Multi-barrel pulsator washing machine

A pulsator washing machine and a large pulsator technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve problems such as cross-contamination, mutual pollution, and no unified dehydration function, and achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

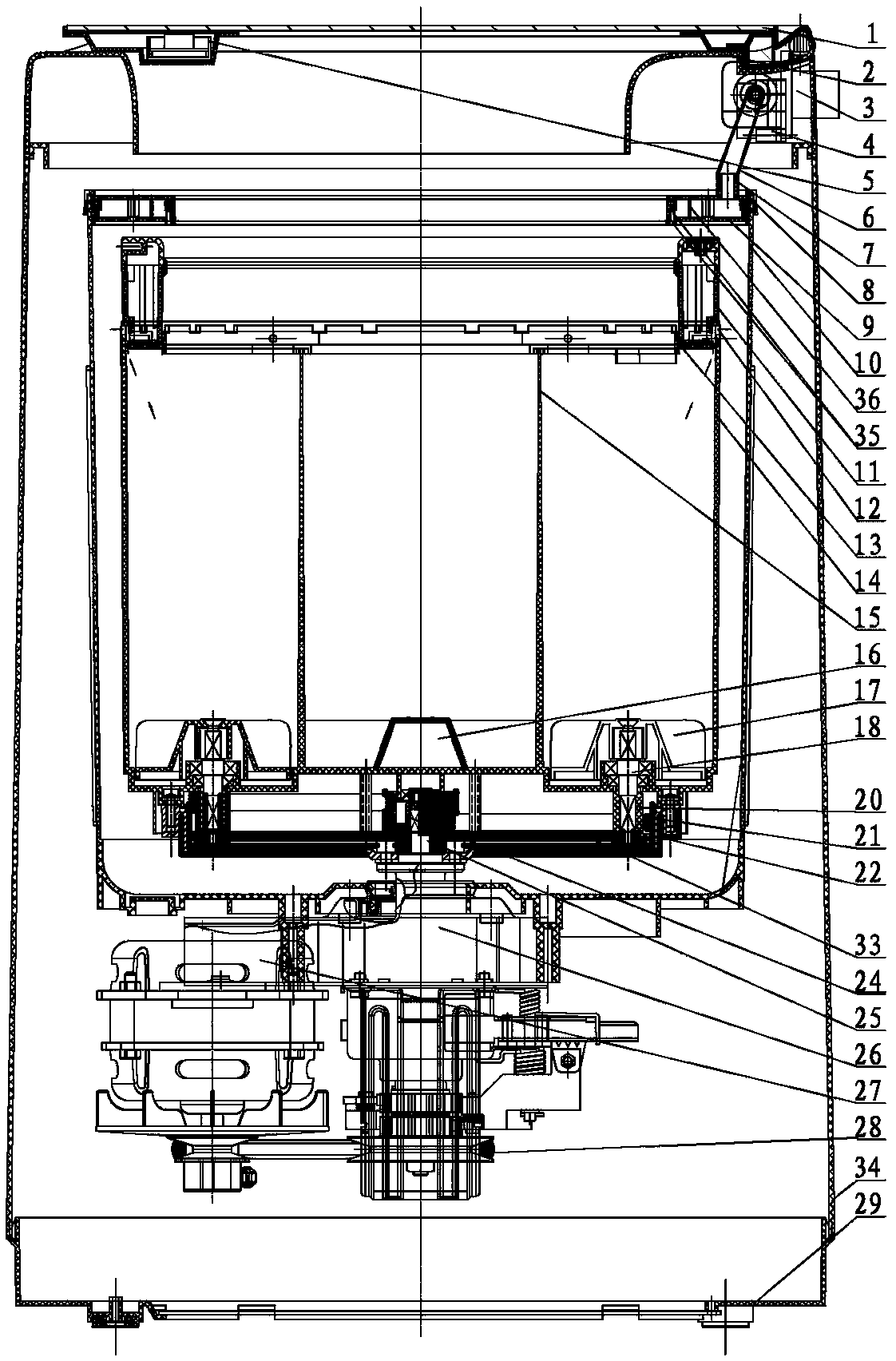

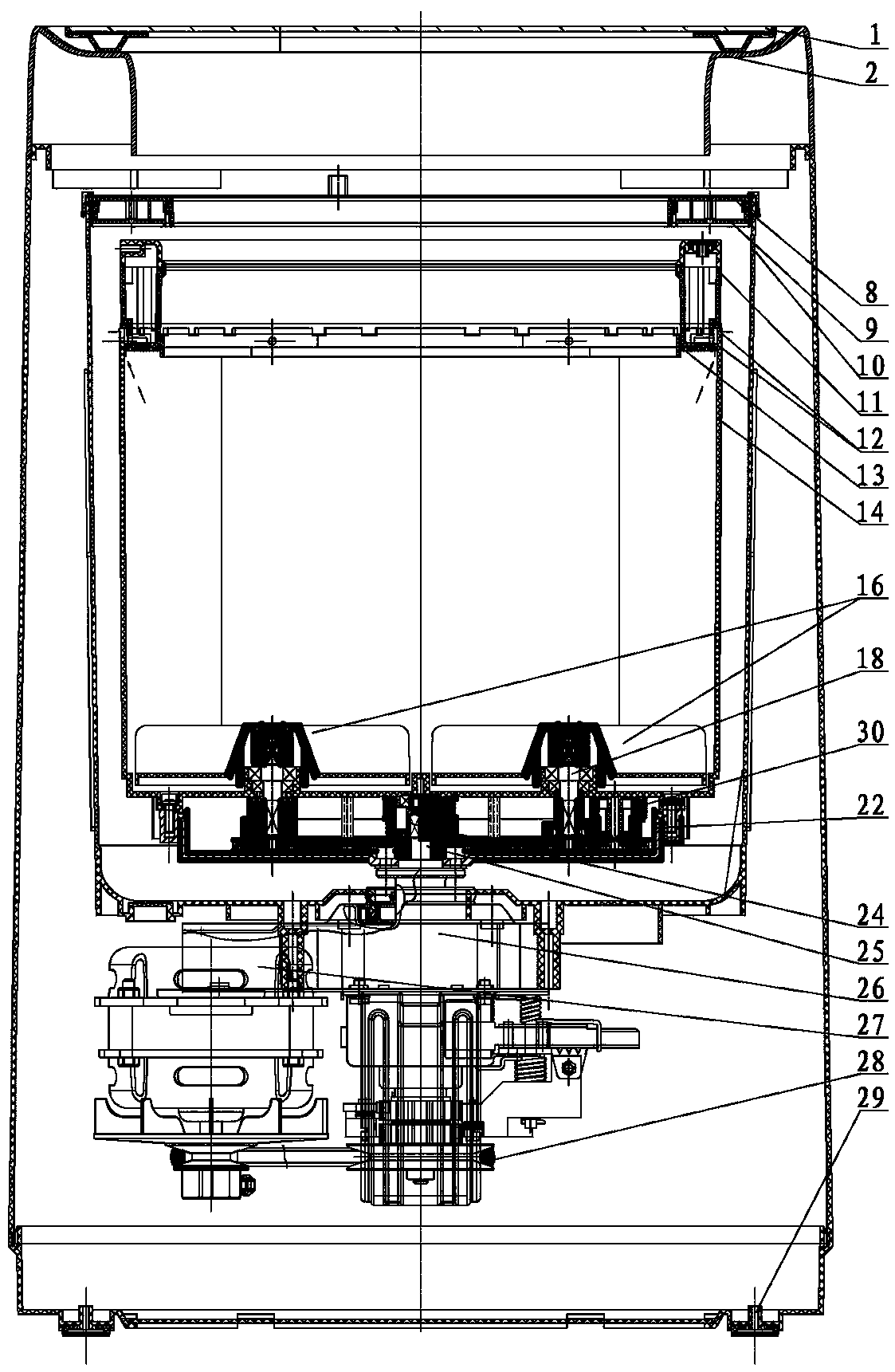

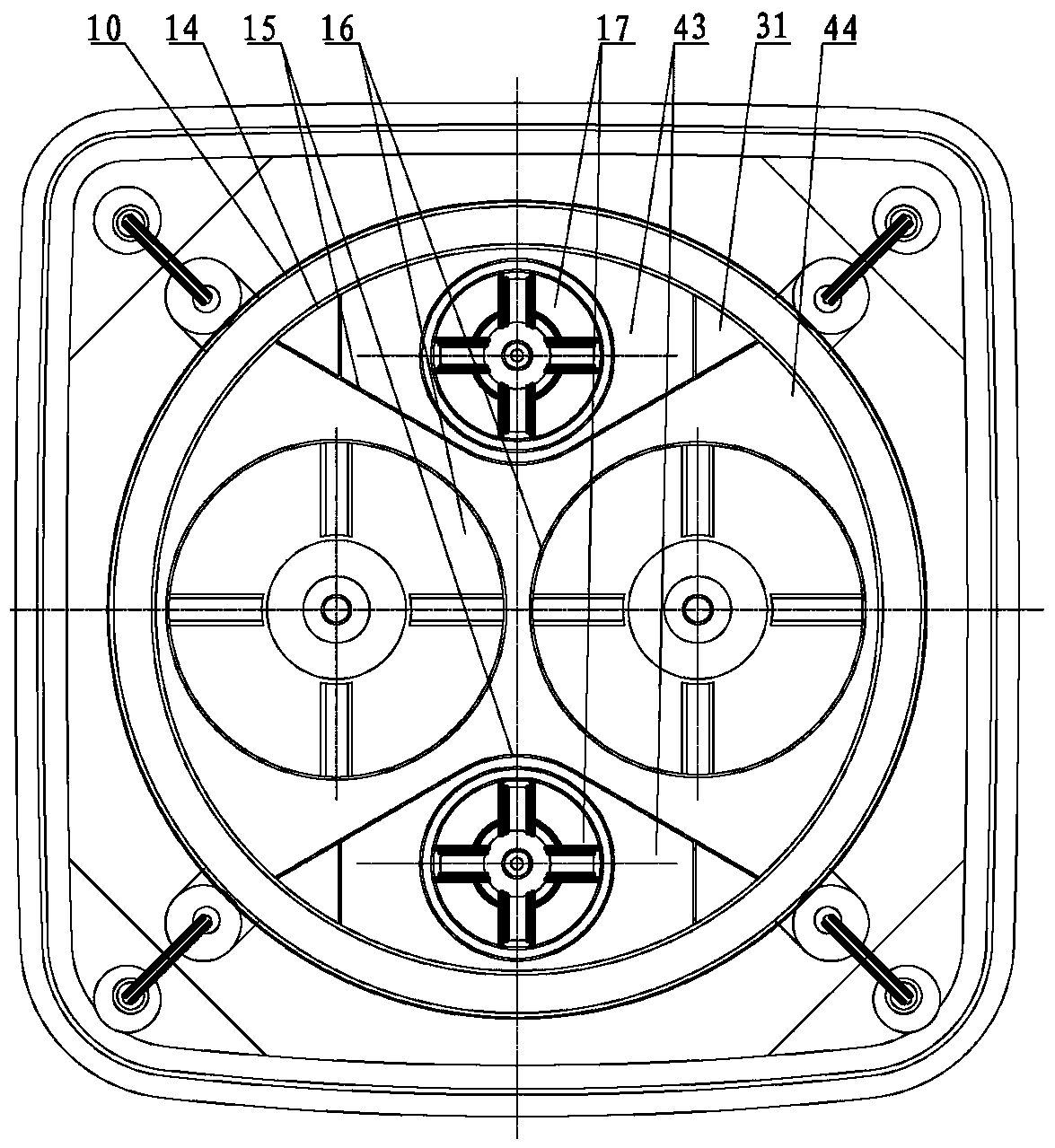

[0023] Figure 1-5 Shown, the washing machine loam cake 1 is housed on the casing 34, and the computer board 5 is placed on the disk base 2 near loam cake 1. The box body 34 is placed on the base 29 . Outer barrel 10 is installed in the casing 34, is suspended on the four corners of casing top by damping parts, and outer barrel cover 8 is housed on the top of outer barrel 10. The inner barrel 14 is concentrically installed in the outer barrel 10 , and the balance ring 11 is installed on the upper mouth of the inner barrel 14 . image 3 In the middle, perpendicular to the horizontal center line or the vertical center line image 3 The vertical plane is a plane of symmetry, and the inner barrel is divided into a large washing area 44 and two small washing areas 43 of plane symmetry by a dividing plate 15. A small wave wheel 17 is arranged on the bottom surface of the small washing area 43, and there are two small washing areas 44 on the bottom surface of the large washing area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com