Preparation process of multifunctional algae fiber fabrics

A technology of seaweed fiber and preparation process, applied in the field of textile materials, can solve the problems of large influence of dyeing process, reduced antibacterial properties of seaweed fiber, single function of seaweed fiber fabric, etc., and achieves the effect of uniform dyeing and easier dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

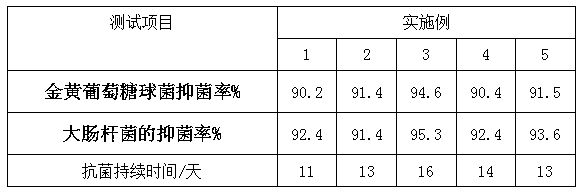

Examples

Embodiment 1

[0018] The preparation technology of a kind of multifunctional seaweed fiber fabric that the present invention proposes, comprises the following steps:

[0019] S1. Preparation of treatment solution: In parts by weight, weigh 1 part of sodium bis(2-ethylhexyl) sulfosuccinate, 0.3 part of polyoxyethylene fatty alcohol ether, 3 parts of carboxymethyl chitosan, 0.02 parts of mycin, 5 parts of guanzhong alcohol extract, 1 part of orthosilicic acid and 100 parts of water are used as raw materials for the treatment solution, and bis(2-ethylhexyl)sulfonate sodium succinate, polyoxyethylene fatty alcohol ether Dissolve carboxymethyl chitosan and carboxymethyl chitosan ultrasonically in water, heat up to 60°C, add the ethanol extract and stir at a speed of 500r / min for 2 hours, then cool down to room temperature, add neomycin and orthosilicic acid and mix until uniform. treatment fluid;

[0020] The ethanol extract of the rhubarb is prepared by the following method: take the washed an...

Embodiment 2

[0025] The preparation technology of a kind of multifunctional seaweed fiber fabric that the present invention proposes, comprises the following steps:

[0026] S1. Preparation of treatment solution: In parts by weight, weigh 2 parts of sodium bis(2-ethylhexyl) sulfosuccinate, 0.4 parts of polyoxyethylene fatty alcohol ether, 4 parts of carboxymethyl chitosan, and 0.025 parts of mycin, 6 parts of guanzhong alcohol extract, 1.4 parts of orthosilicic acid and 100 parts of water are used as the raw materials of the treatment solution, and the sodium bis(2-ethylhexyl)sulfonate, polyoxyethylene fatty alcohol ether Dissolve carboxymethyl chitosan and carboxymethyl chitosan ultrasonically in water, raise the temperature to 55°C, add the ethanol extract and stir at a speed of 550r / min for 1.5h, then cool down to room temperature, add neomycin and orthosilicic acid and mix until uniform get treatment fluid;

[0027] The ethanol extract of the rhubarb is prepared by the following metho...

Embodiment 3

[0032] The preparation technology of a kind of multifunctional seaweed fiber fabric that the present invention proposes, comprises the following steps:

[0033] S1. Preparation of treatment solution: In parts by weight, weigh 2 parts of sodium bis(2-ethylhexyl) sulfosuccinate, 0.5 parts of polyoxyethylene fatty alcohol ether, 4.5 parts of carboxymethyl chitosan, and 0.03 part of mymycin, 8 parts of guanzhong alcohol extract, 2 parts of orthosilicic acid and 100 parts of water are used as the raw materials of the treatment solution, and the sodium bis(2-ethylhexyl)sulfonate, polyoxyethylene fatty alcohol ether Dissolve carboxymethyl chitosan and carboxymethyl chitosan ultrasonically in water, heat up to 55°C, add the ethanol extract and stir at a speed of 600r / min for 1.5h, then cool down to room temperature, add neomycin and orthosilicic acid and mix until uniform get treatment fluid;

[0034] The ethanol extract of the rhubarb is prepared by the following method: take the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com