Cathode electrophoretic coating with high throwing power and preparation method of cathode electrophoretic coating

A cathodic electrophoretic coating and penetrating power technology, applied in electrophoretic coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor weather resistance, low penetrating power, and poor edge coverage of the oxidized layer, and achieve corrosion resistance. Strong, penetrating power, and the effect of increasing hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

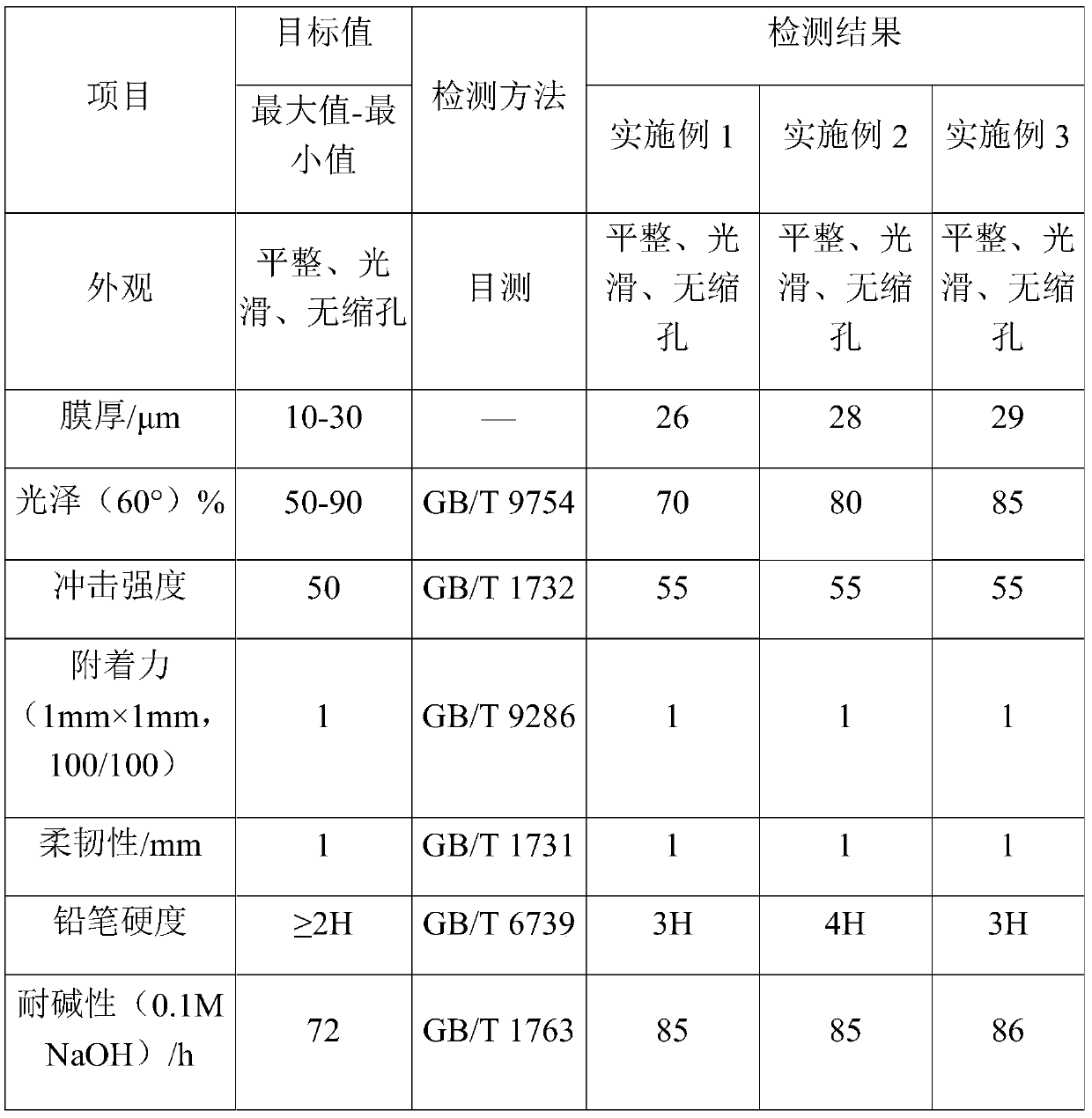

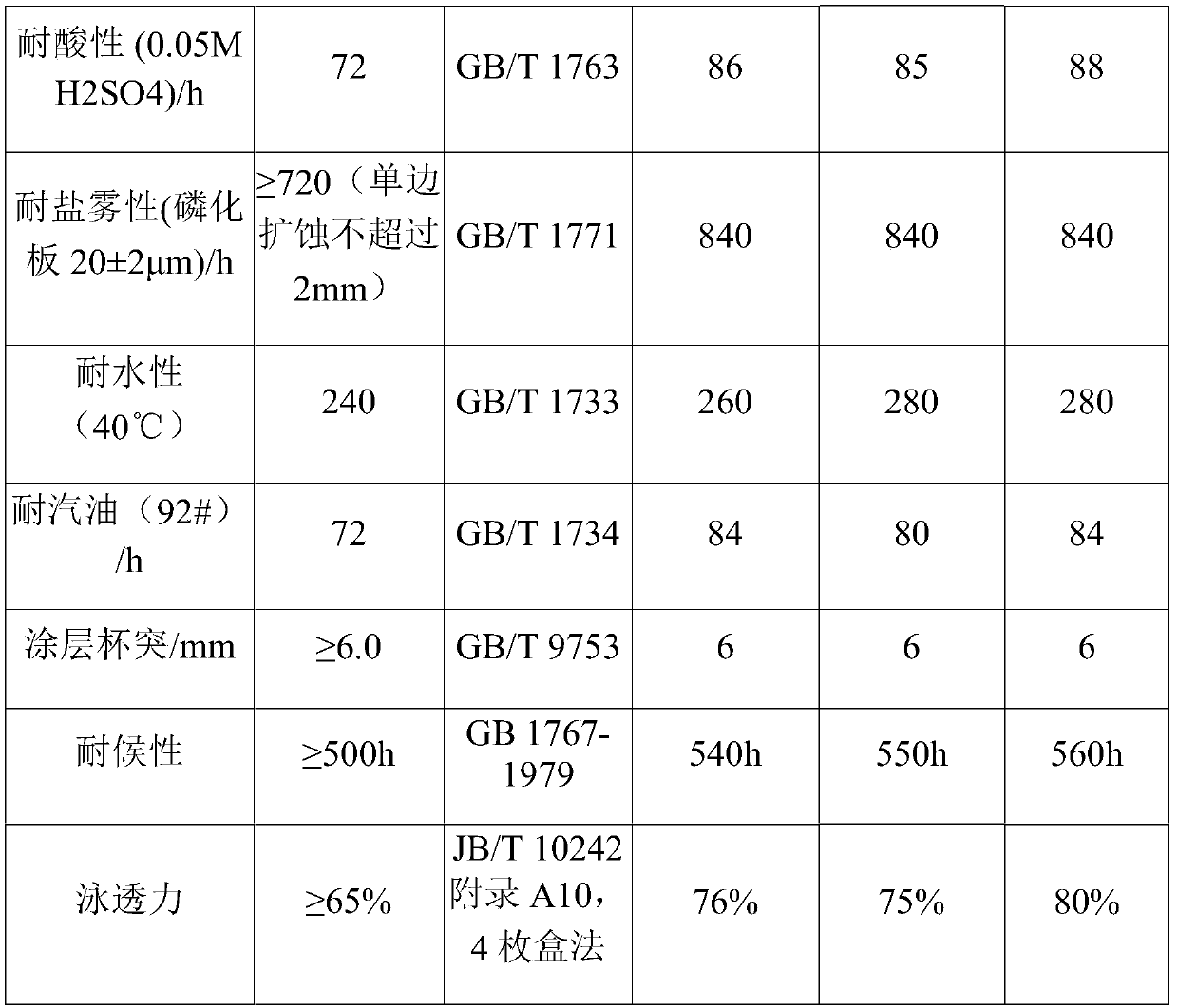

Embodiment 1

[0035] The embodiment of the present invention provides a cathodic electrophoretic coating with high throwing power. The raw materials include the following components in parts by weight: 15 parts of color paste, 55 parts of emulsion, and 50 parts of deionized water;

[0036] The above-mentioned color paste includes the following components in parts by mass: 18 parts of silicone modified acrylic resin, 5 parts of environmental protection cosolvent, 2 parts of neutralizer, 0.4 part of surfactant, 30 parts of deionization, 23 parts of kaolin, 9 parts of pigment ;

[0037] The above emulsion includes the following components in parts by mass: 40 parts of silicone-modified acrylic resin, 6 parts of emulsifier, 3 parts of neutralizer, and 45 parts of deionized water.

[0038] The above-mentioned pigment is carbon black, the environmentally friendly co-solvent is a mixture of dipropylene glycol methyl ether and ethylene glycol butyl ether, the neutralizer is acetic acid, the surfact...

Embodiment 2

[0045] The embodiment of the present invention provides a cathodic electrophoretic coating with high throwing power. The raw materials include the following components in parts by weight: 5 parts of color paste, 35 parts of emulsion, and 40 parts of deionized water;

