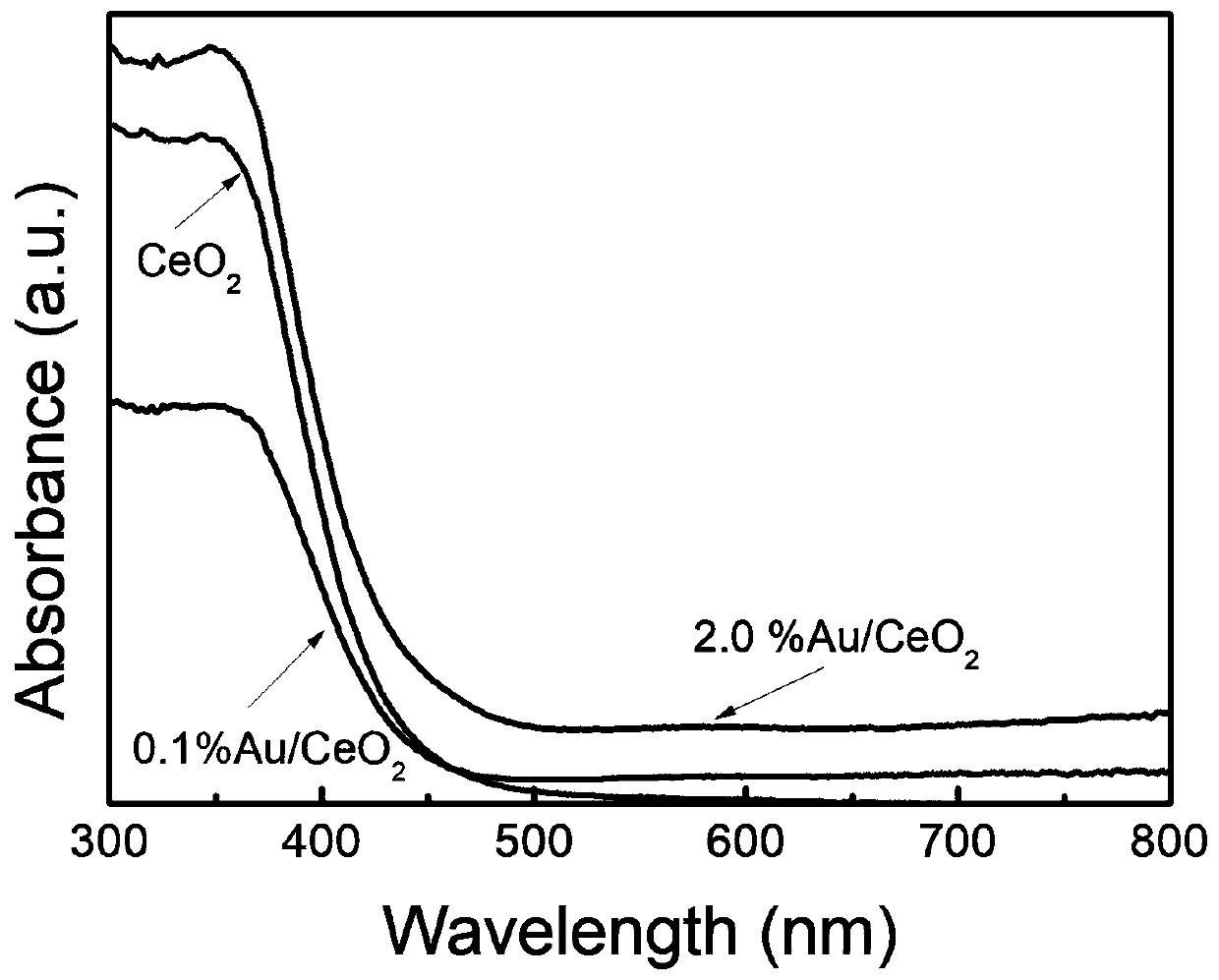

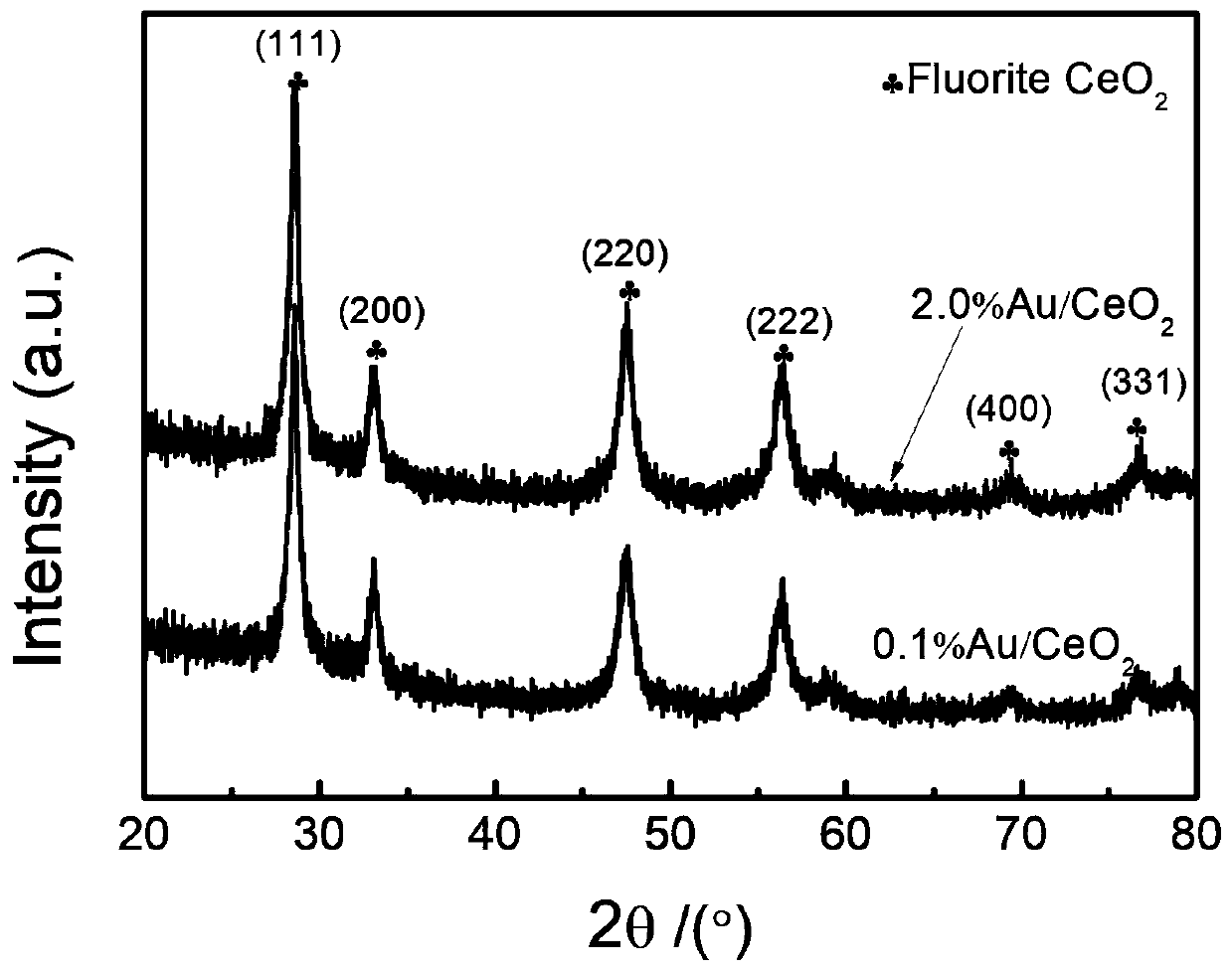

Preparation method of monoatomic Au modified CeO2 catalyst for degrading formaldehyde at low temperature

A catalyst and atom technology, which is applied in the field of preparation of single-atom Au-modified CeO2 catalyst for degrading formaldehyde at low temperature, can solve the problem of high efficiency degradation of formaldehyde, and achieve excellent catalytic degradation performance and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A monoatomic Au modified CeO for degradation of formaldehyde at low temperature 2 (Au / CeO 2 ) The preparation method of the catalyst includes the following steps:

[0034] Step 1: Weigh 1g of mesoporous CeO 2 Stir the powder in 30ml deionized water evenly to obtain mesoporous CeO 2 Aqueous solution

[0035] Step 2: Configure HAuCl with a concentration of 0.0024mol / L 4 Aqueous solution, as the Au precursor solution;

[0036] Step 3. Use a 20ml syringe to suck up the appropriate amount of HAuCl configured in Step 2. 4 Aqueous solution, and install the syringe on the micro-injection pump, connect the pipeline interface; among them, set the working parameters of the micro-injection pump: injection rate 0.02ml / min, injection time 50min, which is the injected HAuCl 4 The total amount of solution is 1ml;

[0037] Then, under magnetic stirring (300r / min), the Au precursor solution was slowly injected into the uniform mesoporous CeO 2 In the aqueous solution, magnetically stir for 3 hour...

Embodiment 2

[0040] A monoatomic Au modified CeO for degradation of formaldehyde at low temperature 2 (Au / CeO 2 ) The preparation method of the catalyst includes the following steps:

[0041] Step 1: Weigh 1g of mesoporous CeO 2 Stir the powder in 30ml deionized water evenly to obtain mesoporous CeO 2 Aqueous solution

