Bus-based high-integration automobile LED headlight controller

A high-integration, controller technology, applied in the use of semiconductor lamps, electrical components, electroluminescent light sources, etc., can solve problems such as insufficient fault diagnosis ability, over-position failure, heavy weight, etc., to reduce the burning of wire harnesses. possibility, reduce the weight of the whole vehicle, save the effect of wiring harness layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

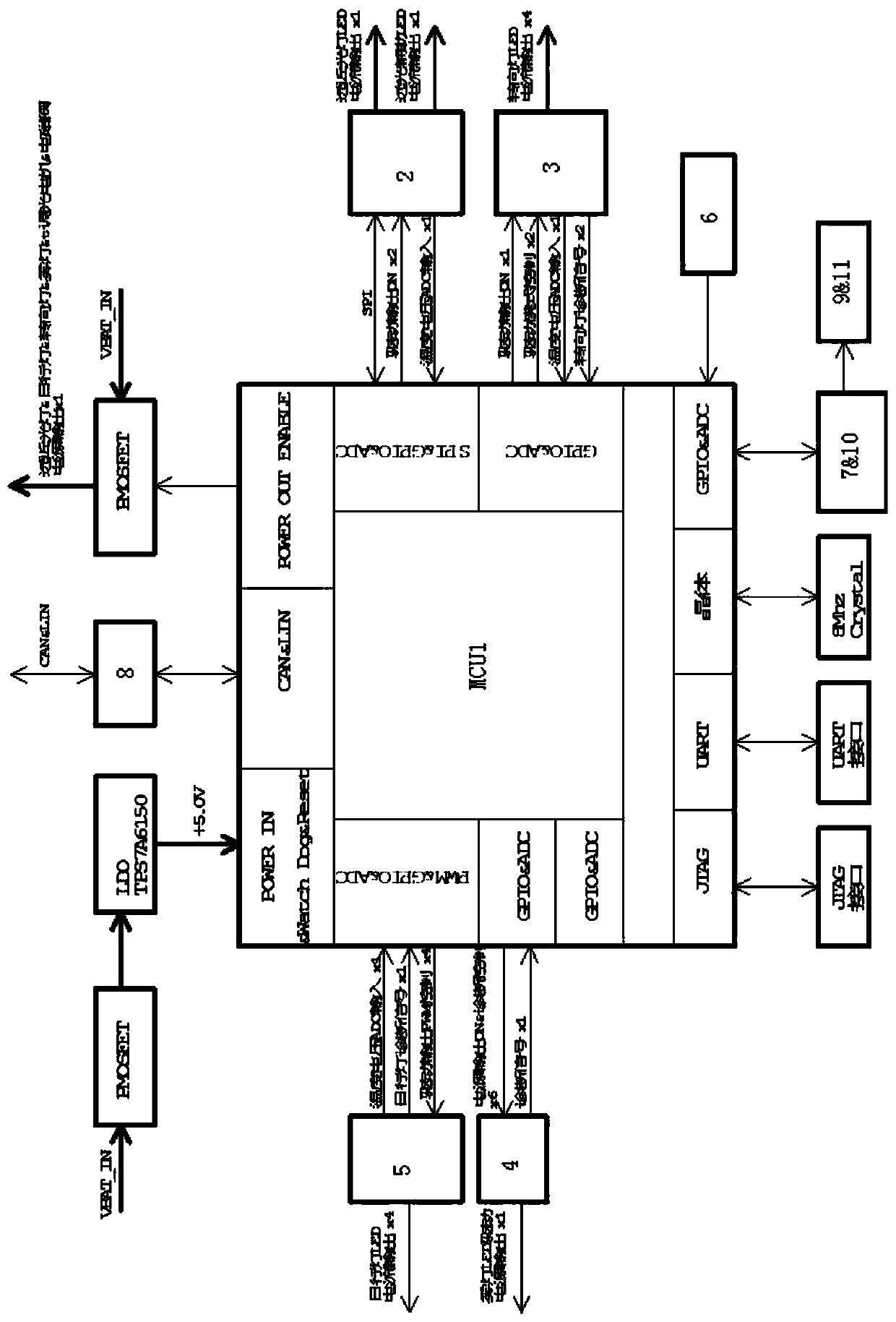

[0027] In this embodiment, a bus-based highly integrated automotive LED headlight controller, such as figure 1 As shown, it includes MCU1, far and near light drive circuit 2, turn signal LED drive circuit 3, fog light LED drive circuit 4, daytime running light / position light LED drive circuit 5, temperature sampling circuit 6, headlight height adjustment dimming motor control circuit 7 and transceiver 8, the MCU communicates with the upper system through the transceiver, far and near light drive circuit, turn signal LED drive circuit, fog light LED drive circuit, daytime running light / position light LED drive circuit, temperature sampling circuit, headlight height adjustment The dimming motor control circuit is respectively connected with the MCU. The MCU communicates with the upper system through the CAN bus, and the transceiver model is TJA1042T.

[0028] The MCU controls the constant current drive chip of the far and near light drive circuit through the SPI interface. The ...

Embodiment 2

[0035] This embodiment is a bus-based highly integrated automotive LED headlight controller. Compared with Embodiment 1, the MCU in this embodiment communicates with the upper-level system through the LIN bus, and the transceiver model used is TJA1020T.

