Shooting guiding type dynamic detection system for wind power blade defect of unmanned aerial vehicle and method thereof

A technology for dynamic detection of wind power blades, which is applied in the field of camera measurement technology and moiré detection, can solve the problems of not being able to find mechanical failures of blades in time, hindering the sustainable development of wind power industry, and few detection items, achieving rich functions, saving manpower, The effect of detecting process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a camera-guided dynamic detection system for drone wind turbine blade defects, which is characterized in that it includes the following systems:

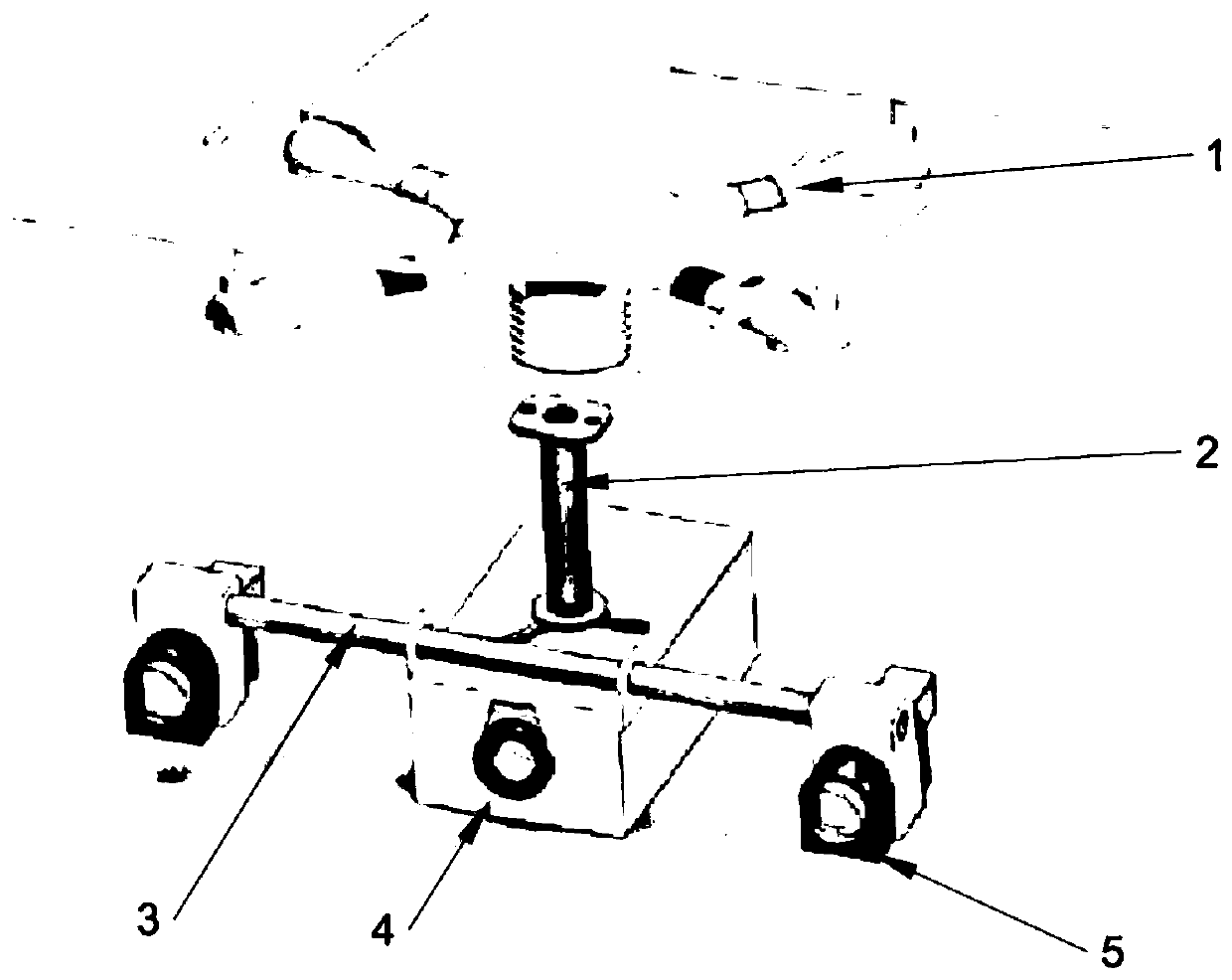

[0031] The blade global motion measurement system is set on the ground: an embodiment of the present invention figure 1 As shown, it includes two independent global camera measurement platforms. The distance and intersection angle of the two global camera measurement platforms are flexibly arranged according to the requirements of the measurement task. They are used for three-dimensional motion measurement and image edge profile measurement of wind turbine blades, and obtain the blade motion state And overall integrity. For example, it is composed of 2×2=4 megapixel-level high-resolution cameras, which take a series of images of about 130×130 square meters of the wind turbine blade in the rotating state. Using the principle of stereo vision between the two measurement platforms, the three-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com