Ammonia volume control system based on gas-solid phase transition

A control system, gas-solid phase technology, applied in the direction of airbag arrangement, fixed tubular catheter assembly, compression machine with reversible cycle, etc., can solve the problems of low efficiency, heavy burden, bulky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

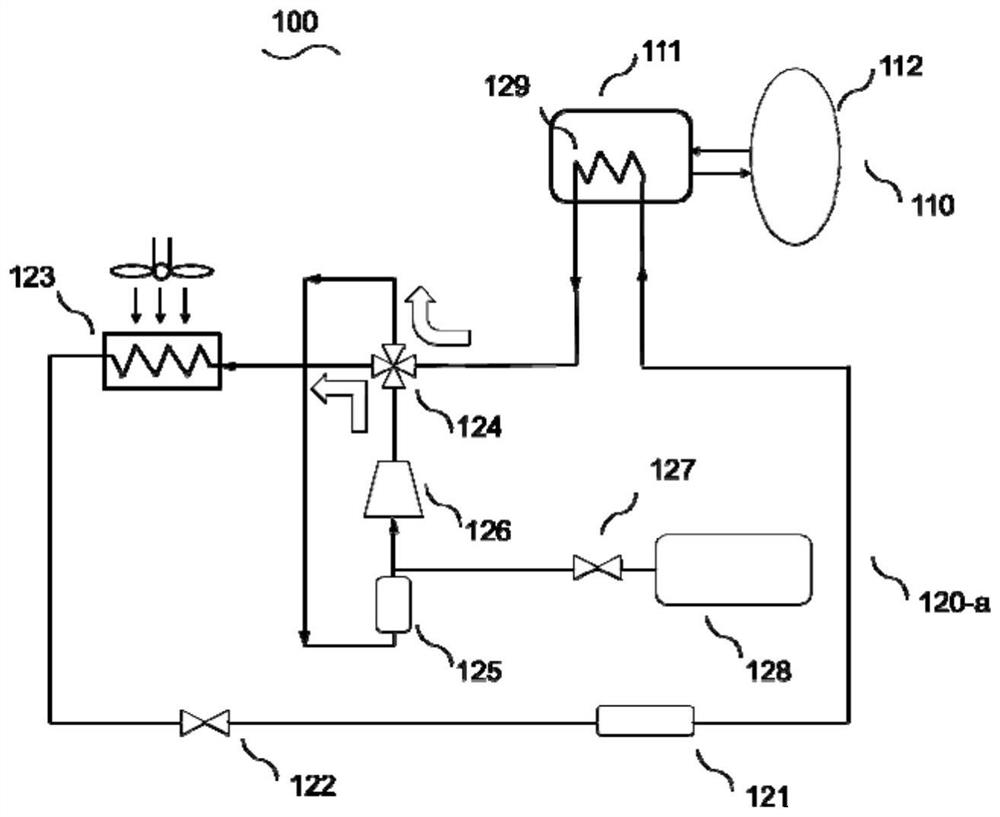

[0033] see figure 1 , is an ammonia volume control system 100 based on gas-solid phase transition according to an embodiment of the present invention, including: an ammonia volume control unit 110 and a refrigeration cycle unit 120-a.

[0034] The ammonia volume control unit 110 includes a heat exchange module 111 and an ammonia air bag 112, the low-pressure ammonia gas is connected to the inlet of the heat exchange module 111 by the outlet of the ammonia air bag 112 through a connecting pipe, and the outlet of the heat exchange module 111 A pipeline is connected to the inlet of the ammonia gas bag 112 .

[0035] The ammonia volume control unit 110 provided by the present invention works in the following manner: if the amount of ammonia gas is reduced, the low-pressure ammonia gas enters the heat exchange module 111 from the ammonia gas bag 112 and becomes solid when it is cooled; if the amount of ammonia gas is increased , the solid ammonia in the heat exchange module 111 be...

