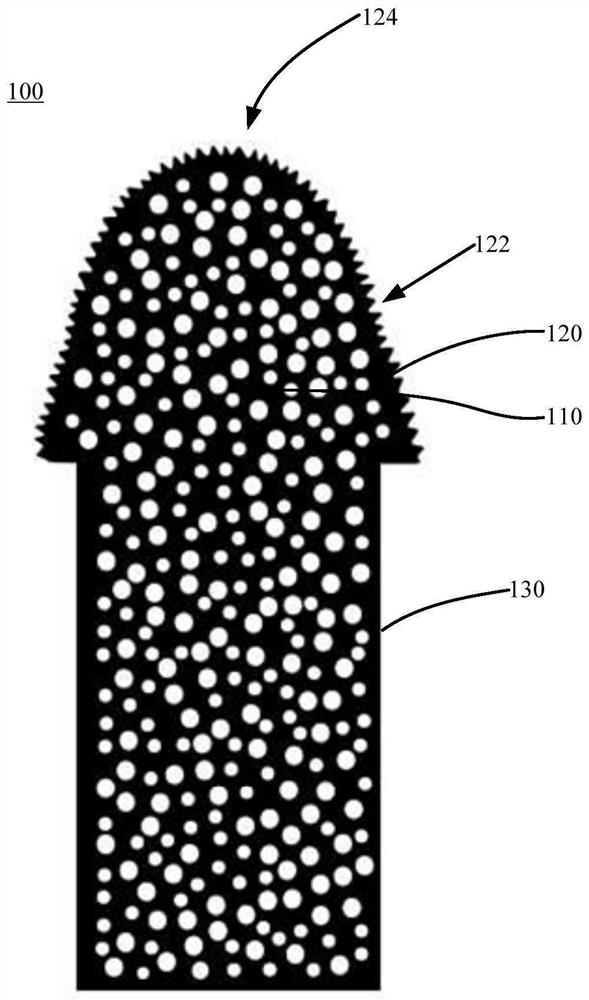

Composite material for stylus tip, tip and preparation method

A technology of composite materials and stylus, which is applied in the field of pen tip and preparation, composite material for stylus pen tip, can solve the problems that it is difficult to pass the wear resistance and drop test of the pen tip, increase user fatigue, and unfavorable writing input accuracy, etc. Achieve the effects of increasing interface compatibility, increasing surface roughness, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a composite material for the tip of a stylus pen, comprising the steps of:

