Method for detecting residual free lithium content in ternary anode material

A detection method and positive electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of inconspicuous color mutation, increased residual free lithium content, and poor accuracy of test results, achieving high precision, enhanced stability, and small error effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

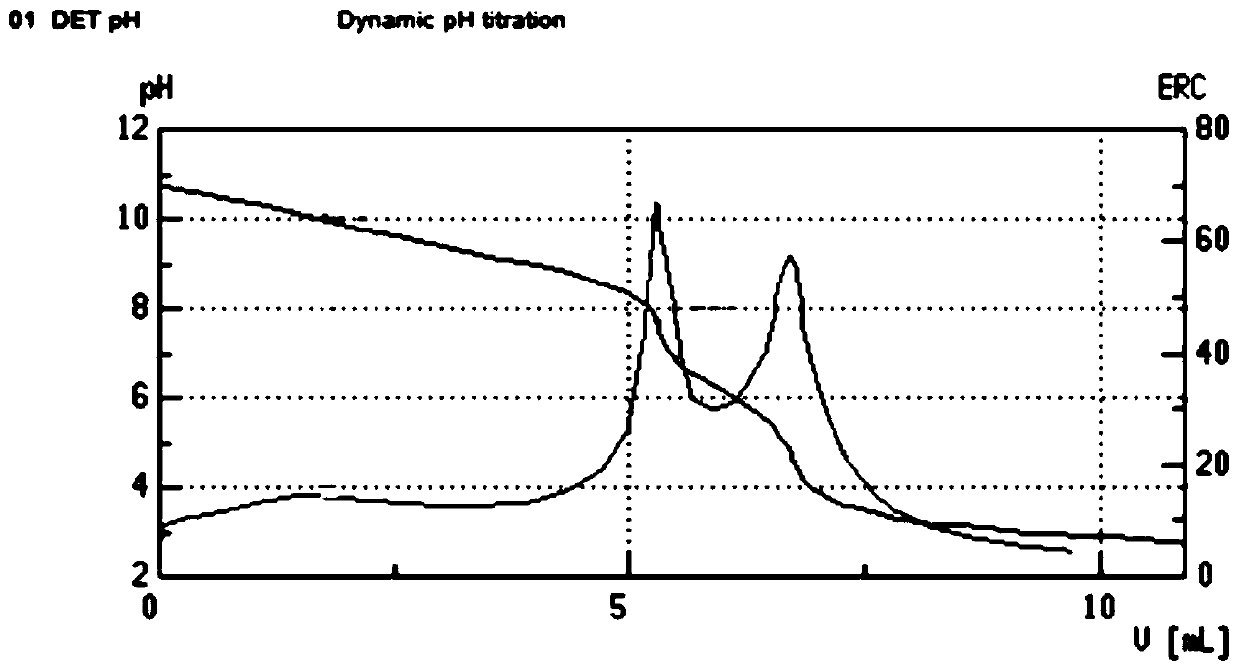

[0022] Example 1 LiNi0.8Co0.8Mn0.1O 2 Detection method of residual free lithium content in

[0023] Take 5g LiNi0.8Co0.8Mn0.1O 2 The sample of ternary positive electrode material is placed in a 100mL conical flask with a stopper, accurately weighed, and the mass of the sample is recorded in m1. The magnetic stirrer is increased in the bottle, and 100g of boiled distilled water is accurately weighed in a conical flask with a stopper, and recorded. The mass of distilled water is m2. Close the Erlenmeyer flask with a non-porous rubber stopper.

[0024] Open the rubber stopper, stuff it into a stoppered Erlenmeyer flask with a self-made gas replacement device, and use nitrogen to replace the gas in the bottle. The purging time is about 10 minutes. After purging, immediately stop the cork with a rubber stopper.

[0025] Place the Erlenmeyer flask with a stopper on a magnetic stirrer at room temperature and stir for 30 minutes, and adjust the rotation speed to the maximum, while ...

