A kind of hydrogenation treatment catalyst and preparation method thereof

A technology for hydrotreating and catalyst, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problems of waste of active metal, low utilization rate of metal, etc., to improve the activity and avoid the formation of sharp Crystal phase, the effect of reducing the amount of metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

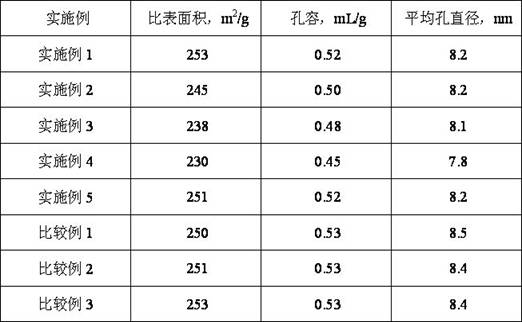

Embodiment 1

[0047] (1) Preparation of Mo-Co-P aqueous solution:

[0048] 3.8g phosphoric acid H 3 PO 4 (Concentration 85 wt%) was dissolved in 80mL of water, then added 10.4g molybdenum trioxide and 4.8g basic cobalt carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Co-P aqueous solution. where MoO 3 The concentration is 0.1g / mL, Co 2 o 3 The concentration of P is 0.025g / mL, and the concentration of P is 0.01g / mL.

[0049] (2) Preparation of catalyst:

[0050] 76.7g alumina support (pore volume 0.70mL / g, specific surface area 300m 2 / g, cylindrical strip shape, diameter 0.8mm) was added to 200mL cyclohexane solution containing 38.5g dodecyltrimethoxysilane, reacted at 50°C for 3.0h, and dried at 70°C for 8h to obtain the pre-catalyst Body A; then added to 200mL5# diesel oil, soaked for 30min and then filtered, and the obtained material was placed in a low-temperature reaction bath at 0°C. Measure 80mL of Mo-Co-P aqueous solution ...

Embodiment 2

[0056] (1) Preparation of Mo-Co-P aqueous solution:

[0057] 5.7g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 15.6g of molybdenum trioxide and 7.2g of basic cobalt carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Co-P aqueous solution. where MoO 3 The concentration is 0.15g / mL, Co 2 o 3 The concentration of P is 0.038g / mL, and the concentration of P is 0.015g / mL.

[0058] (2) Preparation of catalyst:

[0059] 71.5g alumina carrier (pore volume 0.70mL / g, specific surface area 300m 2 / g, cylindrical strip shape, diameter 0.8mm) was added to 200mL cyclohexane solution containing 33.6g hexadecyltrimethoxysilane, reacted at 50°C for 3.0h, dried at 70°C for 8h, and obtained the pre-catalyst Body A; then added to 200mL0# diesel oil, soaked for 30min and then filtered, and the obtained material was placed in a low-temperature reaction bath at -10°C. Measure 75mL of Mo-Co-P aqueo...

Embodiment 3

[0065] (1) Preparation of Mo-Co-P aqueous solution:

[0066] 7.6g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 20.8g of molybdenum trioxide and 9.6g of basic cobalt carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Co-P aqueous solution. where MoO 3 The concentration is 0.2g / mL, Co 2 o 3 The concentration of P is 0.05g / mL, and the concentration of P is 0.02g / mL.

[0067] (2) Preparation of catalyst:

[0068] 66.9g alumina support (pore volume 0.70mL / g, specific surface area 300m 2 / g, cylindrical strip shape, diameter 0.8mm) was added to 200mL cyclohexane solution containing 19.0g hexadecyltrimethoxysilane, reacted at 50°C for 3.0h, dried at 70°C for 8h, and obtained the pre-catalyst Body A; then added to 200mL0# diesel oil, soaked for 30min and then filtered, and the obtained material was placed in a low-temperature reaction bath at -10°C. Measure 50mL of Mo-Co-P aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com