A silicon wafer edge polishing process

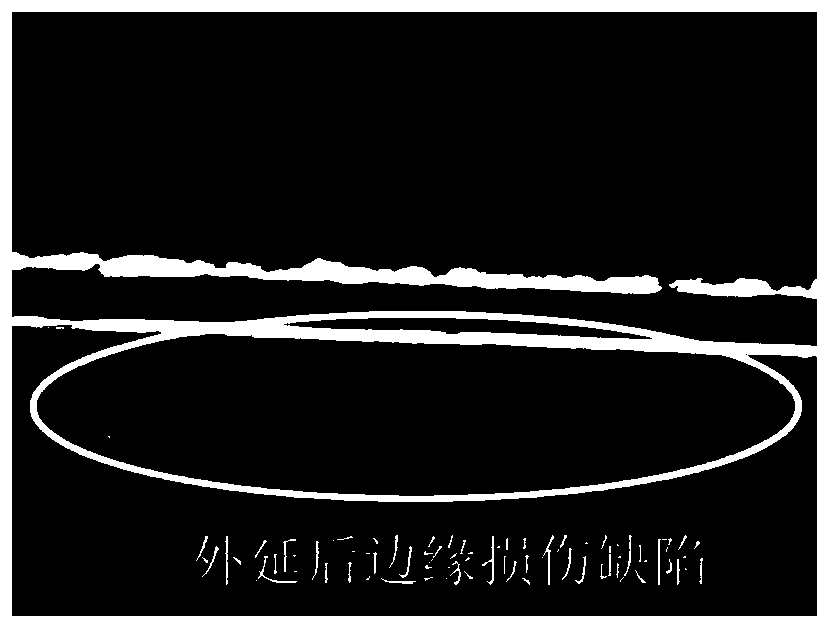

A silicon wafer and edge technology, which is applied in the field of silicon wafer edge polishing technology, can solve problems such as corrosion damage on the reference surface of silicon wafers, and achieve the effect of solving corrosion damage and improving device processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Processing of 8-inch silicon wafers with heavy As doping and a 22-degree chamfer angle

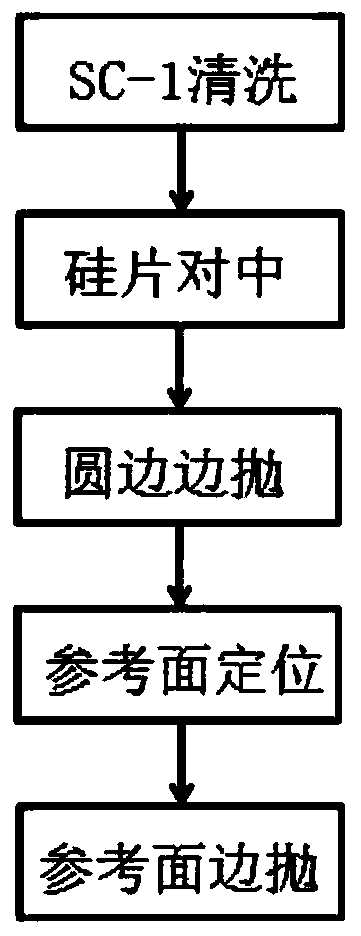

[0027] (1) Use a cleaning machine to clean the silicon wafers to be edge-thinned, and first clean them with SC-1. The SC-1 cleaning solution is composed of ammonia water, hydrogen peroxide and pure water in a ratio of 1:1:15. The cleaning time was 7 minutes, and the cleaning temperature was 70° C., and then the QDR was rinsed 3 times in a pure water tank. Finally, use the spin drying method to dry.

[0028] (2) Put the silicon wafer cleaned in step (1) into the loading table of the side throwing machine, and transport it to the centering machine by the robot for centering and positioning, ensuring that the deviation between the center of the silicon wafer and the center of the machine is within 0.2mm.

[0029] (3) Step (2) is completed to carry out round edge polishing process on the silicon wafer in the middle, the polishing cloth hardness used is 60Aske-C, and the edge polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com