Embodiment 3

[0037] This embodiment is a bus-based highly integrated automotive LED headlight controller. Compared with Embodiment 1, the headlight height adjustment and dimming motor control circuit in this embodiment is different.

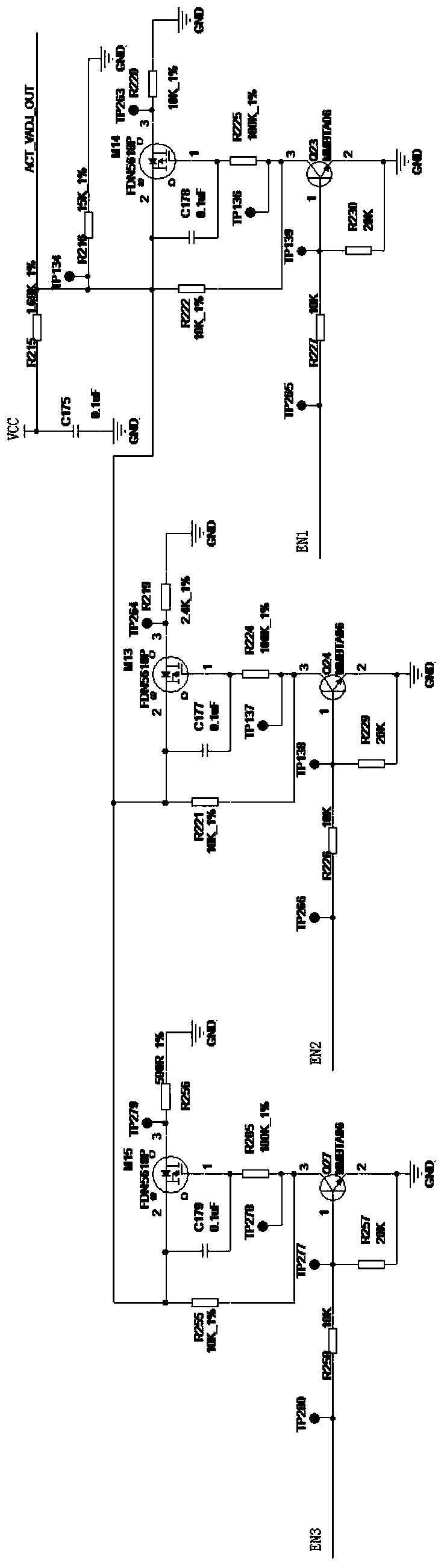

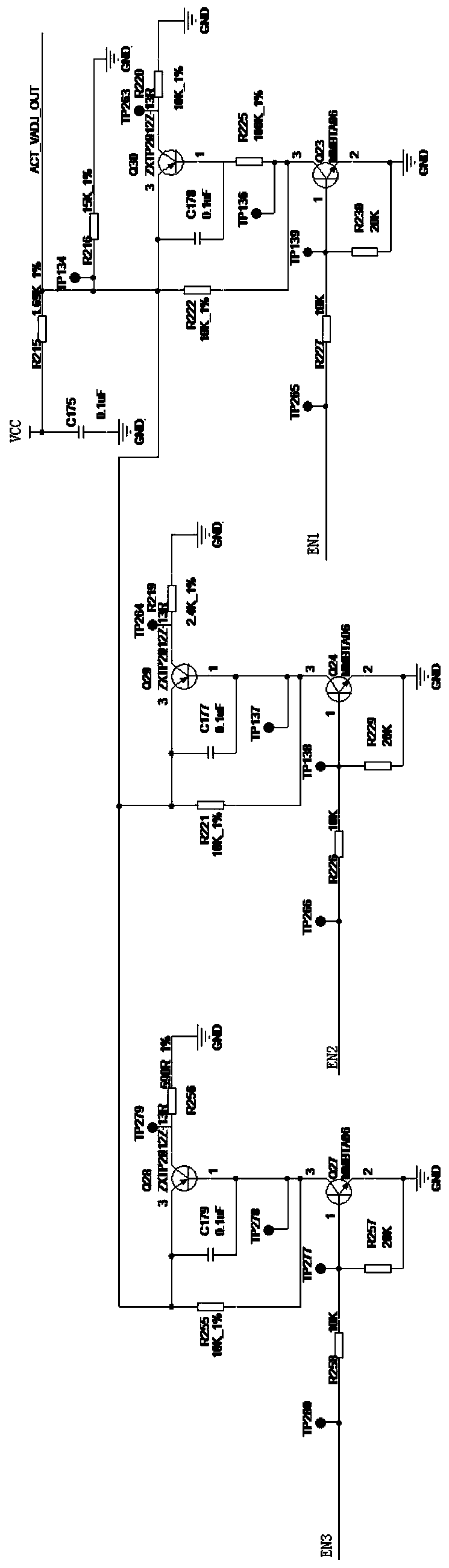

[0038] Such as image 3 As shown, the headlight height adjustment dimming motor control circuit includes a voltage output circuit and a multi-channel voltage divider circuit. The voltage output circuit includes resistors R215, R216 and a capacitor C175. The first terminal of the capacitor C175 is connected to the power supply VCC , the second end of the capacitor C175 is grounded to GND, the first end of the resistor R215 is connected to the power supply VCC, the second end is respectively connected to the headlight height adjustment dimming motor, the first end of the resistor R216 and all voltage dividing circuits, the second end of the resistor R216 Ground GND. The voltage divider circuit includes resistors R255, R256, R257, R258, capacitor C179, transist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com