Multi-layer solid wood compound heated floor capable of being laid fast and processing technology thereof

A technology of solid wood composite and geothermal flooring, which is applied in floors, buildings, building structures, etc., can solve problems such as poor stability, and achieve the effects of excellent wear resistance, strong impact resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

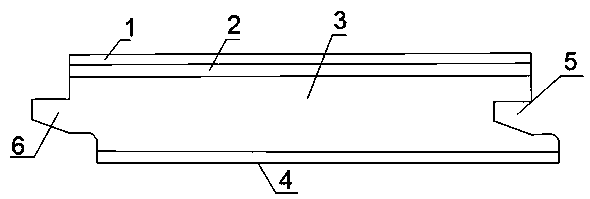

[0028] Multi-layer solid wood composite geothermal floor that can be quickly installed, including a wear-resistant layer and a decorative layer 1, a bottom layer 2, a base material layer 3 and a balance layer 4, the wear-resistant layer and a decorative layer 1, a bottom layer 2, a base material Layer 3 and balance layer 4 are connected in turn,

[0029] The two sides of the multi-layer solid wood composite geothermal floor are respectively provided with a female groove 5 and a tongue 6,

[0030] The horizontal width of the female groove 5 is greater than the length of the tongue 6,

[0031] The vertical thickness of the female groove 5 is greater than the thickness of the tongue 6,

[0032] The female groove 5 and the tongue 6 are completed by the design and milling of the forming knife during the grooving process of the multi-layer solid wood composite geothermal floor. Through the button-shaped design, it can increase the yield rate of the product while fully The quality of the pr...

Embodiment 2

[0034] On the basis of Example 1, the substrate layer 3 is a full eucalyptus multilayer board, the thickness of the substrate layer 3 is 14.8mm, and the full eucalyptus multilayer board is used for good dimensional stability when the environment temperature and humidity changes. , It is not easy to deform, and it is easy to carry out surface decoration treatment.

Embodiment 3

[0036] On the basis of Example 2, the density of the full eucalyptus multi-layer board is: ≥0.68g / cm 3 Therefore, the surface strength of the multilayer solid wood composite geothermal floor can be greatly increased, the impact resistance is strong, and the load-bearing capacity is also good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com