Non-magnetic temperature control system and non-magnetic temperature control method for SERF atom gas chamber

A technology of atomic gas chamber and temperature control system, which is applied in the direction of steering induction equipment, etc., can solve the problems of unheated body temperature measurement and feedback, SERF gyroscope signal interference, and difficulty in engineering implementation, so as to eliminate magnetic field interference and facilitate temperature control , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

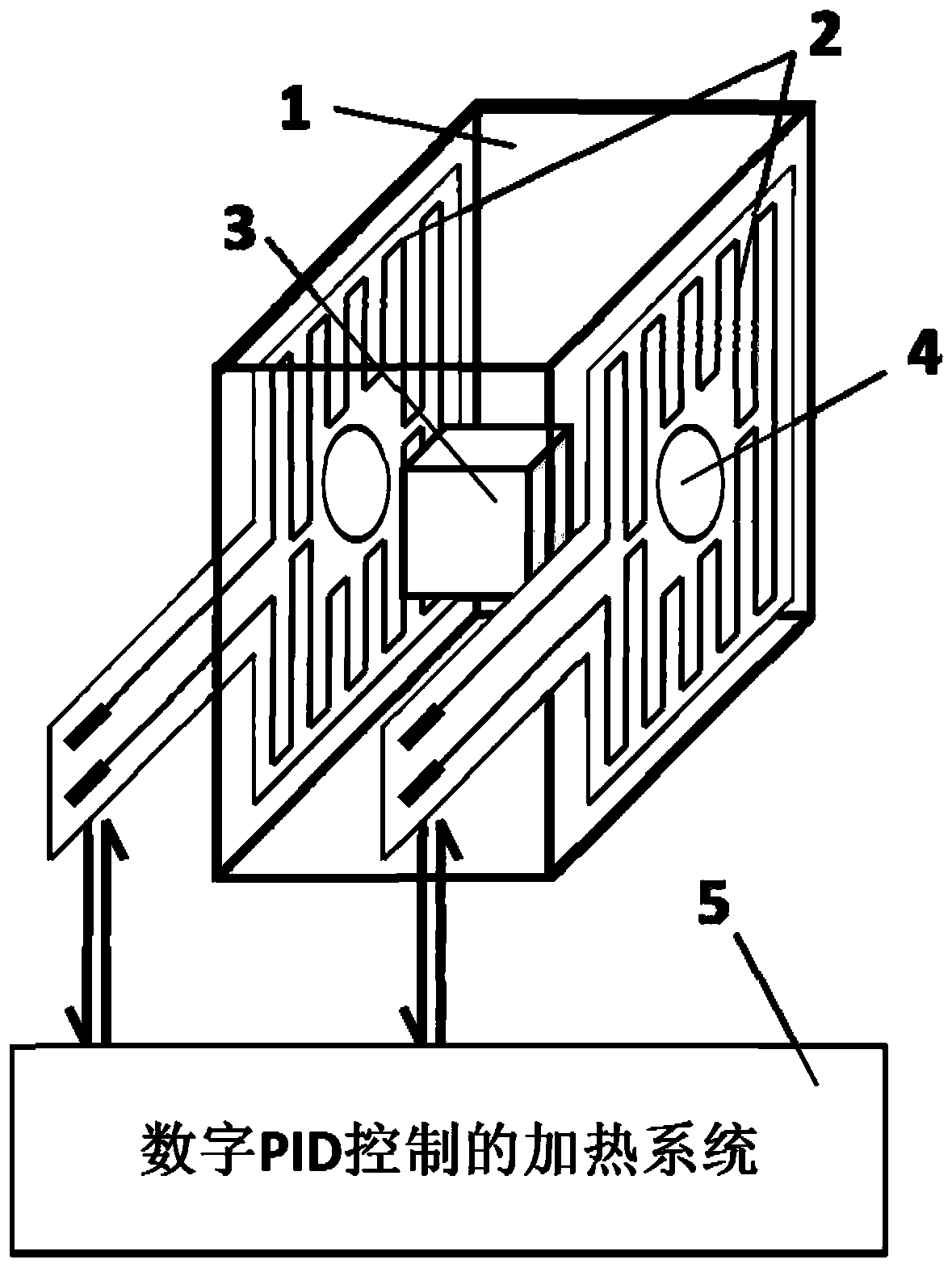

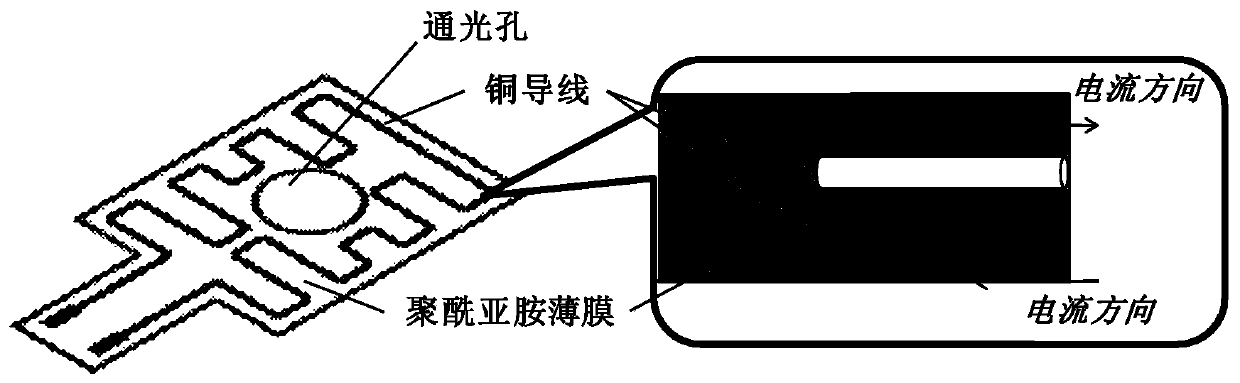

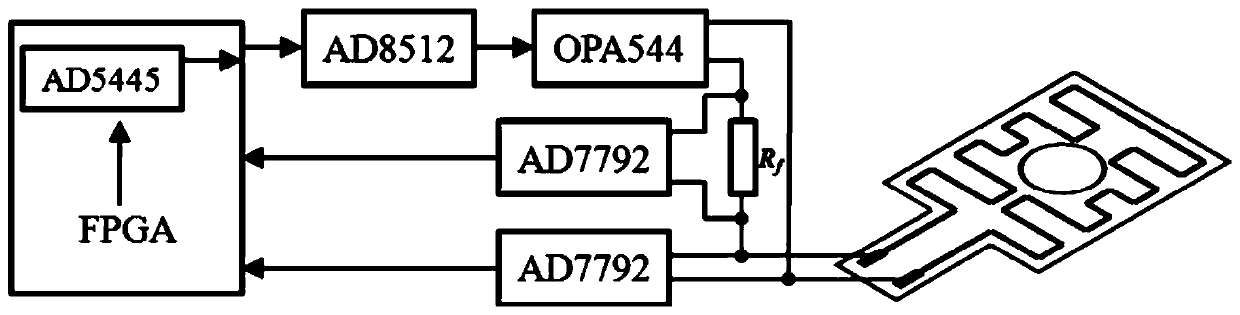

[0030] The non-magnetic heating technology of the atomic gas chamber is the key technology in the SERF gyroscope to ensure the normal operation of the gyroscope. The existing non-magnetic heating technology realizes the PID heating control of the atomic gas chamber by setting a non-magnetic heating chip and a temperature feedback element (such as Pt100). However, the driving current applied when the temperature feedback element is working will still introduce a weak magnetic field and interfere with the output signal of the SERF gyroscope. Moreover, the temperature feedback element placed on the gas chamber heating body can only measure the temperature at a point, which cannot eliminate the temperature gradient existing in the heating process of the atomic gas chamber, which restricts the further improvement of the SERF gyroscope's zero bias stability and other performance. In response to this problem, the present invention proposes a non-magnetic heating and temperature measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com