Detection method of surface strain and displacement of marine anticorrosive coating

A detection method and marine anti-corrosion technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as direct strain and displacement measurement, and achieve the effect of great practical significance, wide application range and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

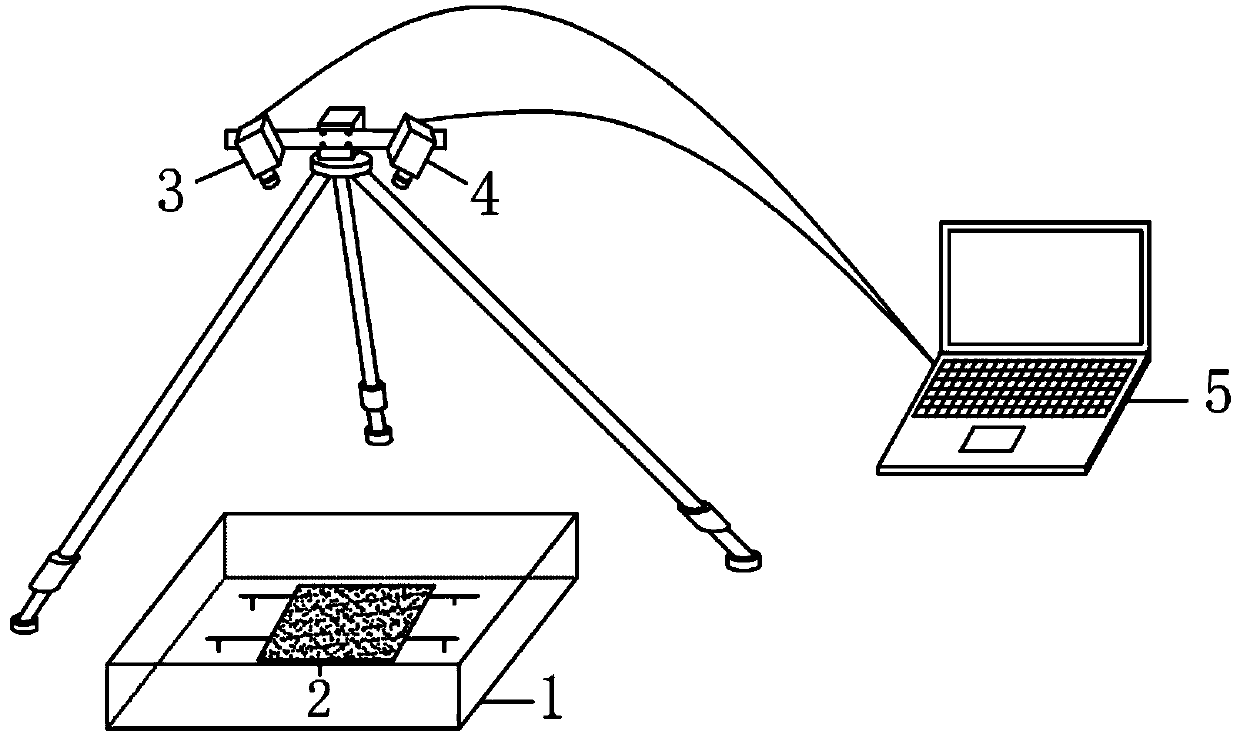

[0031] In conjunction with the figure, the present invention includes the following steps:

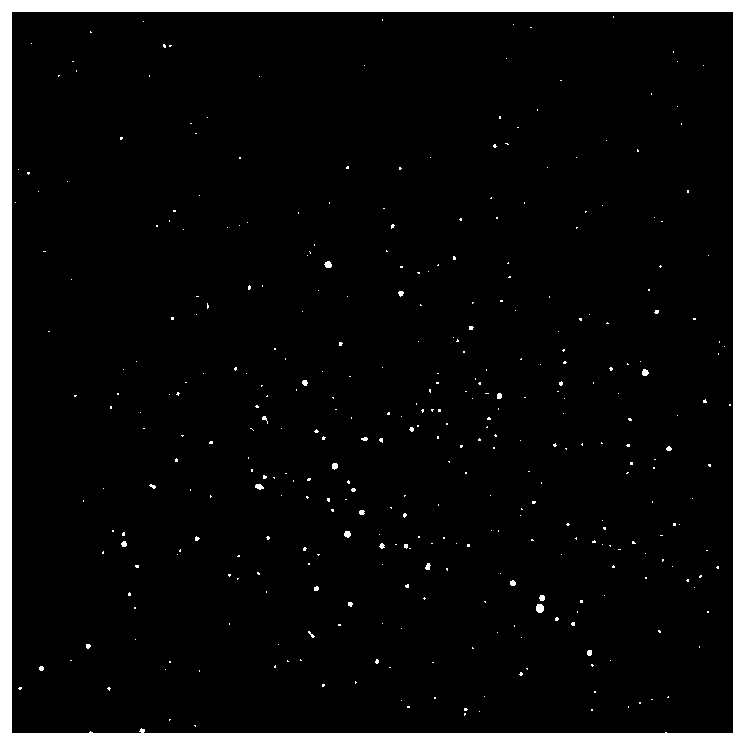

[0032] Step 1: Apply artificial speckle marks on the surface of the test piece in advance: first spray black matte paint on the surface of the test piece as a background, then spray white matte paint on the surface of the test piece in granular form, and as much as possible Make the particle distribution random, and fix the test piece horizontally in the seawater corrosion device;

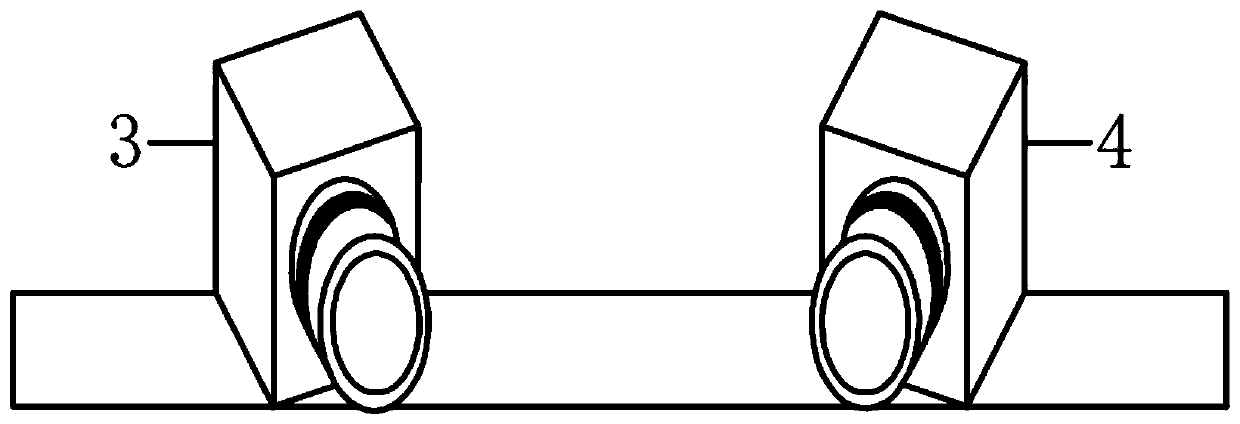

[0033] Step 2: Arrange two left and right industrial digital cameras at equal distances directly above the test piece. The angles between the two cameras and the test piece are the same, and the optical axes of the two cameras intersect at the center of the test piece. By adjusting the camera’s aperture and focal length , to ensure that the image of the speckle pattern on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com