[0042] Step 2: Configure HAuCl with a concentration of 0.024mol / L 4 Aqueous solution, as the Au precursor solution;

[0043] Step 3. Use a 20ml syringe to suck up the appropriate amount of HAuCl configured in Step 2. 4 Aqueous solution, and install the syringe on the micro-injection pump, connect the pipeline interface; among them, set the working parameters of the micro-injection pump: injection rate 0.02ml / min, injection time 10min, that is the injected HAuCl 4 The total amount of solution is 0.2ml;

[0044] Then, the Au precursor solution was slowly injected into the uniform mesoporous CeO under magnetic stirring (400r / min) 2 In the aqueous solution, magnetically stir for 2 hours...

Embodiment 3

[0047] A monoatomic Au modified CeO for degradation of formaldehyde at low temperature 2 (Au / CeO 2 ) The preparation method of the catalyst includes the following steps:

[0048] Step 1: Weigh 1g of mesoporous CeO 2 Stir the powder in 30ml deionized water evenly to obtain mesoporous CeO 2 Aqueous solution

[0049] Step 2: Configure HAuCl with a concentration of 0.024mol / L 4 Aqueous solution, as the Au precursor solution;

[0050] Step 3. Use a 10ml syringe to suck up the appropriate amount of HAuCl configured in Step 2. 4 Aqueous solution, and install the syringe on the micro-injection pump, connect the pipeline interface; among them, set the working parameters of the micro-injection pump: injection rate 0.1ml / min, injection time 10min, that is the injected HAuCl 4 The total amount of solution is 1ml;

[0051] Then, under magnetic stirring (500r / min), the Au precursor solution was slowly injected into the uniform mesoporous CeO 2 In the aqueous solution, magnetically stir for 1 hour to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com