Multi-crop oil press

A technology for oil presses and crops, applied in presses, grain processing, manufacturing tools, etc., can solve the problems of oil residues that cannot be processed twice, low oil extraction efficiency, waste, etc., to save manpower and improve oil extraction Efficiency, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

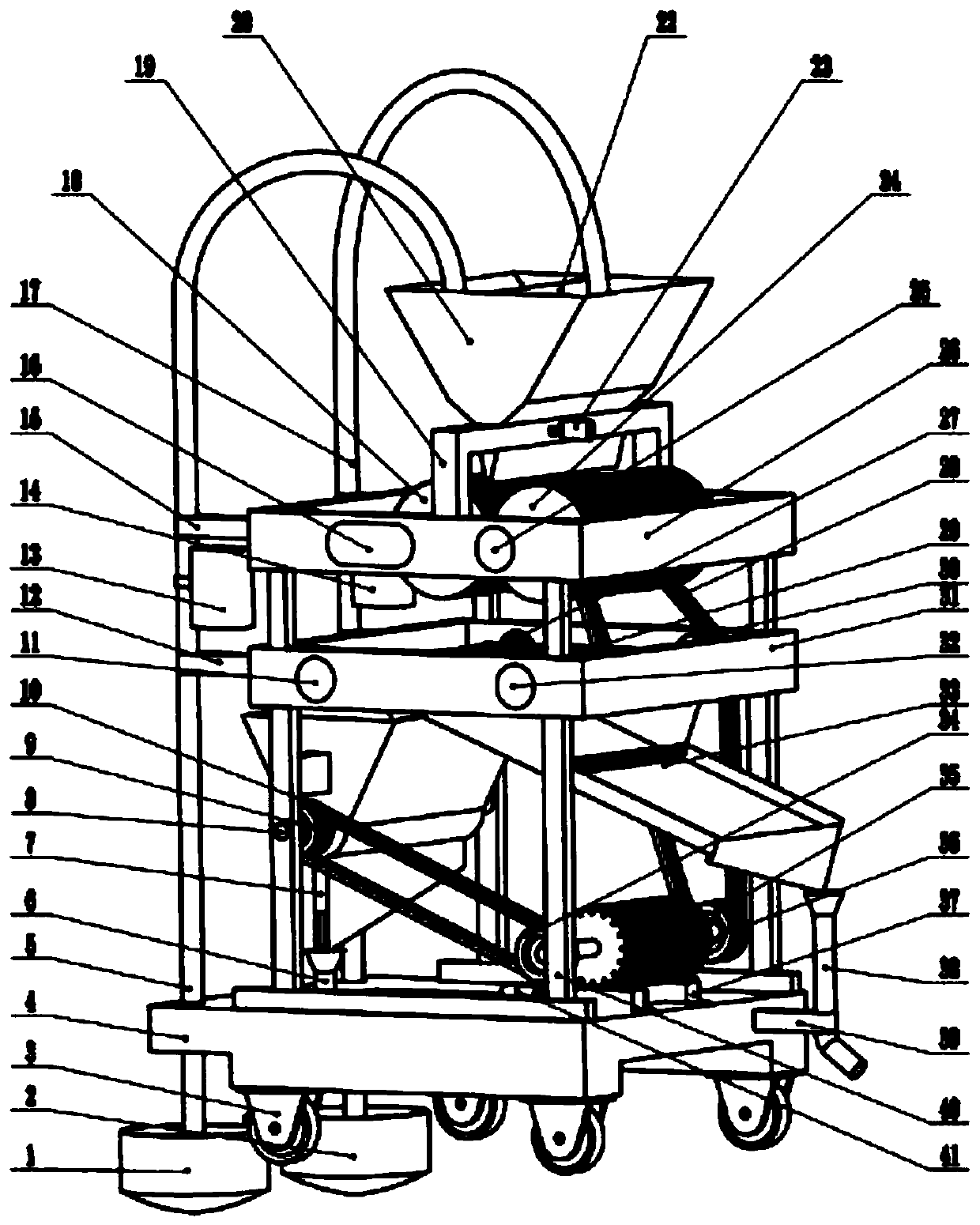

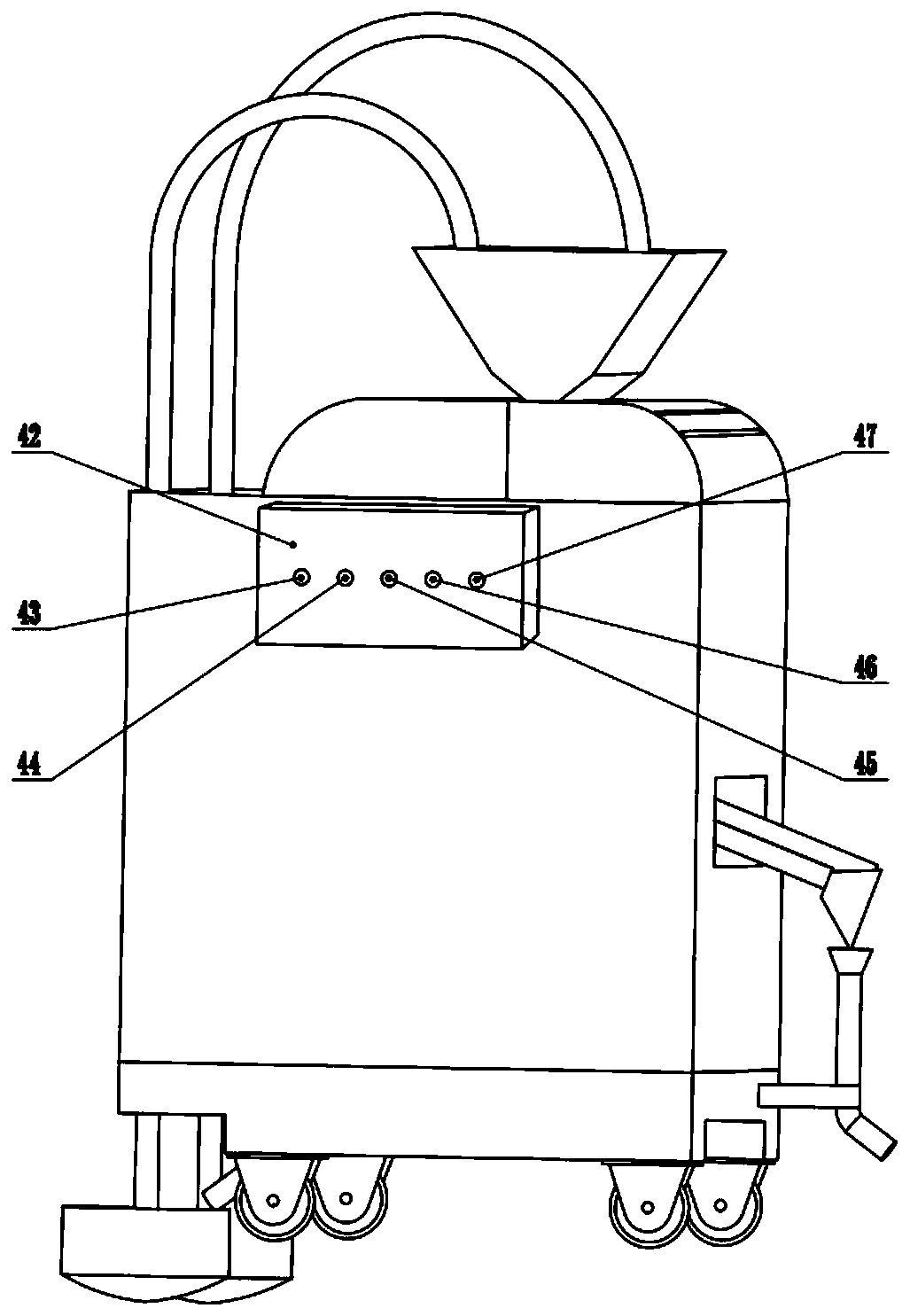

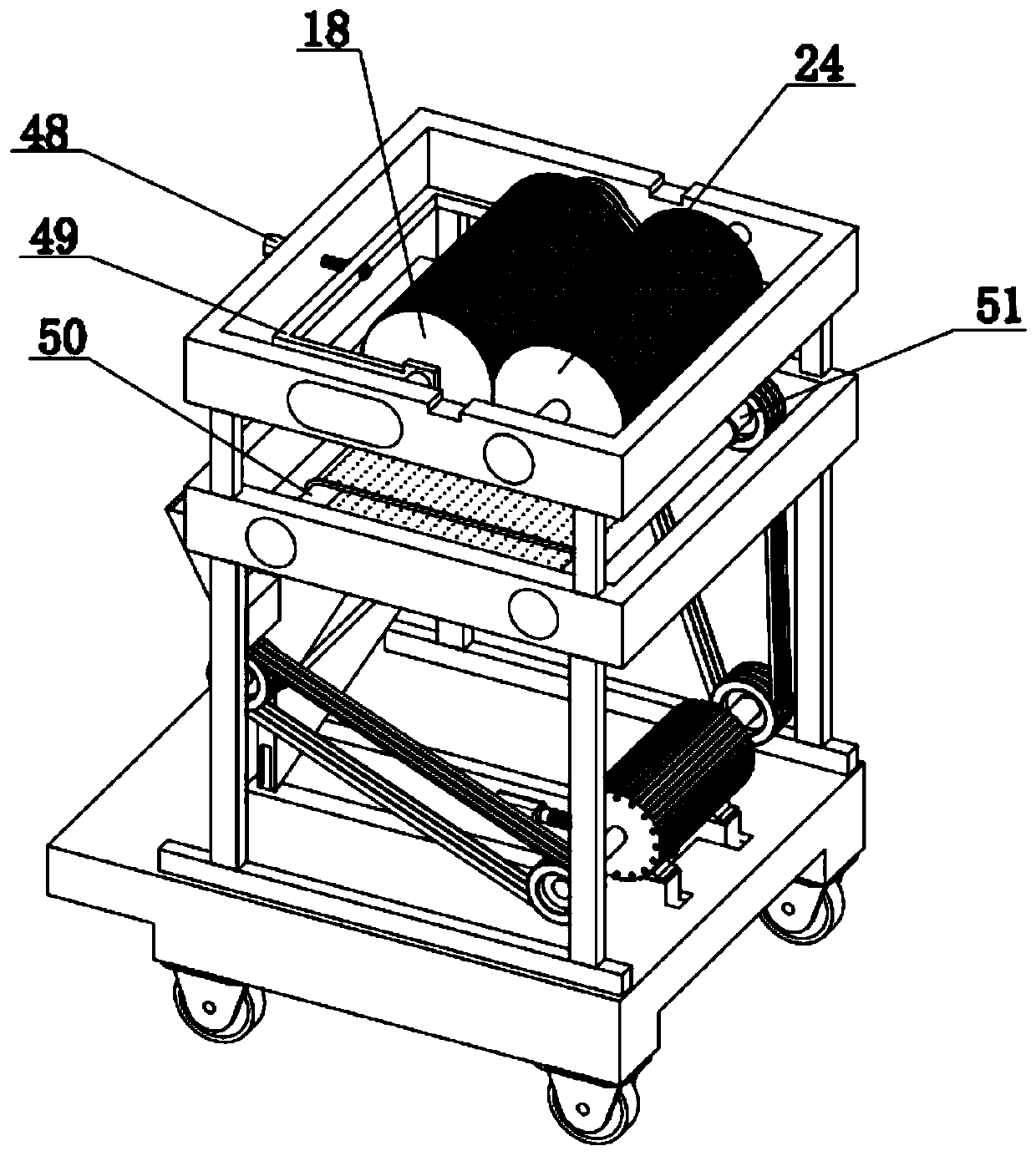

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, the multi-crop oil press machine includes a machine base 4, a steering wheel 3 is arranged at the bottom of the machine base, a motor support 37 is arranged on the machine base 4, and a pulley 34 and a pulley 35 are installed at both ends of the biaxial motor 36. Motor 36 is fixed on the motor support 37, connects upper connecting frame 26 and intermediate connecting frame 31 by connecting bracket 40 on the support 4, is provided with feeding hopper support 19 on the upper connecting frame 26, connects feeding hopper 20 on the feeding hopper support 19 , feeding hopper 20 is divided into two feeding chambers by dividing plate 22, and stepping motor 23 is set on feeding hopper support 19, and the effect of stepping motor 23 is to adjust feeding speed, and the part that stepping motor 23 controls is feeding speed regulating plate 21 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com