Hydrogenation catalyst regenerating method

A hydrogenation catalyst and catalyst technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

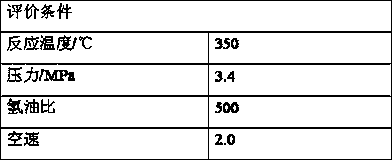

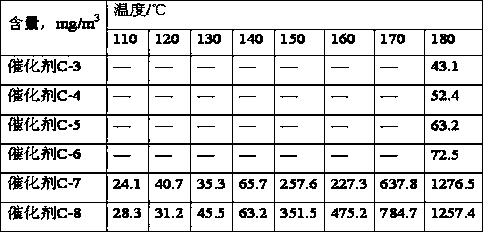

Embodiment 1

[0024] Take a deactivated hydrotreating catalyst with a carbon deposit of 5.8%, and its active metal components are Mo and Ni, and perform carbon burning regeneration treatment in an oxygen-containing atmosphere. At a heating rate of 3°C / min, the temperature was raised to 200°C, kept at a constant temperature for 10 hours, and then continued to rise to 310°C, kept at a constant temperature for 8 hours. The obtained sample had a carbon content of 1.8% and a sulfur content of 2.0%. The obtained sample was named C-1.

[0025] Take a deactivated hydrotreating catalyst with a carbon deposition of 7.9%, and its active metal components are Mo, Ni, Co, and use different conditions to burn carbon regeneration treatment in an oxygen-containing atmosphere. At a heating rate of 3°C / min, the temperature was raised to 200°C and kept at a constant temperature for 10 hours, and then continued to rise to 320°C and kept at a constant temperature for 10 hours. The obtained sample had a carbon con...

Embodiment 2

[0027] Take 15g of tetrakis hydroxymethylphosphorus sulfate aqueous solution (solution concentration: 75wt%), spray catalyst C-1, after aging for 3 hours, treat at 100°C for 3 hours, take 2.3ml of hydrazine hydrate, spray it, and spray it at 100°C Low temperature heat treatment for 3 hours. That is, the desired catalyst C-3 is obtained.

Embodiment 3

[0029]Take 14g of tetrahydroxyethylphosphorus sulfate, dilute it with water to form a 75ml solution, spray the catalyst C-2 with the solution, and after aging for 3 hours, heat-treat at 80°C for 3 hours. After spraying with 2.3ml of hydrazine hydrate, heat treatment at a low temperature of 100°C for 3 hours. That is, the desired catalyst C-4 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com