Regional design pole piece and battery provided with pole piece

A regionalization and pole piece technology, applied in the direction of secondary battery, battery pack components, secondary battery repair/maintenance, etc., can solve the problem of reducing battery, difficult to reduce battery ion current or electronic current, and internal short circuit Problems such as the partition of the surrounding electrode area can be solved to achieve the effect of improving safety and reducing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A lithium-manganese dioxide battery.

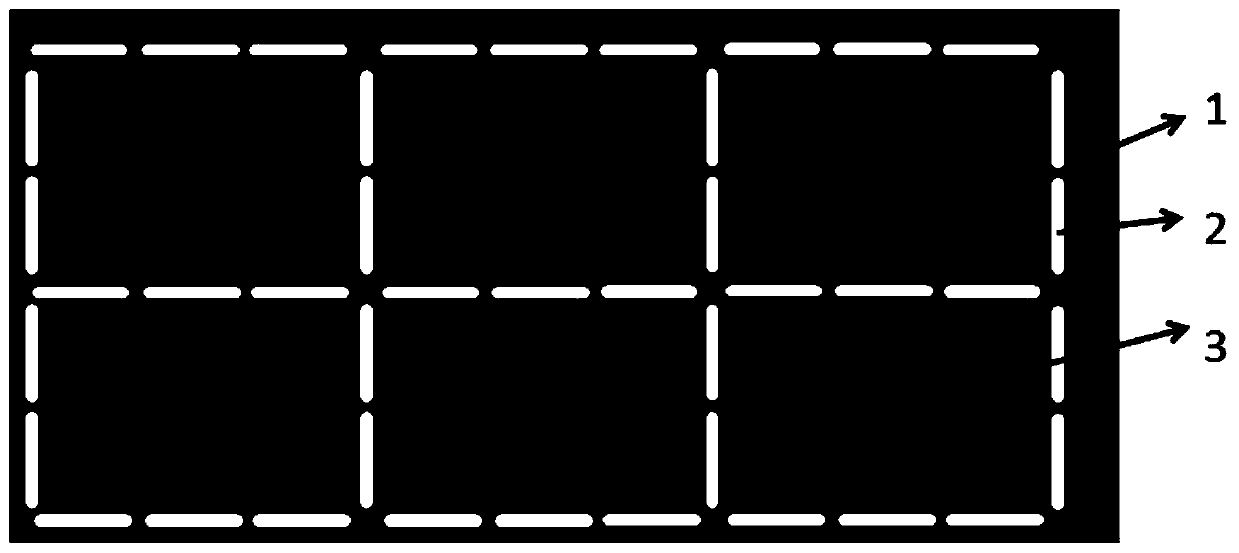

[0056] Such as figure 1 As shown, the negative electrode current collector consists of a perforated conductive plate 1 . The main function of the conductive plate 1 is to conduct electronic current, and the material of the conductive plate 1 can be any one or a combination of metal materials, PTC materials, and conductive polymers. In this embodiment, the conductive plate 1 is a stainless steel foil, on which an oblong hole 2 is punched. The area surrounded by the oblong holes 2 forms the conductive plate area block 3; the distance between the adjacent oblong holes 2 is 0.1 mm to 50 mm, preferably 3 mm, and the uncut holes between the adjacent oblong holes 2 part, it forms the electronic current-limiting part between the adjacent area blocks. In this embodiment, the electronic current limiting part is integrally connected with the area block.

[0057] Such as figure 2 , image 3 ( image 3 is along figure 2 As shown in th...

Embodiment 2

[0065] A lithium-manganese dioxide battery.

