Laser quenching machine for gear

A laser quenching and gear technology, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of affecting quenching efficiency, affecting the quality of gears, and troublesome quenching operations, so as to ensure work efficiency, uniform and reliable cooling, and firm and reliable installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

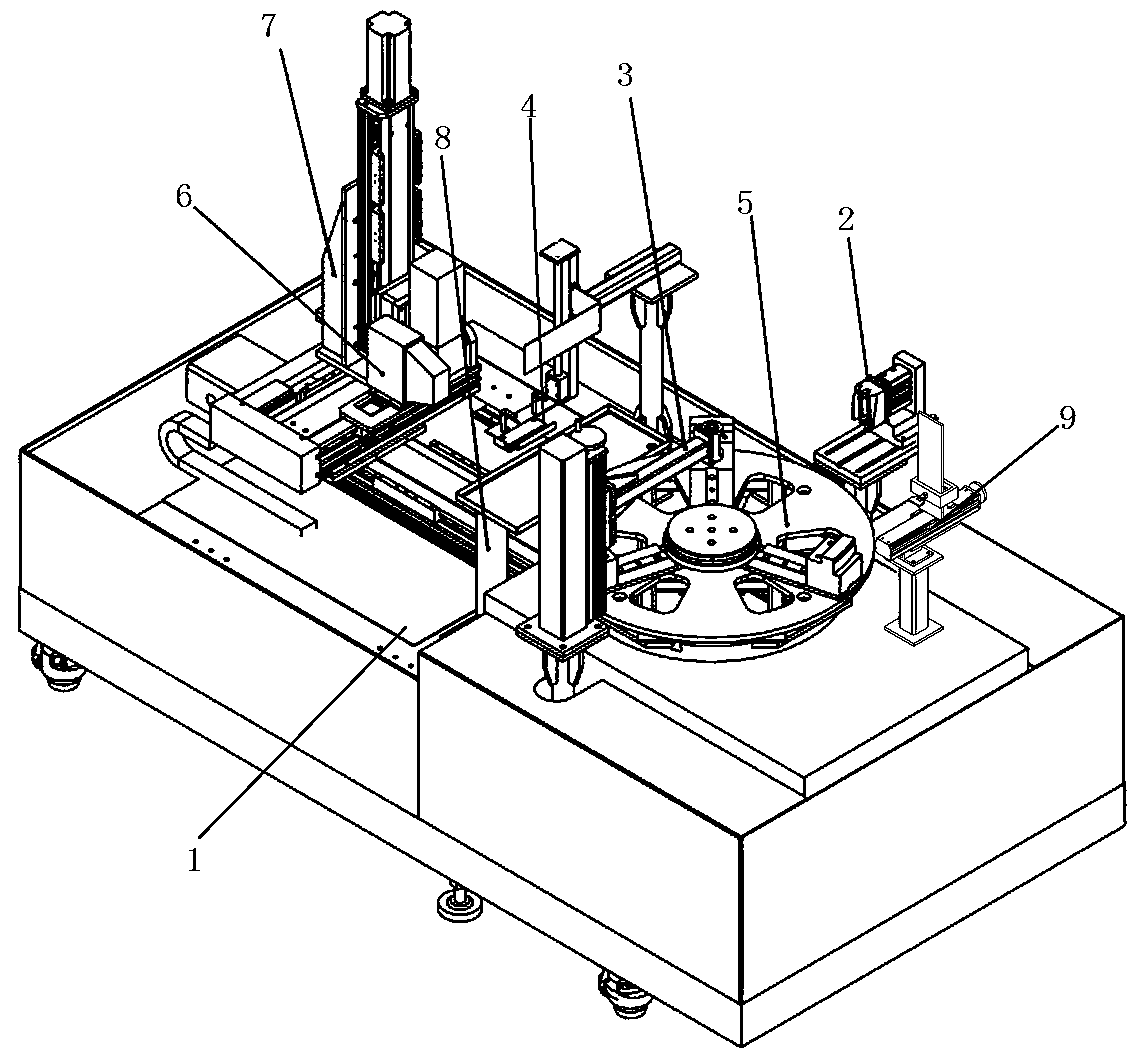

[0056] Such as figure 1 As shown, a gear laser quenching machine includes a quenching platform 1, a gear installation turntable 5 installed on the quenching platform 1, a laser head 6, a gear positioning mechanism 2, a top mechanism 3, a laser head moving device 7, a cooling mechanism 4, Coolant recovery mechanism 8 and cleaning mechanism 9;

