Preparation method of plant-source slow-release antibacterial aerogel

An airgel and plant-sourced technology, which is applied in pulp beating methods, textiles and papermaking, and fiber raw material processing, can solve the problems of antibacterial agent consumption, high concentration, and damage to the quality of packaged products, so as to extend shelf life, The effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

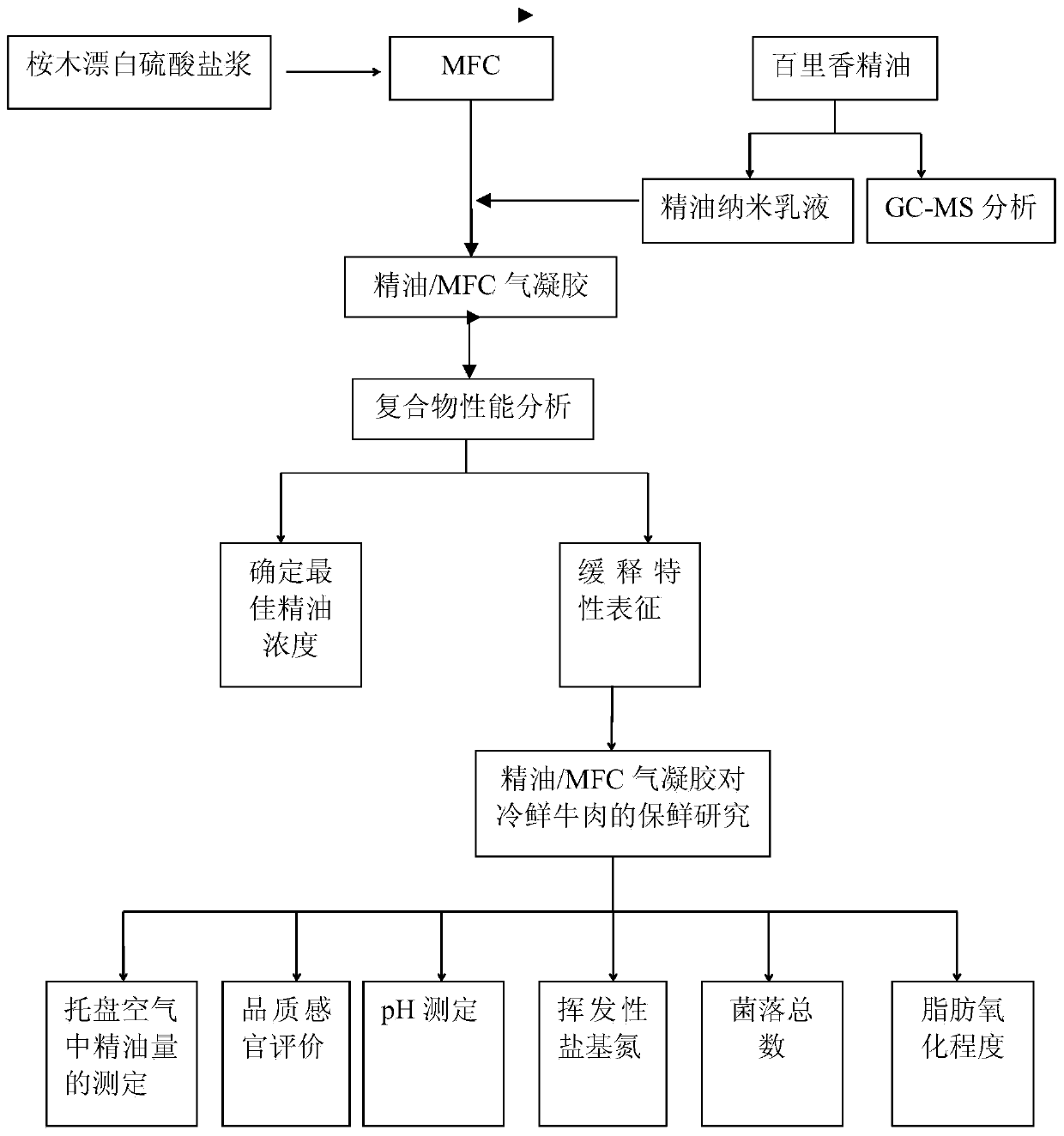

Method used

Image

Examples

Embodiment 1

[0045] Preparation of MFC / thyme essential oil slow-release antibacterial airgel by enzyme pretreatment

[0046] (1) Preparation of MFC by enzyme pretreatment

[0047] 1) Beating treatment before Valli: Weigh 360g of dry eucalyptus bleached kraft pulp, soak it for a certain period of time, put it into the Valli beater and add distilled water to dissolve it for a period of time, and stop beating when the beating degree is 30°SR The pulp was shaken dry and stored at 4°C for later use.

[0048] 2) Cellulase pretreatment: add a certain amount of distilled water to make 30°SR pulp into a 10% concentration slurry, then add 6U / g enzyme stock solution, put it in a 60°C water bath for 16 hours, and the reaction is over Then put the slurry into an 80°C water bath and keep it warm for 30 minutes. After inactivating the enzyme, use a Buchner funnel to wash and filter with distilled water. The filtered slurry is stored for future use.

[0049]3) Post-PFI beating treatment: use a PFI refin...

Embodiment 2

[0062] Preparation of MFC / thyme essential oil sustained-release antibacterial airgel by TEMPO oxidation pretreatment

[0063] (1) Preparation of MFC by TEMPO oxidation pretreatment

[0064] 1) Beating treatment before Valli: Weigh 360g of dry eucalyptus bleached kraft pulp, soak it for a certain period of time, put it into the Valli beater and add distilled water to dissolve it for a period of time, and stop beating when the beating degree is 30°SR The pulp was shaken dry and stored at 4°C for later use.

[0065] 2) Put the 1% slurry into a three-necked flask and stir for 4 hours, then pour the mixture of TEMPO (1% of MFC absolute dry weight) and NaBr (10 times the amount of TEMPO) into the container, and use 0.5mol / L Adjust the pH of the NaOH solution to 10.5; use a disposable dropper to drop 10% NaClO solution dropwise into the three-necked flask, and keep the pH of the mixture between 10 and 11 by adding 0.5mol / L NaOH ; When the pH value of the mixed system no longer chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com