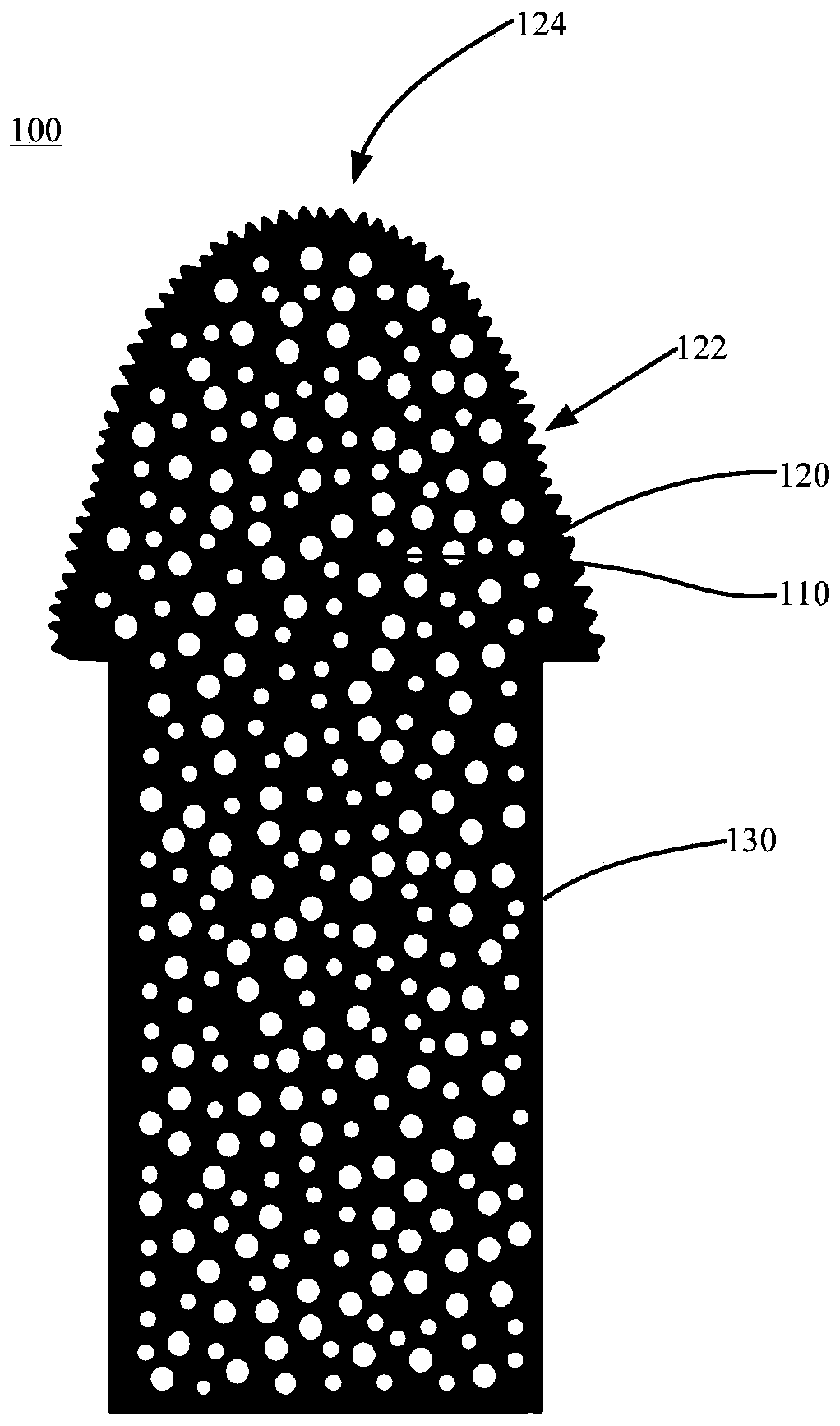

Composite material for touch pen nib, pen nib and preparation method

A composite material, stylus technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of large screen impact sound, increase user fatigue, screen damage, etc. The effect of touch and screen protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