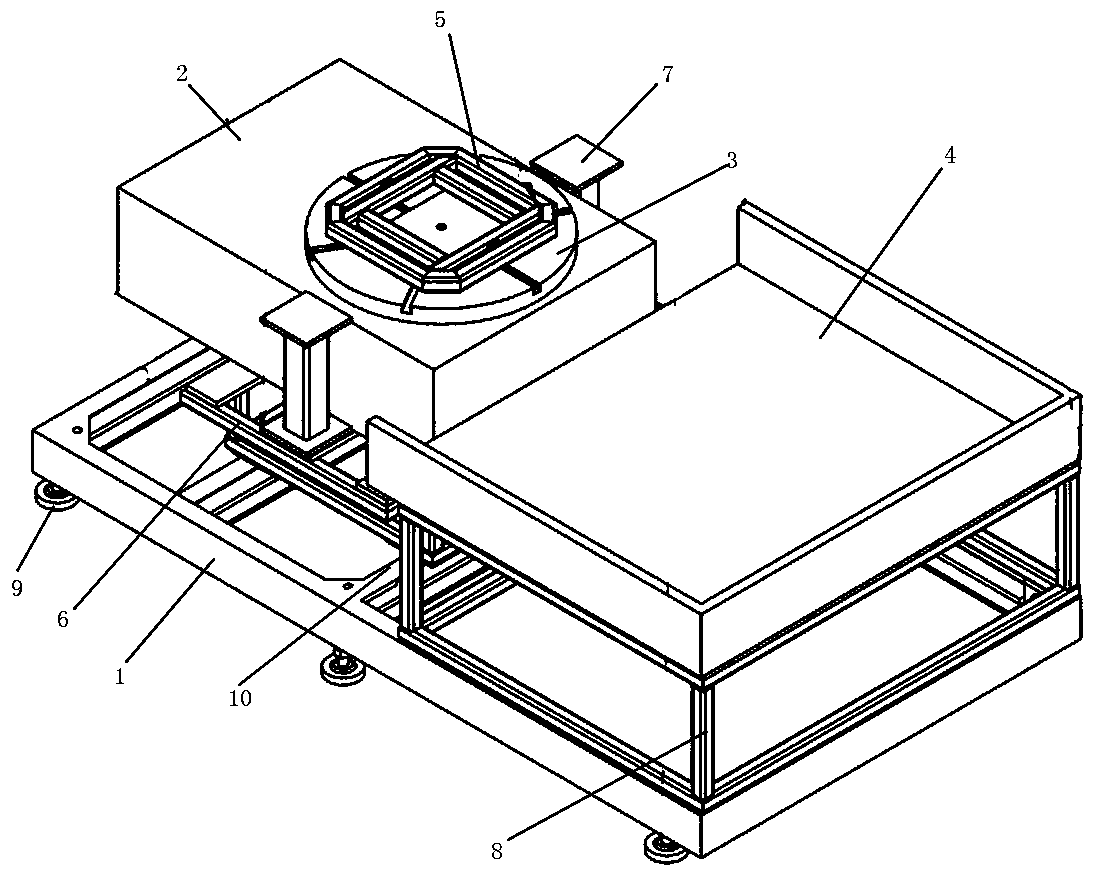

[0057] Such as figure 2 As shown, the quenching platform includes a base 1, a four-axis rotary table 2 installed on the base for installing a gear installation turntable, and a laser head installation table 4 for installing a laser head. The height of the laser head installation table 4 is the same as that of the four-axis rotation The height of table 2 is matched, and the four-axis rotary table 2 is provided with a turntable mounting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com