Sand-stone separator

A technology of sand and gravel separator and sand separator, which is applied in solid separation, wet separation, filter and screen, etc., which can solve problems such as non-compliance with environmental protection requirements, blockage of urban sewer pipes, interference with the direction of travel of mixer trucks and forklifts, etc. Achieve the effects of saving civil engineering costs and floor space, reducing the height of the main engine, and reducing the probability of material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

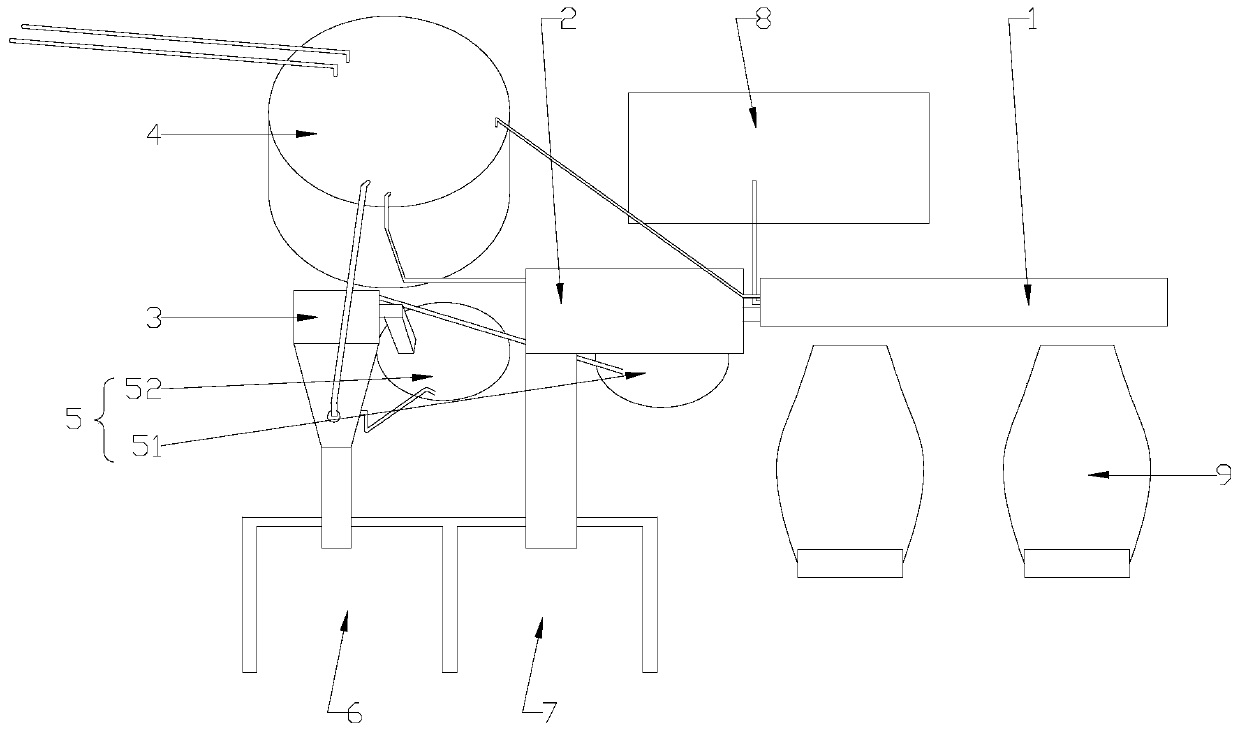

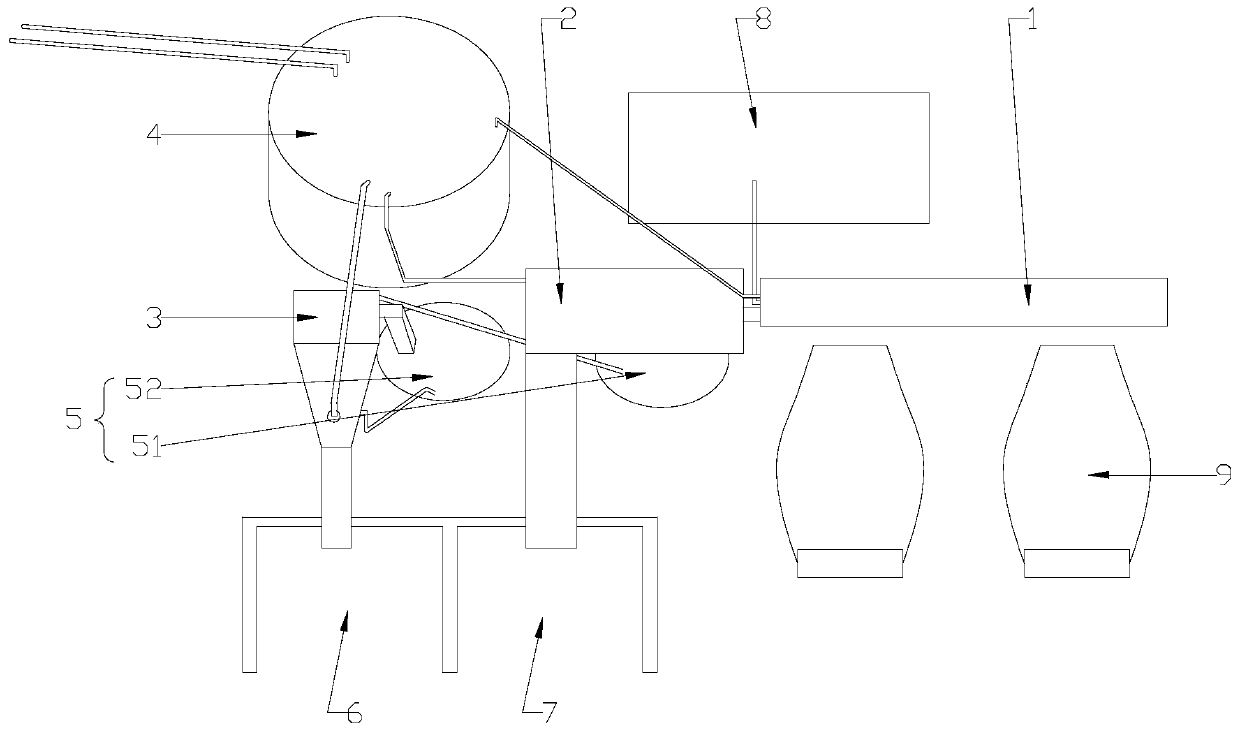

[0021] refer to figure 1 , a kind of sand and gravel separator of the present invention, comprises guide tank 1, trommel 2, spiral sand divider 3, stirring tank 4, conical pool 5, sand stockyard 6, stone stockyard 7 and pool 8, described The material guide tank 1 is connected with the pool 8 and the trommel 2 respectively through pipelines, and the conical pool 5 includes a first mud pool 51 and a second mud pool 52, and the first mud pool 51 and the second mud pool 52 are respectively It is located under the trommel 2 and the spiral sand separator 3 and is respectively connected to the trommel 2 and the spiral sand separator 3 through pipelines. The rock outlet of the trommel 2 and the sand outlet of the spiral sand separator 3 are respectively provided Leading to the conveyor belt of the stone stockyard 7 and the sand stockyard 6, the mixing tank 4 is connected with the spiral sand separator 3 through a pipeline, the trough 1 is provided with a flushing pump and a flushing n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com