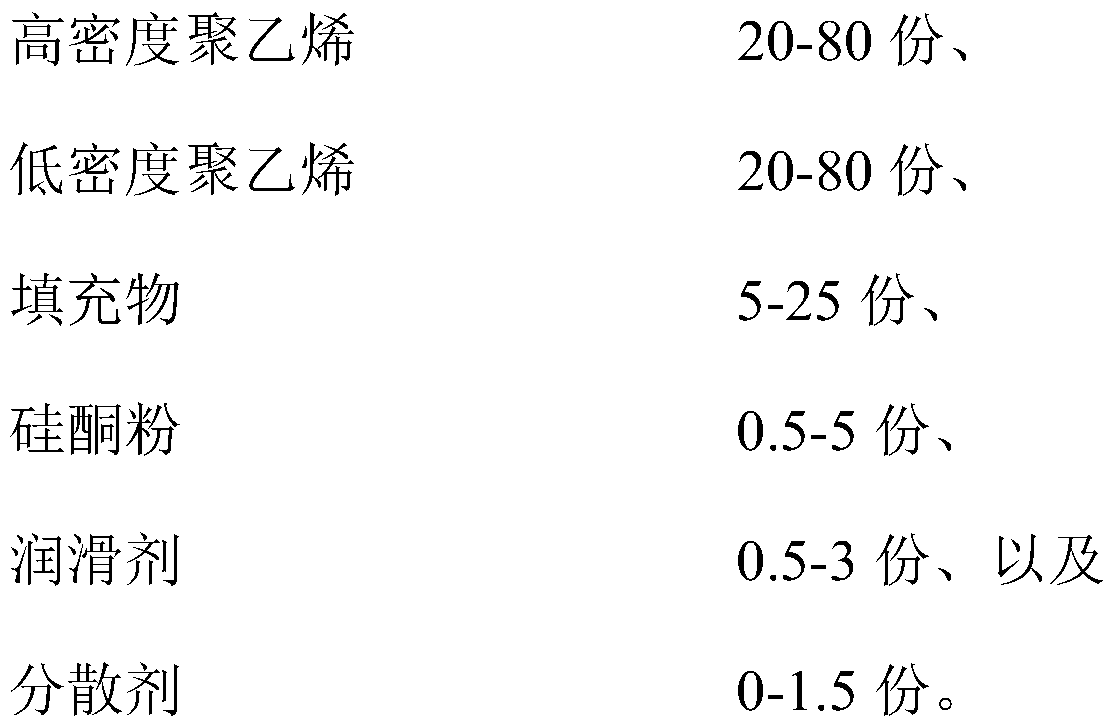

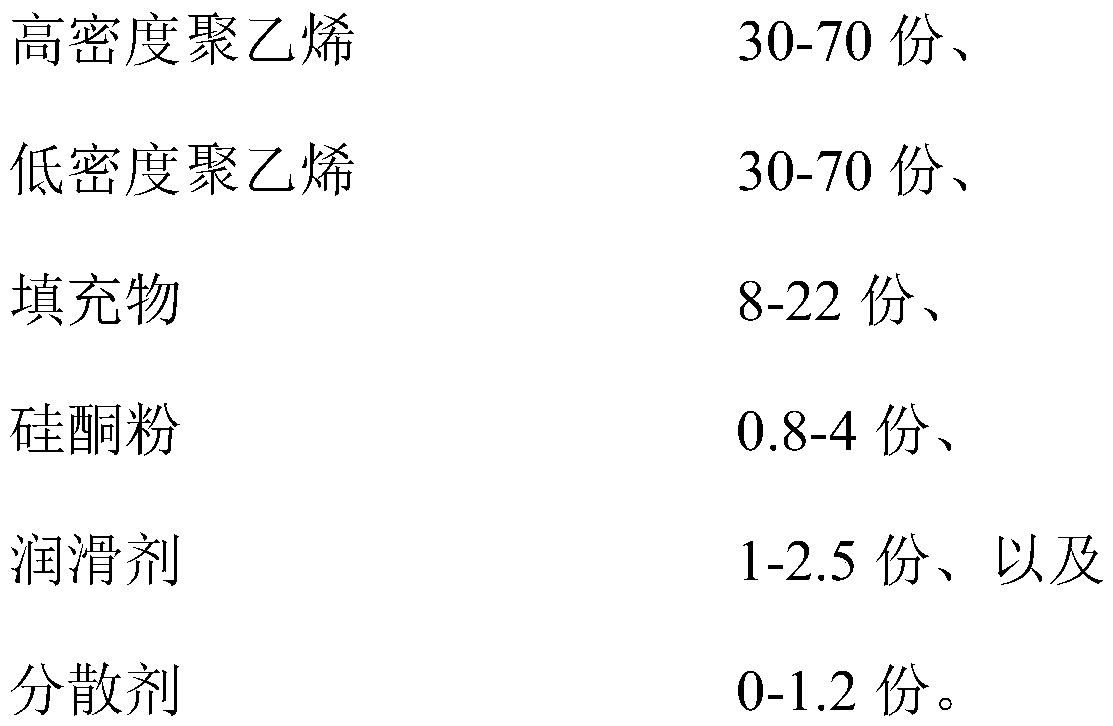

[0040] The present invention also provides a method for preparing a composite material for the tip of a stylus pen, comprising the steps of:

[0041] Mix 20-80 parts of high-density polyethylene, 20-80 parts of low-density polyethylene, 5-25 parts of filler, 0.5-5 parts of silicone powder, 0.5-3 parts of lubricant and 0.5-1.5 parts The dispersant is mixed evenly and discharged;

[0042] The homogeneously mixed material is melted and granulated to obtain a composite material for a stylus pen tip.

[0043] In a specific example, the method for preparing the composite material for the tip of the stylus further includes a step of drying high-density polyethylene and / or low-density polyethylene, for example, drying at 60°C-90°C for 2h- 6h.

[0044] The uniform mixing is preferably carried out at a high speed of 1 minute to 3 minutes at a speed of 3000rpm-5000rpm, and then stirred at a low speed of 500rpm-2000rpm for 1 minute to 3 minutes, and finally discharged at a speed of 500r...

Embodiment 1

[0059] Embodiment 1 provides a composite material for the nib of an infrared stylus pen, which includes the following raw materials in parts by weight: 50 parts of high-density polyethylene, 50 parts of low-density polyethylene, 20 parts of filler, 2 parts of silicone powder, 1 part of lubricant and 0.5 part of dispersant. Wherein, the heat distortion temperature of the high-density polyethylene is 75°C, and the melt index is 1.3g / 10min; the heat distortion temperature of the low-density polyethylene is 45°C, and the melt index is 2g / 10min; the lubricant is Ethylene bis stearamide (EBS), the particle size is 35 μm; the filler is mica powder with a particle size of 0.05 mm; the silicone powder particle size is 10 μm.

[0060] The preparation method of the composite material for the nib of the infrared stylus comprises the following steps:

[0061] (1) Dry the high-density polyethylene and low-density polyethylene with the above-mentioned specific physical properties at 80°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com