Embodiment 2

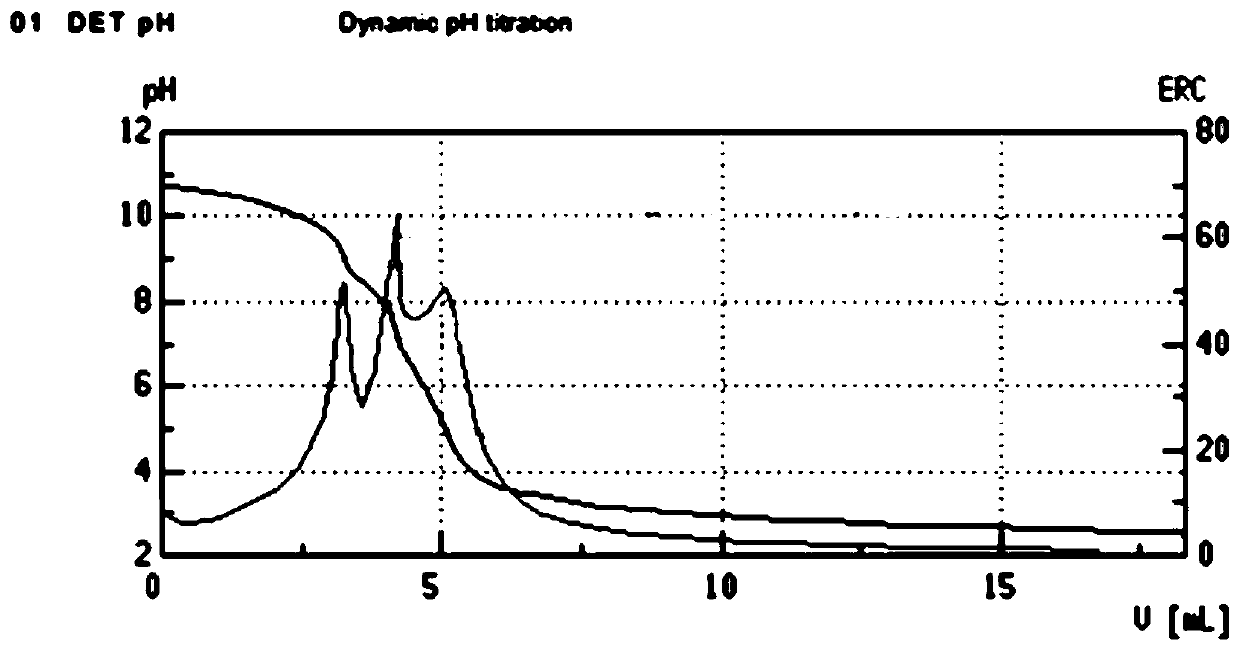

[0032] Example 2 LiNi0.8Co0.1Mn0.1O 2 Detection method of residual free lithium content in

[0033] Take 6gLiNi0.8Co0.8Mn0.1O 2 The sample of ternary positive electrode material is placed in a 100mL conical flask with a stopper, accurately weighed, and the mass of the sample is recorded in m1. The magnetic stirrer is increased in the bottle, and 90g of boiled distilled water is accurately weighed in a conical flask with a stopper, and recorded. The mass of distilled water is m2. Close the Erlenmeyer flask with a non-porous rubber stopper.

[0034] Open the rubber stopper, stuff it into a stoppered Erlenmeyer flask with a self-made gas replacement device, use nitrogen to replace the gas in the bottle, and purge for about 5 minutes. After the purge is completed, immediately plug the bottle with a rubber stopper.

[0035] Place the Erlenmeyer flask with a stopper on a magnetic stirrer at room temperature and stir for 40 minutes, and adjust the rotation speed to the maximum, wh...

Embodiment 3

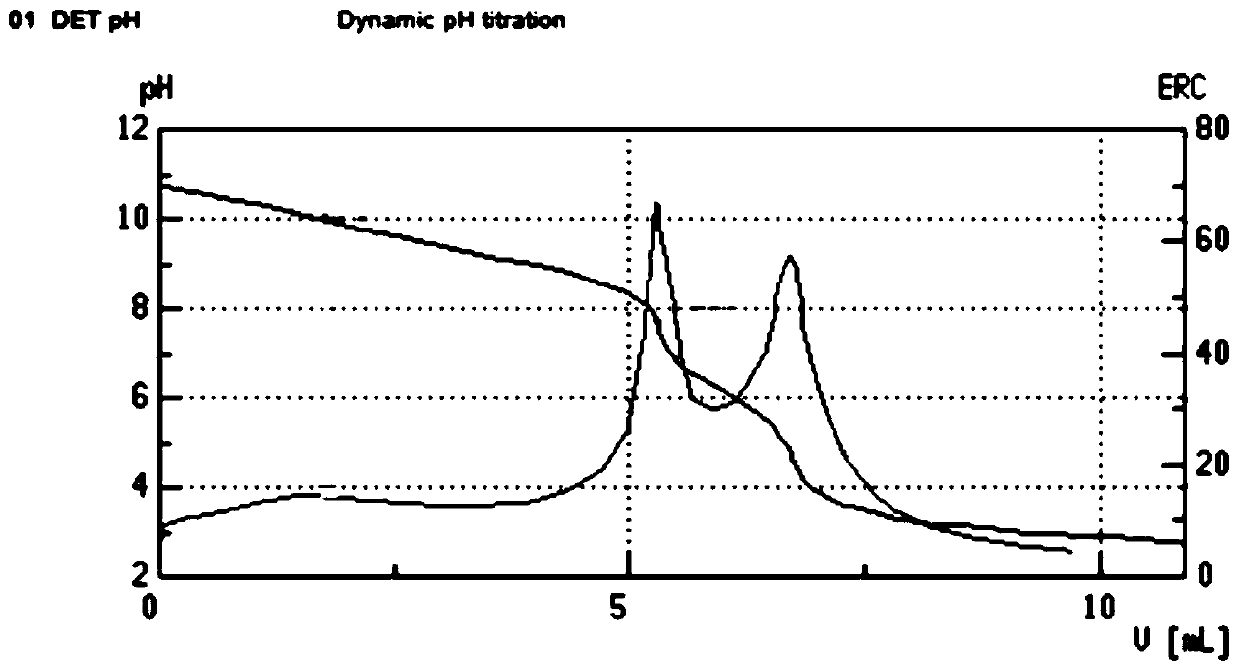

[0042] Example 3 LiNi0.8Co0.1Mn0.1O 2 Detection method of residual free lithium content in

[0043] Take 4gLiNi0.8Co0.8Mn0.1O 2 The sample of ternary positive electrode material is placed in a 100mL conical flask with a stopper, accurately weighed, and the mass of the sample is recorded in m1. The magnetic stirrer is increased in the bottle, and 100g of boiled distilled water is accurately weighed in a conical flask with a stopper, and recorded. The mass of distilled water is m2. Close the Erlenmeyer flask with a non-porous rubber stopper.

[0044] Open the rubber stopper, stuff it into a stoppered Erlenmeyer flask with a self-made gas replacement device, use nitrogen to replace the gas in the bottle, and purge for about 15 minutes. After the purge is completed, immediately plug the bottle with a rubber stopper.

[0045] Place the stoppered Erlenmeyer flask on a magnetic stirrer at room temperature and stir for 10 minutes, and adjust the speed to the maximum, while avoiding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com