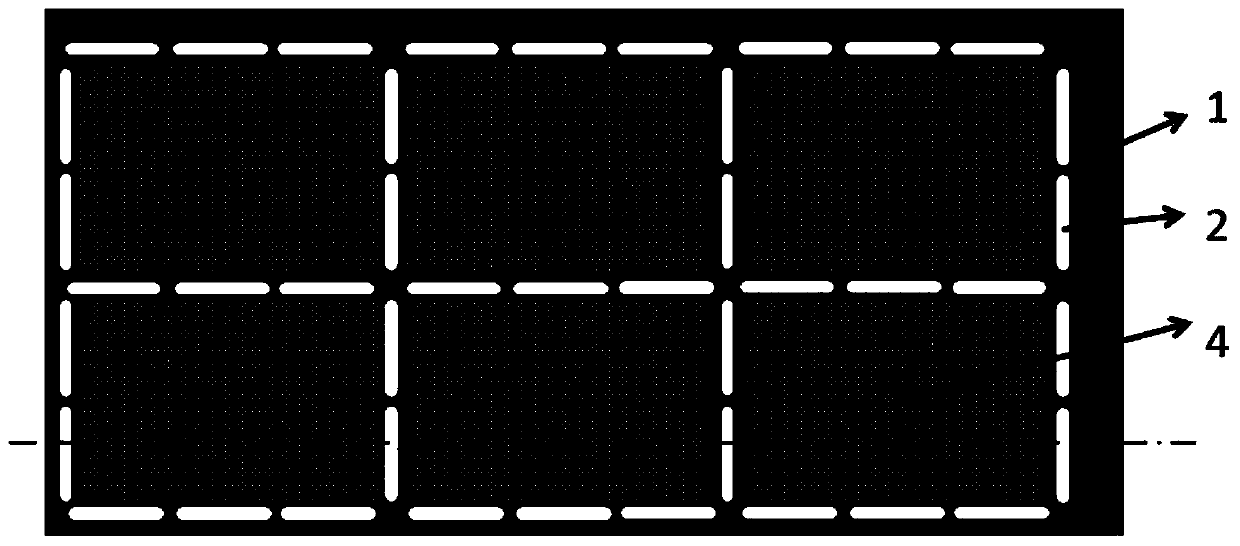

[0066] The battery structure and preparation process are basically the same as in Example 1, the difference is that: Figure 4 , Figure 5 ( Figure 5 is along Figure 4 As shown in the cross-sectional view at the dotted line), a thermal insulation layer 6 and a liquid barrier layer 5 are coated in sequence at the adjacent positions between the conductive plate area blocks 3 (including the electronic current limiting part and slightly expanded). The main function of the heat insulating layer 6 is to insulate heat, slowing down the heat loss of the electronic current limiting part when it is blown; the main function of the liquid barrier layer 5 is to isolate the electrolyte. The components of the heat insulation layer 6 and the liquid barrier layer 5 are both aluminum oxide (Al2O3) + acrylic glue. The aluminum oxide content in the thermal insulation layer 6 is higher than that of the liquid barrier layer 5, and the thermal insu...

Embodiment 3

[0068] A lithium-manganese dioxide battery.

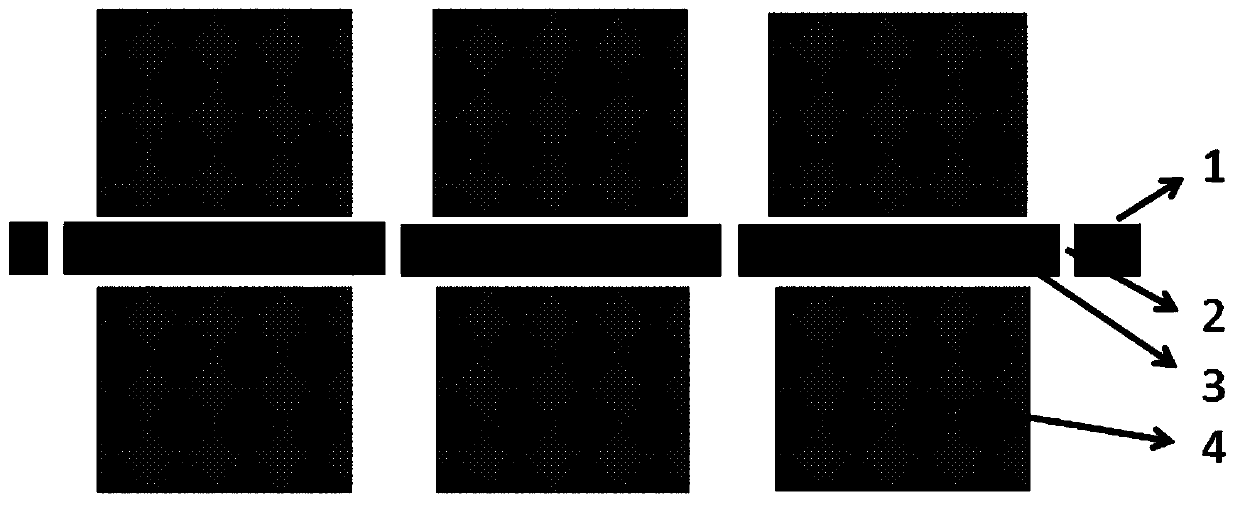

[0069] The battery structure and preparation process are basically the same as in Example 2, the difference is that: Image 6 , Figure 7 ( Figure 7 is along Image 6 As shown in the cross-sectional view at the dotted line), in addition to the oblong hole 2 on the conductive plate 1, there are thinned areas 7, large round holes 8, and small round holes 9 on the conductive plate. The oblong hole 2, the conductive plate thinning area 7, and the large circular hole 8 jointly form the electronic current limiting part between the conductive plate area blocks 3; the small circular hole 9 is conducive to the pressing of the lithium strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com