A self-excited pump driven by two oscillators

A dual vibrator and vibrator technology, applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve the problem of low output flow and pressure accuracy, poor flatness and cut-off effect, pump output flow and pressure drop, etc. problem, to achieve the effect of improving output capability and control accuracy, good cut-off effect, and high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

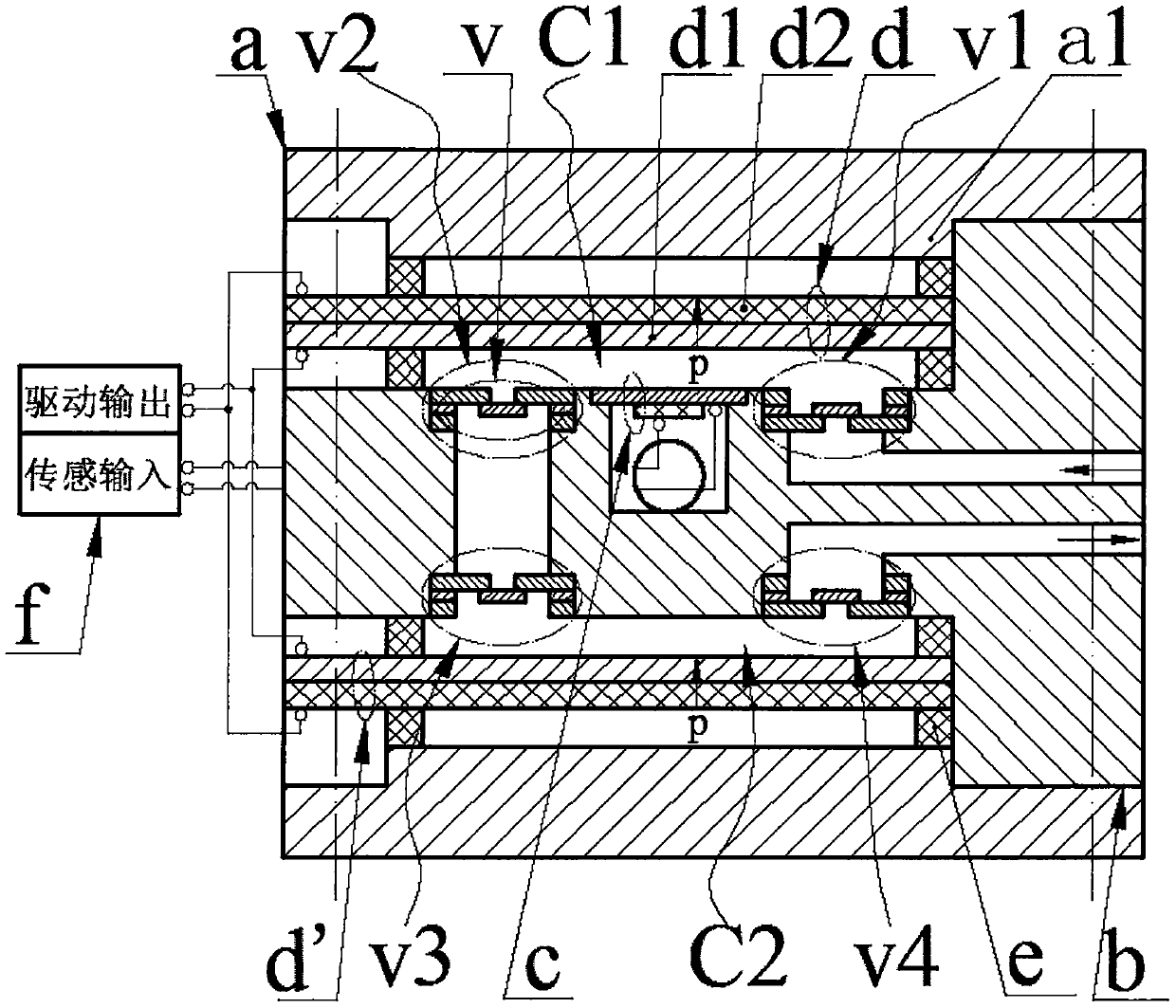

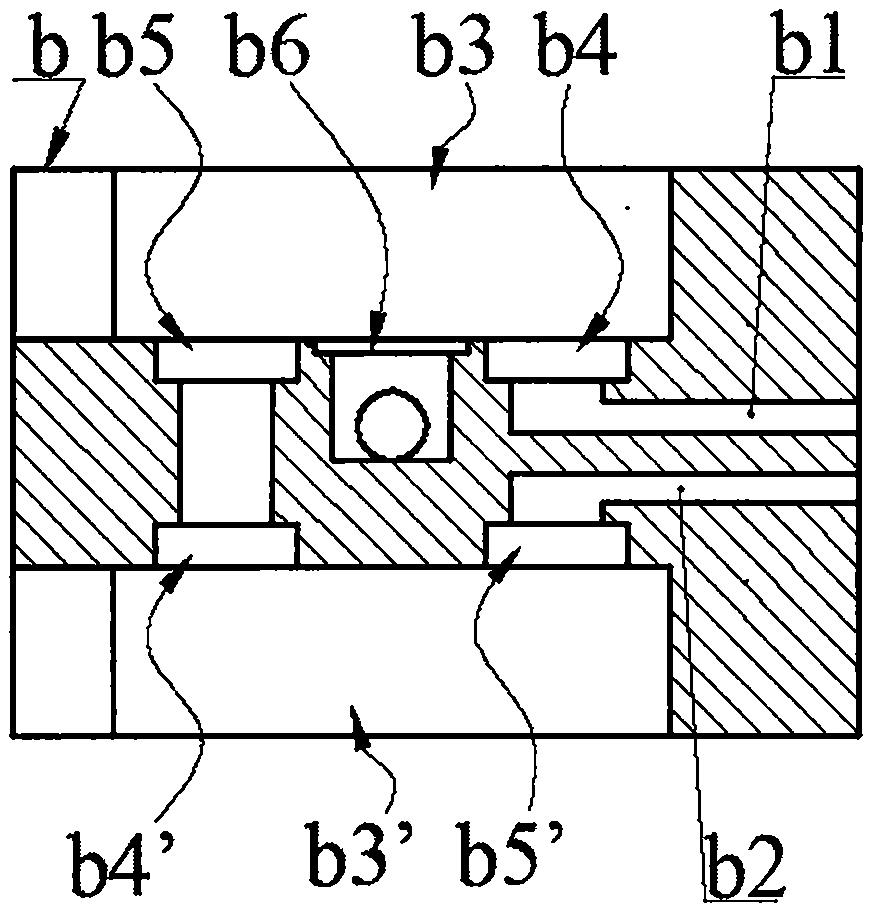

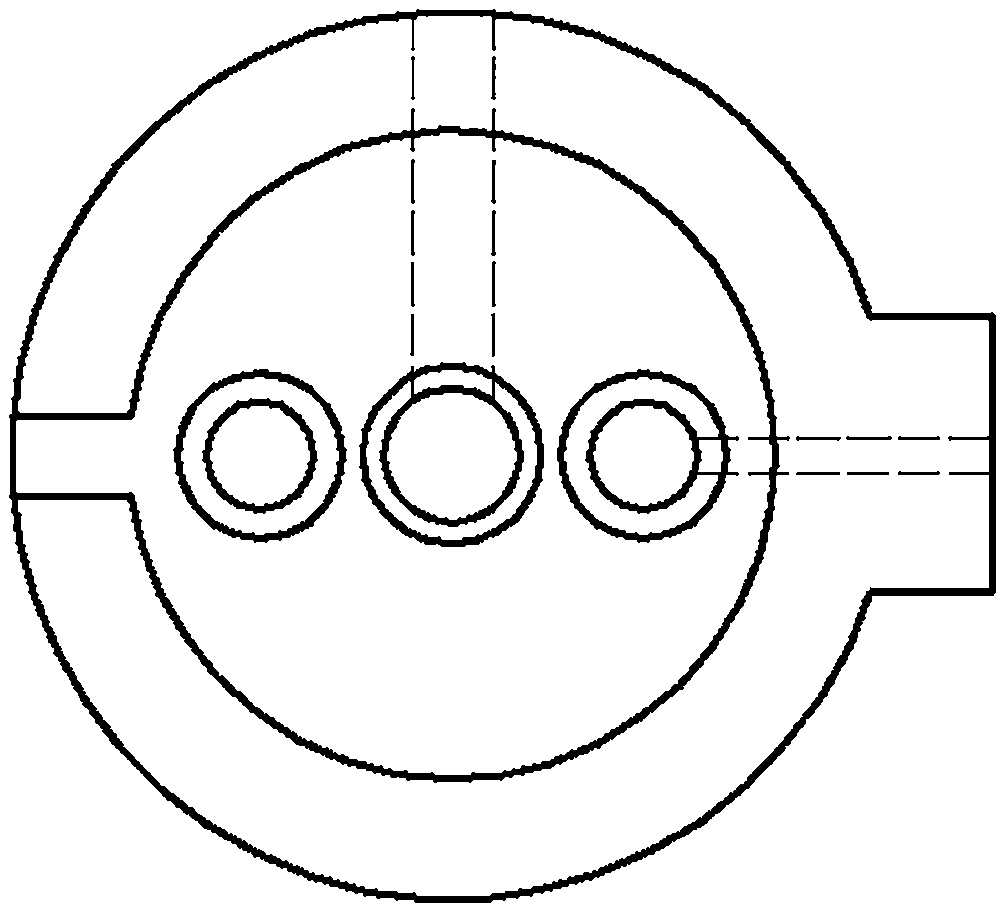

[0017] A self-excited pump driven by double oscillators of the present invention is composed of pump cover a, pump body b, disc valve v, sensor c, upper chamber oscillator d, lower chamber oscillator d', sealing ring e, power supply f and wire group . The pump body b is provided with an inlet b1, an outlet b2, an upper body cavity b3 and a lower body cavity b3', the bottom wall of the upper body cavity b3 is provided with an upper inlet valve cavity b4 and an upper outlet valve cavity b5, and the top wall of the lower body cavity b3' The lower inlet valve cavity b4' and the lower outlet valve cavity b5' are provided, the side walls of the upper body cavity b3 and the lower body cavity b3' are provided with wiring grooves, the bottom wall of the upper body cavity b3 or the top wall of the lower body cavity b3' There is a sensor chamber b6 on the top, and a wiring hole is provided on the side wall of the sensor chamber b6; the upper inlet valve chamber b4 communicates with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com