Gas burner for conversion furnace

A gas burner and reformer technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of reducing the flame peak temperature, failing to meet emission standards, and effectively reducing NOx emissions, etc., to achieve uniform flow, The effect of reducing the peak flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

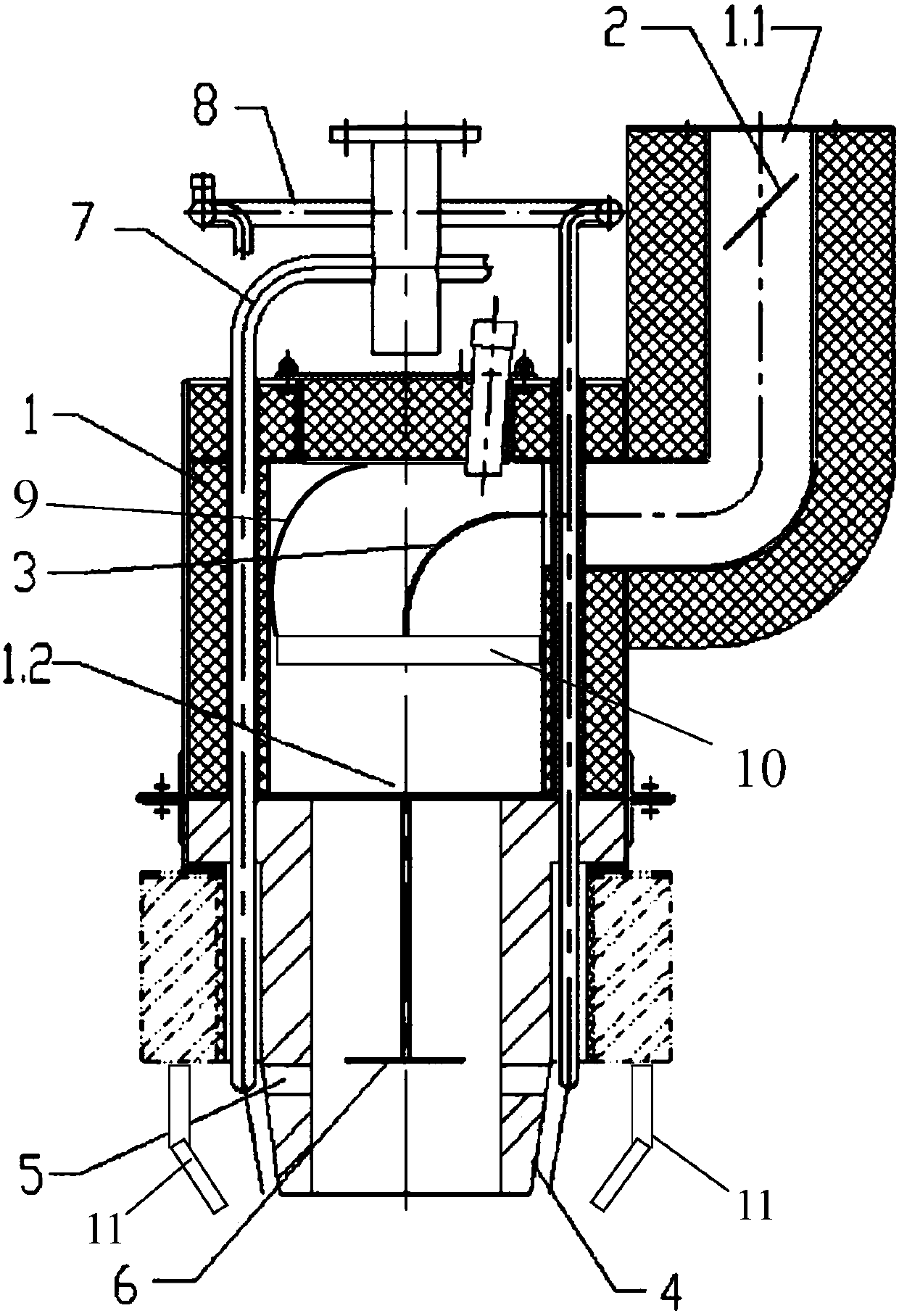

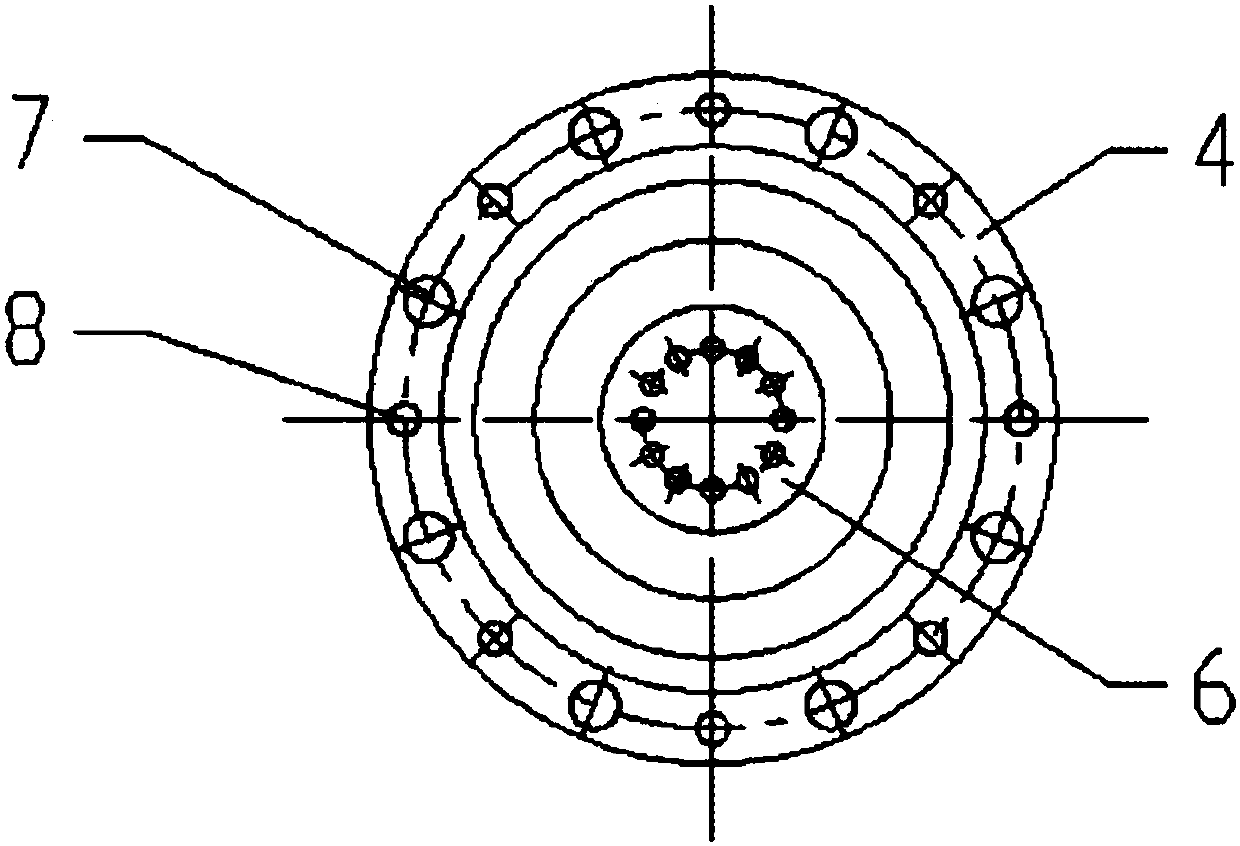

[0018] see Figure 1-2 , a gas burner for a reformer, including a housing 1, the upper part of the housing 1 is provided with an air inlet 1.1, the burner also includes a low-pressure fuel air gun 7 and a high-pressure fuel air gun 8, a low-pressure fuel air gun 7 and a high-pressure fuel air gun 8 passes through the shell 1 and is evenly distributed on the outside of the refractory brick 4 in a staggered manner; it is characterized in that: the first air deflector 3 and the second air deflector 9 with an arcuate surface are arranged in the shell 1, so The first air deflector 3 is arranged at the air inlet of the casing 1, and the second air deflector 9 is arranged on the inner wall opposite to the air inlet of the casing 1; the first air deflector 3 and The second air deflector 9 is used to guide the wind entering the air inlet downward; a number of splitter vanes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com