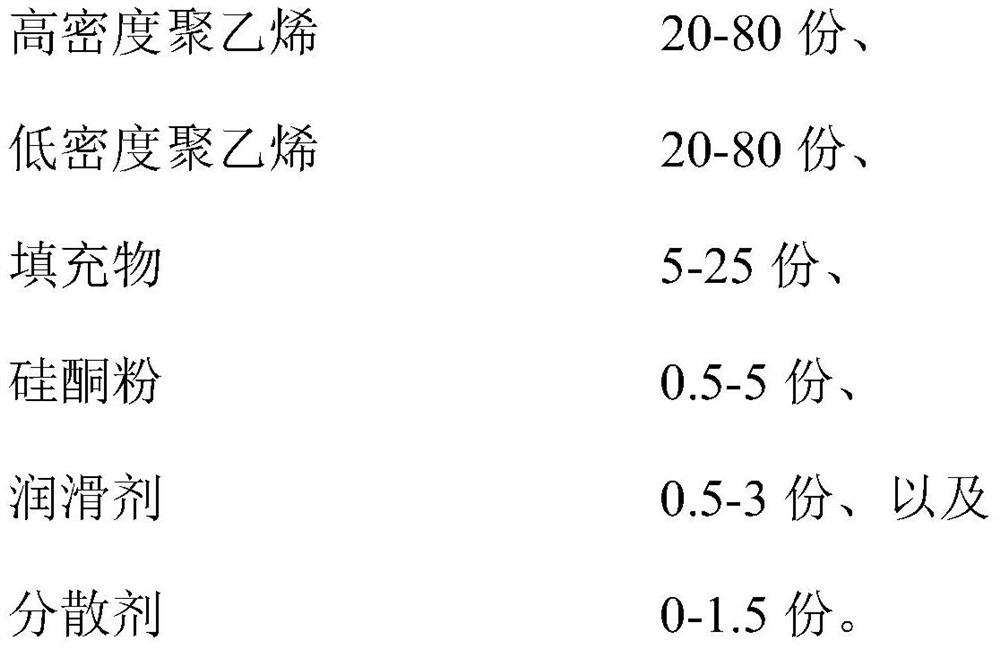

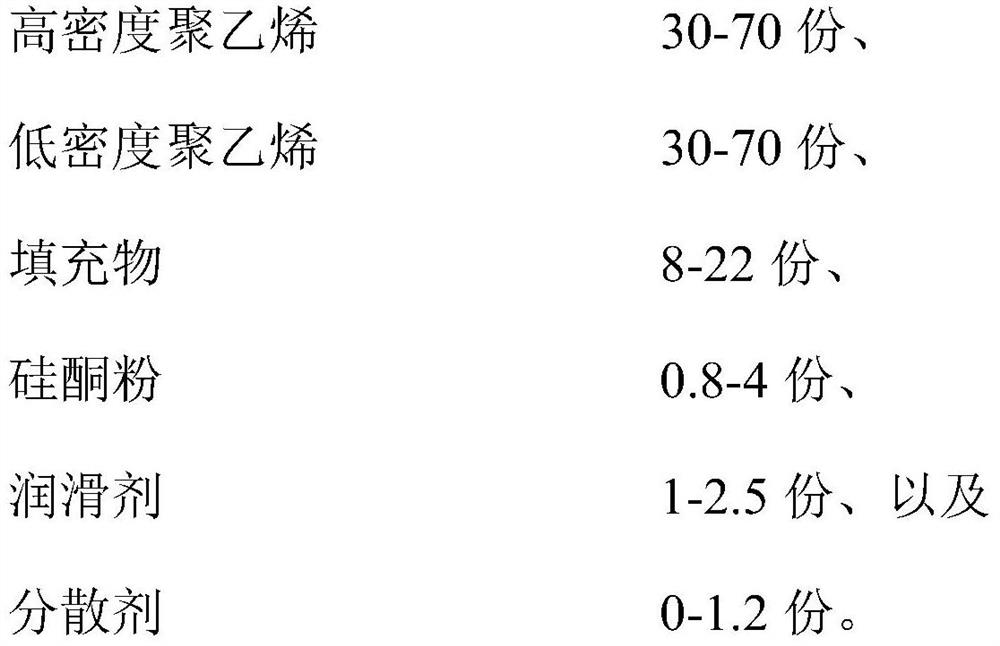

[0041] Mix 20-80 parts of high-density polyethylene, 20-80 parts of low-density polyethylene, 5-25 parts of filler, 0.5-5 parts of silicone powder, 0.5-3 parts of lubricant and 0.5-1.5 parts The dispersant is mixed evenly and discharged;

[0042] The homogeneously mixed material is melted and granulated to obtain a composite material for a stylus pen tip.

[0043] In a specific example, the method for preparing the composite material for the tip of the stylus further includes a step of drying high-density polyethylene and / or low-density polyethylene, for example, drying at 60°C-90°C for 2h- 6h.

[0044] The uniform mixing is preferably carried out at a high speed of 1 minute to 3 minutes at a speed of 3000rpm-5000rpm, and then stirred at a low speed of 500rpm-2000rpm for 1 minute to 3 minutes, and finally discharged at a speed of 500r...

Embodiment 1

[0059] Embodiment 1 provides a composite material for the nib of an infrared stylus pen, which includes the following raw materials in parts by weight: 50 parts of high-density polyethylene, 50 parts of low-density polyethylene, 20 parts of filler, 2 parts of silicone powder, 1 part of lubricant and 0.5 part of dispersant. Wherein, the heat distortion temperature of the high-density polyethylene is 75°C, and the melt index is 1.3g / 10min; the heat distortion temperature of the low-density polyethylene is 45°C, and the melt index is 2g / 10min; the lubricant is Ethylene bis stearamide (EBS), the particle size is 35 μm; the filler is mica powder with a particle size of 0.05 mm; the silicone powder particle size is 10 μm.

[0060] The preparation method of the composite material for the nib of the infrared stylus comprises the following steps:

[0061] (1) Dry the high-density polyethylene and low-density polyethylene with the above-mentioned specific physical properties at 80°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com