A surface treatment agent for metal materials before cathodic electrophoretic coating

A surface treatment agent, cathodic electrophoresis technology, applied in metal material coating process, electrophoresis plating, coating and other directions, can solve the problems of low surface resistance of metal materials, sparse and non-dense film layers, etc. Good wettability and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

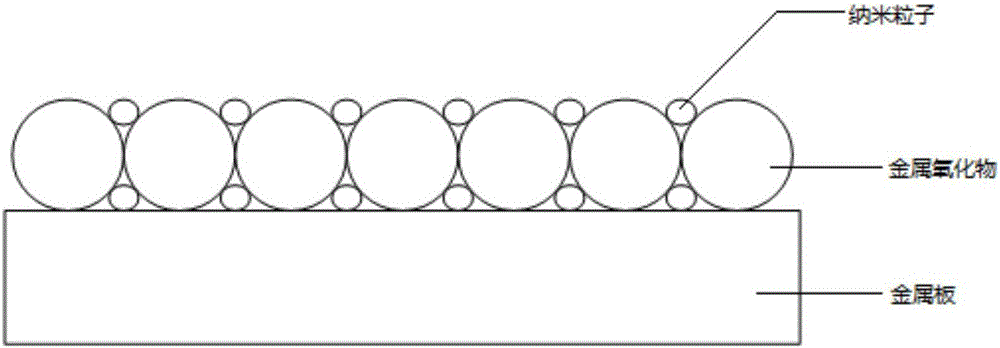

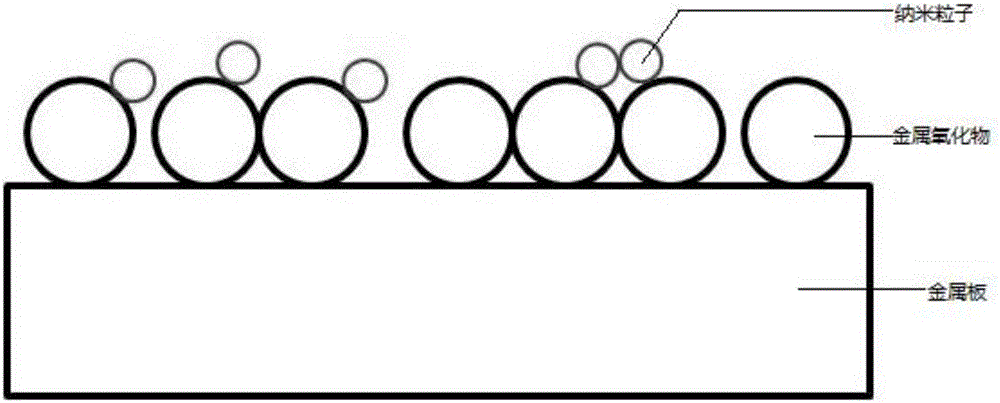

Method used

Image

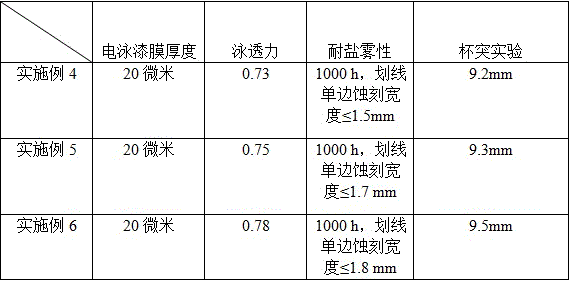

Examples

Embodiment 1

[0029] The present invention is used for the surface treatment agent before cathodic electrophoretic coating of metal materials. Each L of surface treatment agent consists of the following components: 100mg water-soluble oligosiloxane (Dynasylan Hydrosil 2926), 50mg zirconyl nitrate, 100mg titanyl sulfate, 100mg aluminum nitrate, 70mgLi 2 CO 3 , 100mg of sulfuric acid, 80mg of oxide nanoparticles grafted with amino groups and hydroxyl groups on the surface, 100mg of ethanol, 50mg of polyethylene glycol with a molecular weight of 600, 2mg of ferrous sulfate (ferrous sulfate can enhance the reactivity of the system and promote the occurrence of reactions and improve reaction efficiency) and the water balance; wherein, the grafted amount of hydroxyl groups on the surface of the oxide nanoparticles is 5 mmol / g, the grafted amount of amino groups on the surface of the oxide nanoparticles is 5 mmol / g, and the amount of grafted amino groups on the surface of the oxide nanoparticles i...

Embodiment 2

[0032] The present invention is used for the surface treatment agent before cathodic electrophoretic coating of metal materials. Each L of surface treatment agent consists of the following components: 80mg water-soluble oligosiloxane (Dynasylan Hydrosil 2926), 70mg water-soluble oligosiloxane Siloxane (Dynasylan Hydrosil 2776), 50mg fluozirconic acid, 100mg titanyl sulfate, 50mg aluminum nitrate, 50mg zinc sulfate, 70mg potassium hydroxide, 100mg nitric acid, 100mg oxide nanoparticles grafted with amino groups and hydroxyl groups on the surface, 120mg Ethanol, 80mg molecular weight is the polyethylene glycol of 600, 3mg ferrous sulfate and water balance; Wherein, the grafting amount of the hydroxyl group on the surface of the oxide nanoparticle is 1.4mmol / g, the amino group on the surface of the oxide nanoparticle The grafting amount was 3.8mmol / g, and the ratio of the grafting amount of hydroxyl groups and amino groups on the surface of oxide nanoparticles was 0.37.

[0033] Th...

Embodiment 3

[0035] The surface treatment agent used in the present invention before cathodic electrophoretic coating of metal materials is composed of the following components in each L of surface treatment agent: 50mg water-soluble oligosiloxane (Dynasylan Hydrosil 2926), 100mg water-soluble oligosiloxane Siloxane (Dynasylan Hydrosil 2776), 50mg fluozirconic acid, 100mg fluotitanic acid, 100mg zinc sulfate, 80mg ammonium bicarbonate, 120mg hydrofluoric acid, 100mg oxide nanoparticles grafted with amino and hydroxyl groups on the surface, 150mg ethanol, 100mg molecular weight is the polyethylene glycol of 600, 5mg ferrous sulfate and water surplus; Wherein, the grafting amount of the hydroxyl group on the surface of the oxide nanoparticle is 3.7mmol / g, the grafting amount of the amino group on the surface of the oxide nanoparticle The amount is 0.9mmol / g, and the ratio of the grafted hydroxyl groups and amino groups on the surface of oxide nanoparticles is 4.1.

[0036] The pH value of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting amount | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com