Cleaning and drying device for small metal part

A drying device and small parts technology, applied in the field of hardware, can solve the problems that the production of hardware parts is not necessarily clean and pollution-free, rough manual cleaning of hardware parts, low efficiency, etc., so as to save economic expenses, improve full utilization rate and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

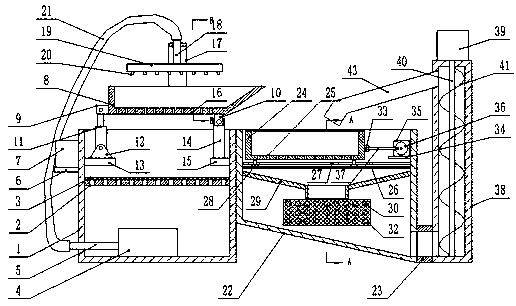

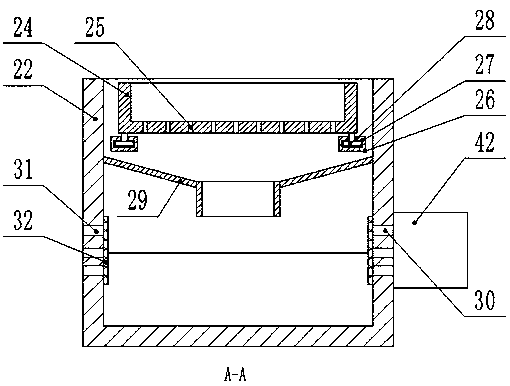

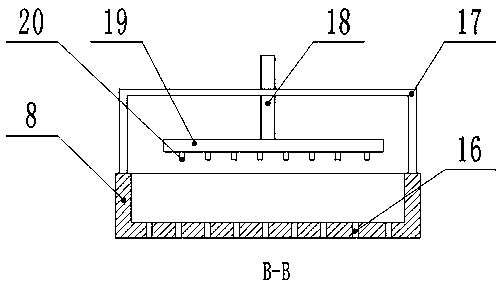

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a small hardware cleaning and drying device includes a cleaning box 1, and an orifice plate 2 is fixed horizontally in the center of the interior of the cleaning box 1, and a filter screen 3 is fixedly attached to the top surface of the orifice plate 2. The lower end of the orifice plate 2 is provided with a submersible pump 4, and the water outlet of the submersible pump 4 is fixedly connected with a water outlet pipe 5, and the other end of the water outlet pipe 5 penetrates the side wall of the cleaning box 1 and stretches out of the cleaning box 1. A fixed plate 6 is fixed on one side of the cleaning box 1, and a hydraulic station 7 is fixedly placed on the fixed plate 6. A washing tank 8 is provided at the upper end of the cleaning box 1, and several through-holes are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com