Embodiment 2

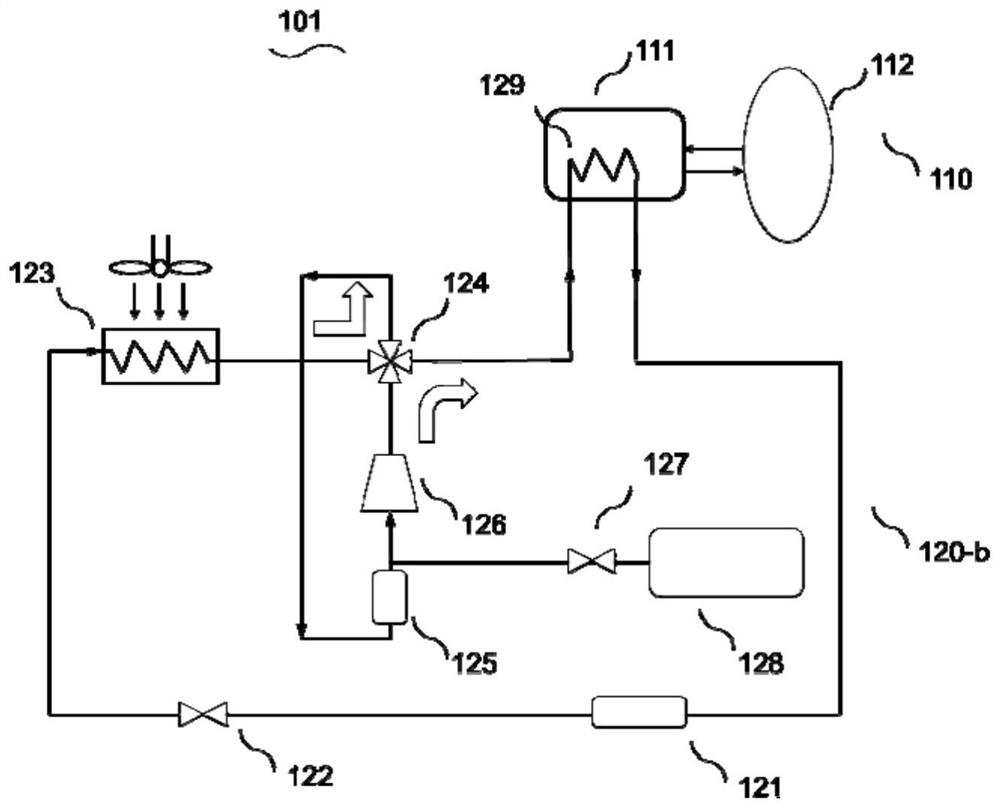

[0046] see figure 2 , is an ammonia volume control system 101 based on gas-solid phase transition according to an embodiment of the present invention, including: an ammonia volume control unit 110 and a refrigeration cycle unit 120-b.

[0047] The ammonia volume control unit 110 includes a heat exchange module 111 and an ammonia air bag 112, the low-pressure ammonia gas is connected to the inlet of the heat exchange module 111 by the outlet of the ammonia air bag 112 through a connecting pipe, and the outlet of the heat exchange module 111 A pipe is connected to the inlet of the ammonia gas bag 112 .

[0048] The ammonia volume control unit 110 provided by the present invention works in the following manner: if the amount of ammonia gas is reduced, the low-pressure ammonia gas enters the heat exchange module 111 from the ammonia gas bag 112 and becomes solid when it is cooled; if the amount of ammonia gas is increased , the solid ammonia in the heat exchange module 111 becom...

Embodiment 3

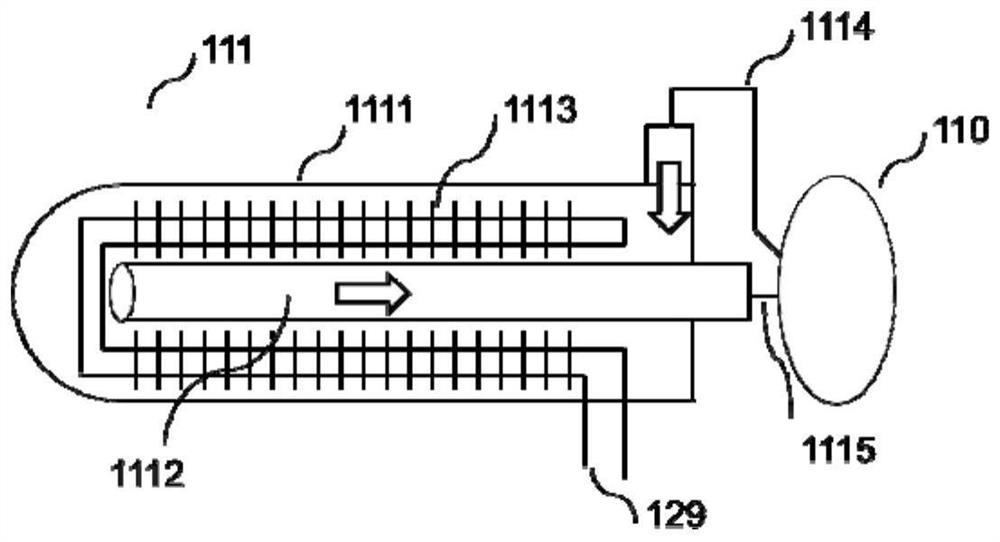

[0059] see image 3 , is a schematic structural diagram of the ammonia volume control unit provided by an embodiment of the present invention.

[0060] The ammonia volume control unit 110 includes a heat exchange module 111 and an ammonia air bag 112, the heat exchange module includes an outer shell 111, an inner pipe 1112 arranged in the outer shell 1111, an inner pipe 1112 arranged in the outer shell 1111 and the inner pipe 1112 The fins 1113 between them and the connecting pipes 1114 and 1115 are formed.

[0061] In this embodiment, the outer shell 1111 is a combination of a cylindrical shape and a hemispherical shape, and the inner pipe 1112 is a cylindrical shape.

[0062] In this embodiment, the outer casing 1111 and the inner pipeline 1112 are respectively connected to the ammonia air bag 110 through a connecting pipeline 1114 (1115), and the low-pressure ammonia gas enters the heat exchange module 111 from the pipeline 1114 connected to the outer casing 1111 , and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com