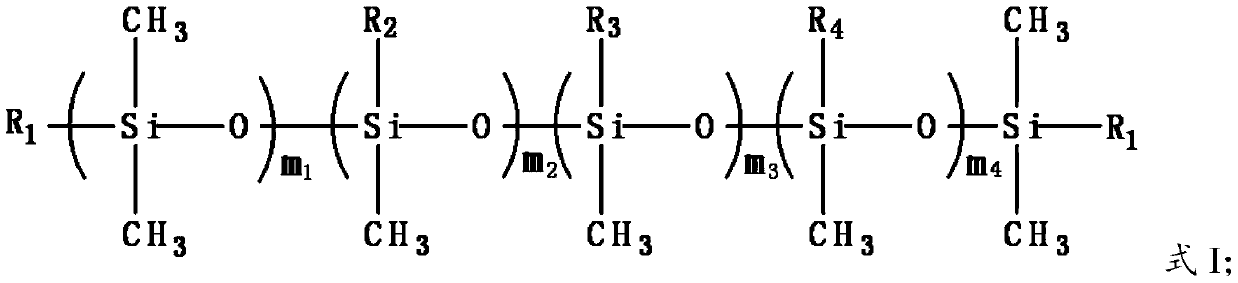

[0111] Embodiment 1 Long-chain alkyl modified ultrahigh molecular weight modified polysiloxane

[0112] (1) Preparation of long chain hydrocarbon alkyl modified silane

[0113] Add 1-tetradecene dropwise to the toluene mixed solution of methyldichlorosilane and platinum catalyst, the platinum catalyst is Speier catalyst, and the amount of catalyst is 1 / 10,000 of the total mass of reactants, calculated by platinum atomic mass, 1-10 The molar ratio of tetraene to methyldichlorosilane was 1.1:1, the reaction temperature was 80°C, and the reaction was carried out for 4 hours. After the reaction, the unreacted raw materials and solvent were evaporated to obtain tetradecylmethyldichlorosilane.

[0114] (2) Preparation of long-chain alkane-based modified hydroxyl-terminated silicone oil

[0115] After mixing 1 part of tetradecanemethyldichlorosilane and 3 parts of dimethyldichlorosilane uniformly prepared in the above steps, they were added dropwise to the dichloromethane suspension...

Embodiment 2

[0120] Embodiment 2 long-chain alkane group and vinyl modified ultrahigh molecular weight polysiloxane

[0121] (1) Preparation of long-chain alkane-based and vinyl-modified hydroxyl-terminated silicone oils

[0122] Repeat the step (1) of Example 1, and after mixing 1 part of tetradecanemethyldichlorosilane, 3 parts of dimethyldichlorosilane and 1 part of methylvinyldichlorosilane, dropwise add In the dichloromethane suspension containing 5 parts of sodium bicarbonate, the temperature is kept at 30°C. After the hydrochloric acid is removed, the hydrolysis reaction is completed, and the sodium chloride and unreacted sodium bicarbonate are removed by filtration, and the dichloromethane is recovered to obtain ten Tetraalkane- and vinyl-modified hydroxyl-terminated silicone oil with a viscosity of 80cSt / 25°C and a yield of 75%.

[0123] (2) Preparation of long-chain alkane-based, vinyl-modified ultra-high molecular weight polysiloxane

[0124] Mix 1 part of tetradecane-based an...

Embodiment 3

[0125] Example 3 Long-chain alkane group, long-chain fluorocarbon group, vinyl modified ultra-high molecular weight polysiloxane

[0126] (1) Preparation of long-chain fluorocarbon-based modified silane

[0127] Add perfluorohexylethylene dropwise to the toluene mixed solution of methyldichlorosilane and platinum catalyst. The platinum catalyst is a Speier catalyst. Calculated by platinum atomic mass, the amount of catalyst used is 1 / 10,000 of the total mass of reactants. Perfluorohexylethylene The molar ratio to methyldichlorosilane was 1.1:1, the reaction temperature was 80°C, and the reaction was carried out for 5 hours. After the reaction, unreacted raw materials and solvents were evaporated to obtain perfluorohexylmethyldichlorosilane.

[0128] (2) Preparation of long-chain alkane group, long-chain fluorovinyl modified hydroxyl-terminated silicone oil

[0129] Step (1) of Example 1 was repeated, and 1 part of tetradecylmethyldichlorosilane, 1 part of perfluorohexylmethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Z-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com