Production method of high purity cobalt

A high-purity, cobalt-salt technology, which is applied in photographic technology, instruments, and photographic auxiliary processes, can solve problems such as electrolyte pollution, high energy consumption, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

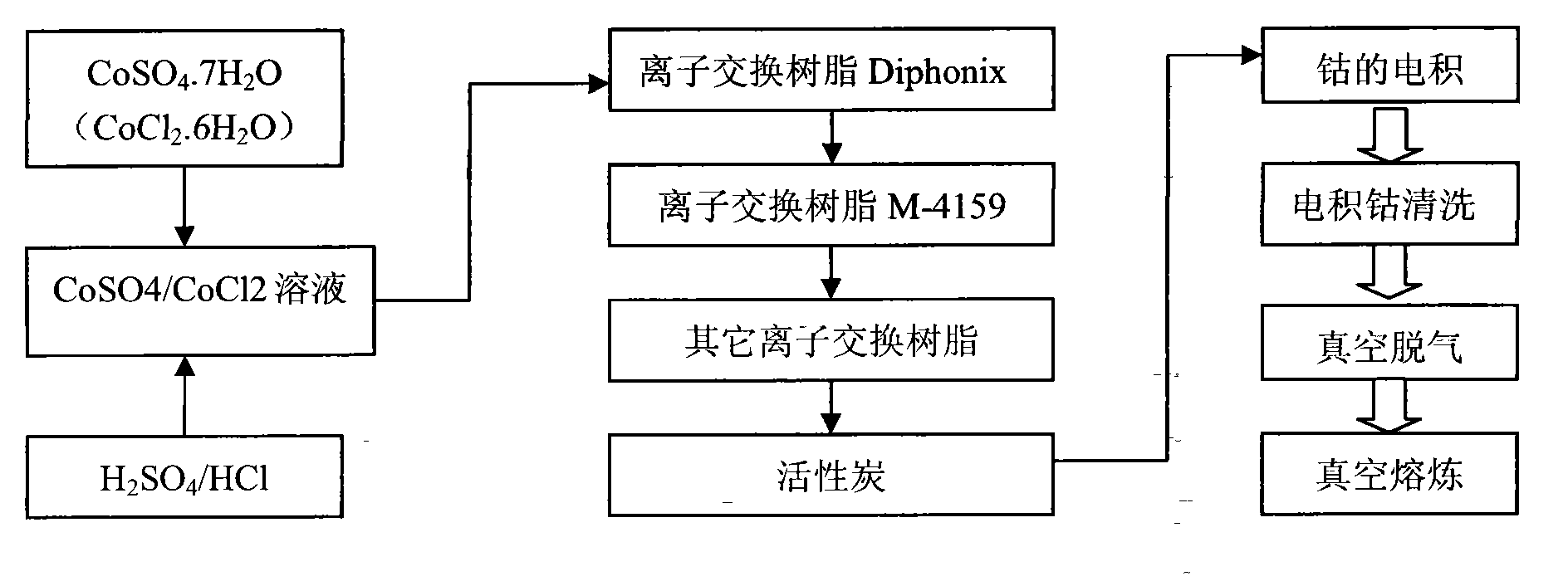

[0011] The production process steps of high-purity cobalt of the present invention are as follows:

[0012] (1) Preparation of cobalt salt solution. (1a) Prepare a certain volume of CoSO with a target cobalt concentration of 60-100g / L 4 solution, calculate the required high-purity cobalt sulfate CoSO 4 .7H 2 The relative proportion of O and deionized water, the resulting weight of high-purity cobalt sulfate CoSO 4 .7H 2 O and deionized water were placed in a container and stirred at room temperature until CoSO 4 .7H 2 O is completely dissolved. Then add sulfuric acid H 2 SO 4 Adjust the pH of the cobalt salt solution to 1-3. Or (1b) prepare a certain volume, the target cobalt concentration is 60 ~ 100g / L, CoSO 4 and CoCl 2 A certain percentage of CoSO 4 and CoCl 2 Mix the solution and calculate the required high-purity cobalt sulfate CoSO 4 .7H 2 O, high-purity cobalt hydrochloride CoCl 2 .6H 2 O, and the relative ratio of deionized water, the high-purity coba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com