High-filling-ratio loop thermosiphon based on multi-scale synergistic hydrophobic surface

A technology with hydrophobic surface and high liquid filling rate. It is used in heat transfer modification, heat exchange equipment, indirect heat exchangers, etc. It can solve the problems of poor stable operation effect at low power, etc., to broaden the scope of power application and reduce flow resistance. , the effect of reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

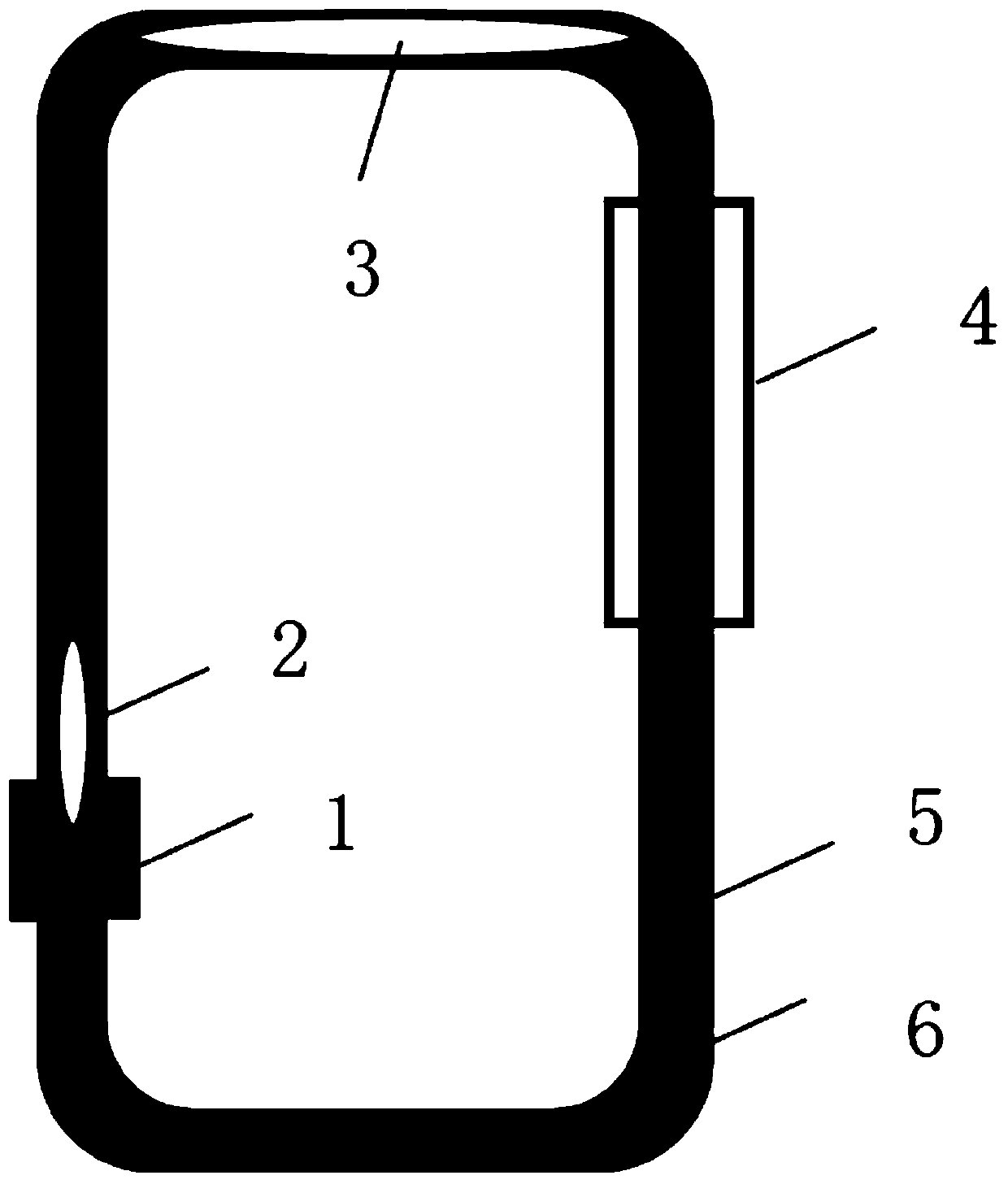

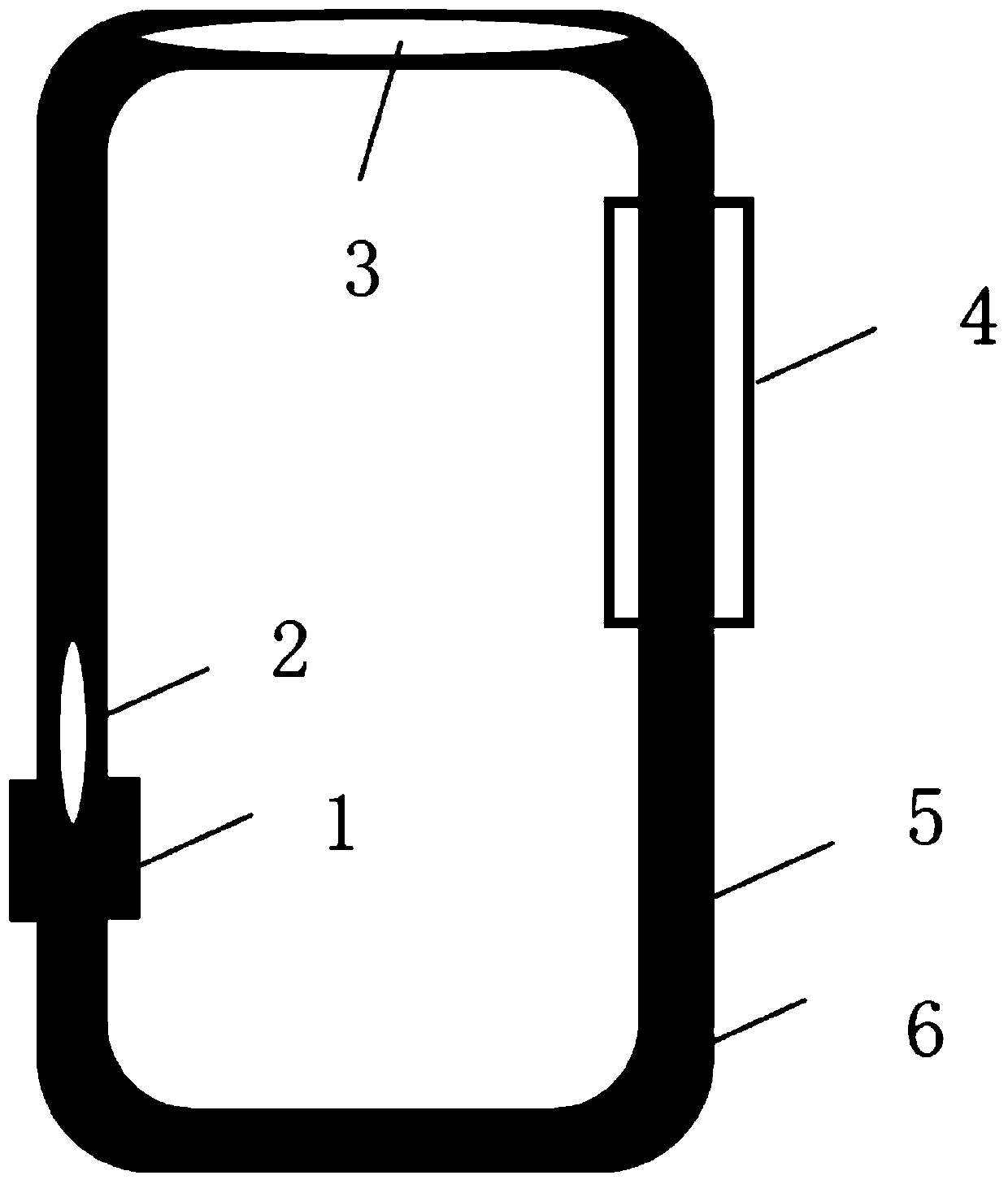

[0023] Such as figure 1 As shown, for the loop thermosiphon with high liquid filling rate, before heating and when the pipeline is not full, there is a certain gas phase zone 3 at the top of the pipeline. After heating in heating zone 1, the liquid near heating zone 1 The phase change of the heat transfer working medium 6 produces bubbles 2. Under the action of the density difference, the bubbles 2 move upwards and squeeze the gas in the gas phase region 3 at the top. The thermal working medium 6 moves to generate a circulation velocity in the pipeline, so that there are two heat transfer modes of liquid convection and liquid phase evaporation and boiling in the heating zone 1. Since the liquid heat transfer medium 6 is not easy to be compressed, when the bubble 2 is generated, the corresponding gas phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com