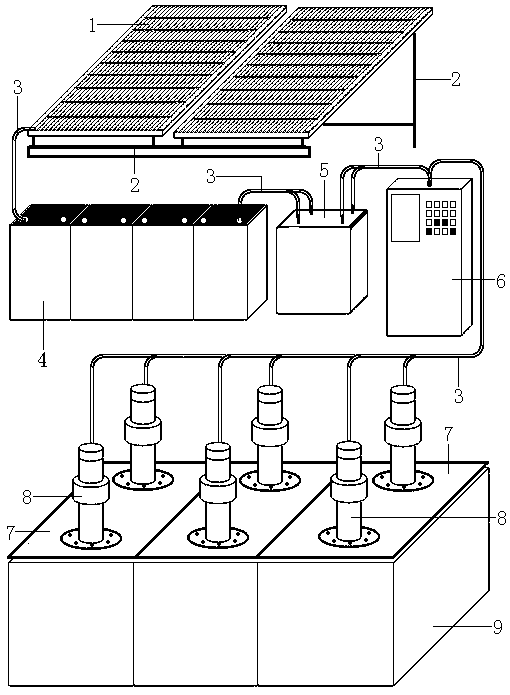

Hydrolyzate fermentation utilizing solar energy stirring technology

A solar energy and hydrolyzate technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, energy industry, etc., can solve the problem of power consumption, effective space and unutilized sunlight resources, increase cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

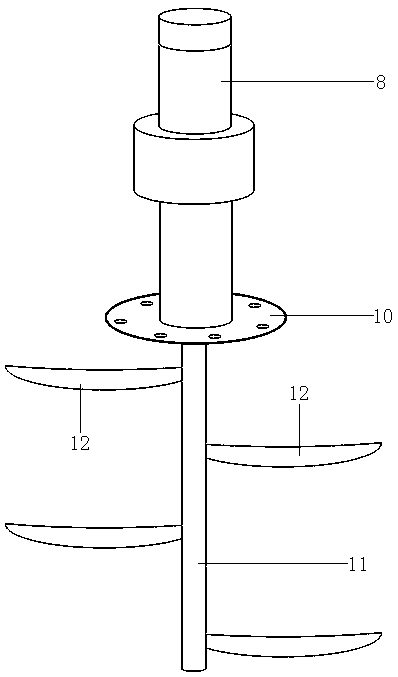

[0017] According to the above-mentioned hydrolyzate fermentation using solar energy mixing technology in use, the crushed turmeric paste is added with dilute sulfuric acid and then put into the fermentation tank for fermentation. The industrial power supply passes through the intelligent control box to drive each group of stirring motors to stir the turmeric paste in a time-sharing cycle. After eight o'clock, the sunlight gradually becomes stronger, and the monocrystalline silicon array panels begin to generate electricity under the sunlight. The current generated by multiple monocrystalline silicon array panels is either connected in parallel or in series, and then sent to the battery pack through the power line, and the battery pack transfers the current to the battery pack. After temporary storage, it is sent to the electronic inverter through the power line. The inverter converts the DC current into AC current and then boosts it to industrial voltage, and then sends it to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap