Simulation method for manufacturing three-dimensional atom probe sample process by FIB based on MATLAB

An atom probe and process simulation technology, applied in scanning probe technology, instruments, etc., can solve the problems of complex FIB processing process, sample preparation in indeterminate area, separation of sample and base, etc., to improve the purpose and success rate, The effect of complete programming visualization function and efficient numerical calculation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

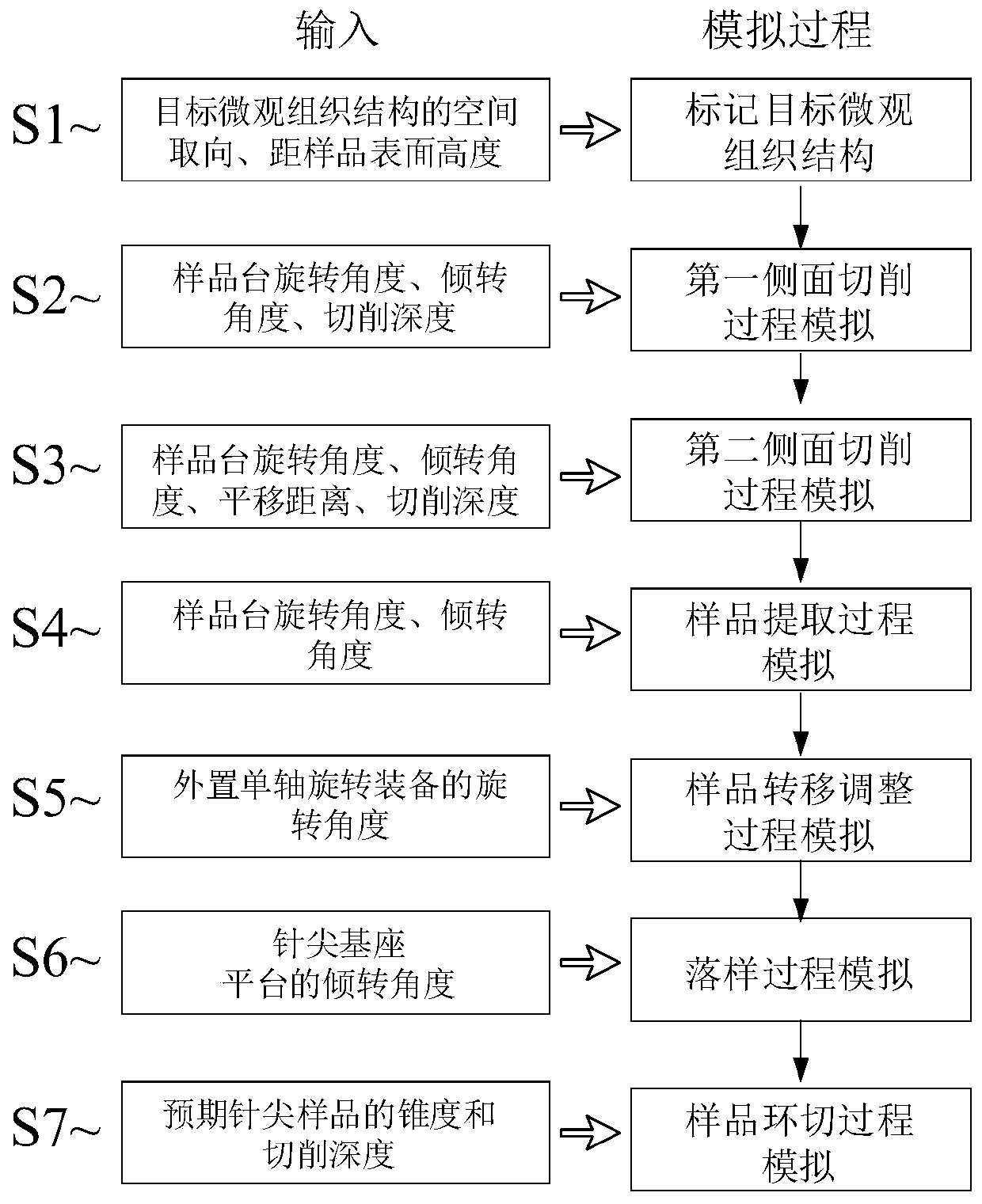

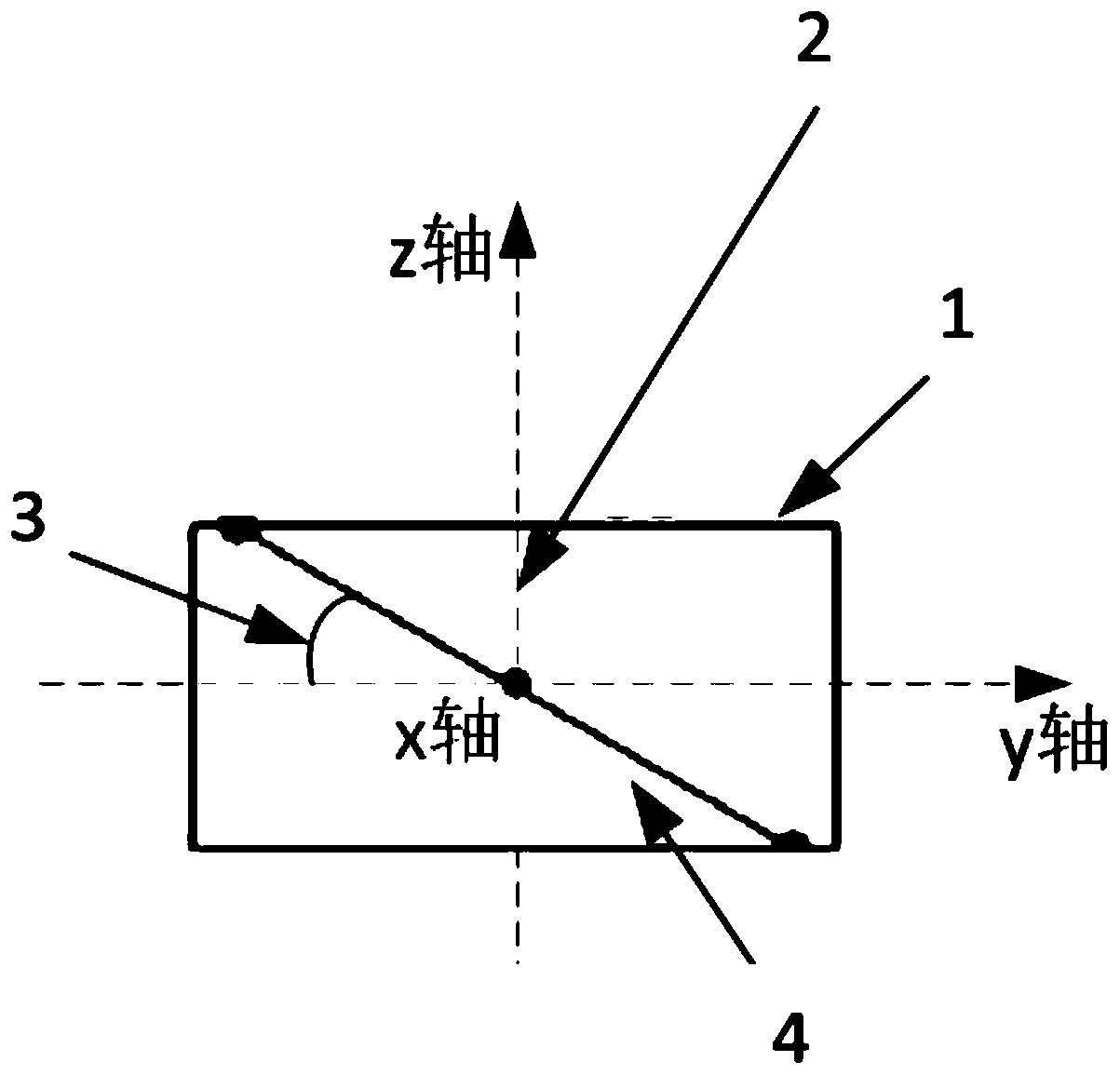

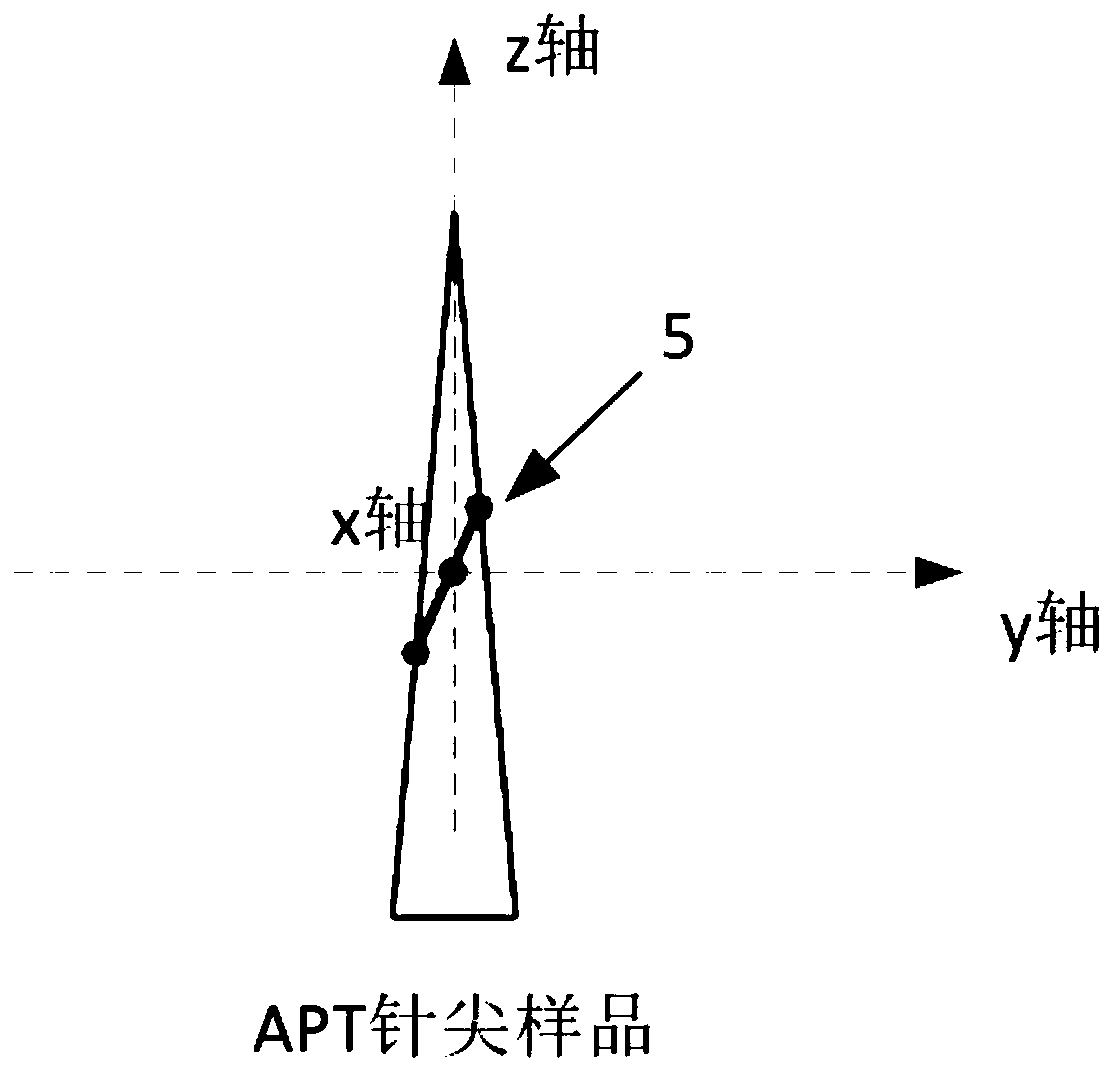

[0032] like figure 1 As shown, a MATLAB-based FIB simulation method for preparing an APT sample process includes the following steps, S1, first marking the spatial position of the target microstructure in the material to be tested. Since the microstructure of the sample surface is obtained by SEM, EBSD and other characterization means, therefore, as figure 2 As shown, the spatial position information of the target microstructure is the distance 2 between the target microstructure and the sample surface, the orientation angle 3 of the target microstructure, and the trace 4 of the target microstructure on the end surface.

[0033] S2, by setting the rotation angle R of the sample stage 1 , tilt angle T 1 and depth of cut H 1 , to simulate the first side cutting process. The rotation angle R of the sample stage 1, tilt angle T 1 Based on the angle range that can be realized by the current mainstream FIB / SEM equipment; and the cutting depth H 1 Determined according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com