[0046] The above-mentioned color paste includes the following components in parts by mass: 30 parts of silicone modified acrylic resin, 20 parts of environmental protection cosolvent, 7 parts of neutralizer, 1 part of surfactant, 45 parts of deionization, 27 parts of kaolin, 25 parts of pigment ;

[0047] The above emulsion includes the following components in parts by mass: 30 parts of silicone-modified acrylic resin, 4 parts of emulsifier, 10 parts of neutralizer, and 25 parts of deionized water.

[0048] The above-mentioned pigment is a mixture of carbon black, phthalocyanine blue and titanium dioxide with a quality of 2:3:5, the environmentally friendly co-solvent is a mixture of dipropylene glycol butyl ethe...

Embodiment 3

[0055] The embodiment of the present invention provides a cathodic electrophoretic coating with high throwing power. The raw materials include the following components in parts by weight: 10 parts of color paste, 70 parts of emulsion, and 50 parts of deionized water;

[0056] The above-mentioned color paste includes the following components in parts by mass: 10 parts of silicone-modified acrylic resin, 5 parts of environmentally friendly cosolvent, 5 parts of neutralizer, 0.1 part of surfactant, 20 parts of deionization, 5 parts of kaolin, and 10 parts of pigment ;

[0057] The above emulsion includes the following components in parts by mass: 35 parts of silicone-modified acrylic resin, 9 parts of emulsifier, 8 parts of neutralizer, and 45 parts of deionized water.

[0058] The above-mentioned pigment is a mixture of permanent violet, phthalocyanine blue and titanium dioxide with a quality of 1:3:7, the environmentally friendly co-solvent is a mixture of sec-butanol and dieth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com