Energy-saving glass for building and preparation method of energy-saving glass

An energy-saving glass and architectural technology, applied in the field of glass preparation, can solve problems such as being easily attached by dust, affecting indoor lighting, affecting the appearance of windows and curtain walls, etc., to achieve the effect of increasing sound insulation and heat insulation performance, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

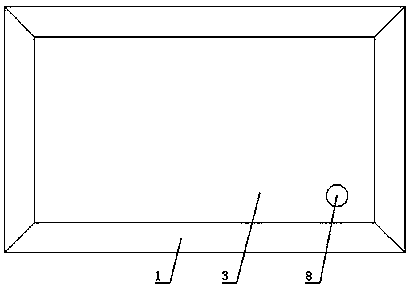

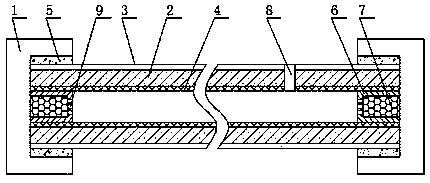

[0028] Such as figure 1 and figure 2 As shown, the present invention is an energy-saving glass used in buildings, including a frame 1, and the interior of the frame 1 is provided with a tempered glass 2, the number of the tempered glass 2 is two, and the front of one of the tempered glass 2 is provided with an air extraction hole 8, The sides of the two toughened glasses 2 that are far away from each other are coated with a dust-proof film 3, and the space between the dust-proof film 3 and the frame 1 is coated with glass glue 5, and the sides of the two toughened glasses 2 that are close to each other are coated with an explosion-proof film 4, A spacer 6 is arranged between the two toughened glasses 2, and the number of the spacer 6 is two. The adjacent side of the two spacers 6 is provided with an air suction hole 9, and a getter 7 is stored inside the spacer 6.

[0029] Wherein, the frame 1 can be made of aluminum alloy.

[0030] Wherein, the parts by weight of the tempe...

Embodiment 2

[0045] The difference between this embodiment 2 and embodiment 1 is:

[0046] Wherein, the frame 1 can be made of plastic steel.

[0047]Wherein, the parts by weight of the tempered glass 2 composition are: 7 parts of quartz sand, 6 parts of soda ash, 13 parts of limestone, 9 parts of barium carbonate, 6 parts of aluminum powder, and 18 parts of feldspar.

[0048] Among them, the parts by weight of the dust-proof film 3 components are: 7 parts of high-density polyvinyl chloride, 10 parts of medium-density polyvinyl chloride, 8 parts of low-density polyvinyl chloride, 45 parts of mica, 25 parts of alkyl sulfate, stearin acid 6 parts.

[0049] Wherein, the parts by weight of the composition of explosion-proof film 4 are: 22 parts of polyurethane, 1 part of acrylic adhesive, 7 parts of ultraviolet stabilizer, 1 part of lithium hydroxide, and 0.3 part of antioxidant.

[0050] Among them, the following steps are included:

[0051] S1: Preparation of frame 1

[0052] S2: prepara...

Embodiment 3

[0063] The difference between this embodiment 3 and embodiment 1 is:

[0064] Wherein, the frame 1 can be made of PVB resin.

[0065] Wherein, the parts by weight of the tempered glass 2 composition are: 8 parts of quartz sand, 10 parts of soda ash, 14 parts of limestone, 10 parts of barium carbonate, 7 parts of aluminum powder, and 20 parts of feldspar.

[0066] Among them, the parts by weight of the dust-proof film 3 components are: 8 parts of high-density polyvinyl chloride, 40 parts of medium-density polyvinyl chloride, 10 parts of low-density polyvinyl chloride, 50 parts of mica, 30 parts of alkyl sulfate, stearin 8 parts acid.

[0067] Among them, the parts by weight of the explosion-proof film 4 are: 26 parts of polyurethane, 2 parts of acrylic adhesive, 8 parts of ultraviolet stabilizer, 2 parts of lithium hydroxide, and 0.5 part of antioxidant.

[0068] Among them, the following steps are included:

[0069] S1: Preparation of frame 1

[0070] S2: preparation of te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com