Total reflection method-based actual contact area measuring instrument

A contact area and total reflection method, applied in the field of mechanical applications, can solve the problems of inability to observe the dynamic changes of the actual contact area, high requirements for ambient light, and high requirements for the production of test pieces, achieving simple structure, high measurement accuracy, and easy capture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

[0035] The invention solves two main technical problems: first, when the experimental material is subjected to a pressure load, the actual contact area can be directly observed and measured by the instrument. Second, under the action of dynamic pressure, the experimental material can use this instrument to observe the evolution of the actual contact area in real time.

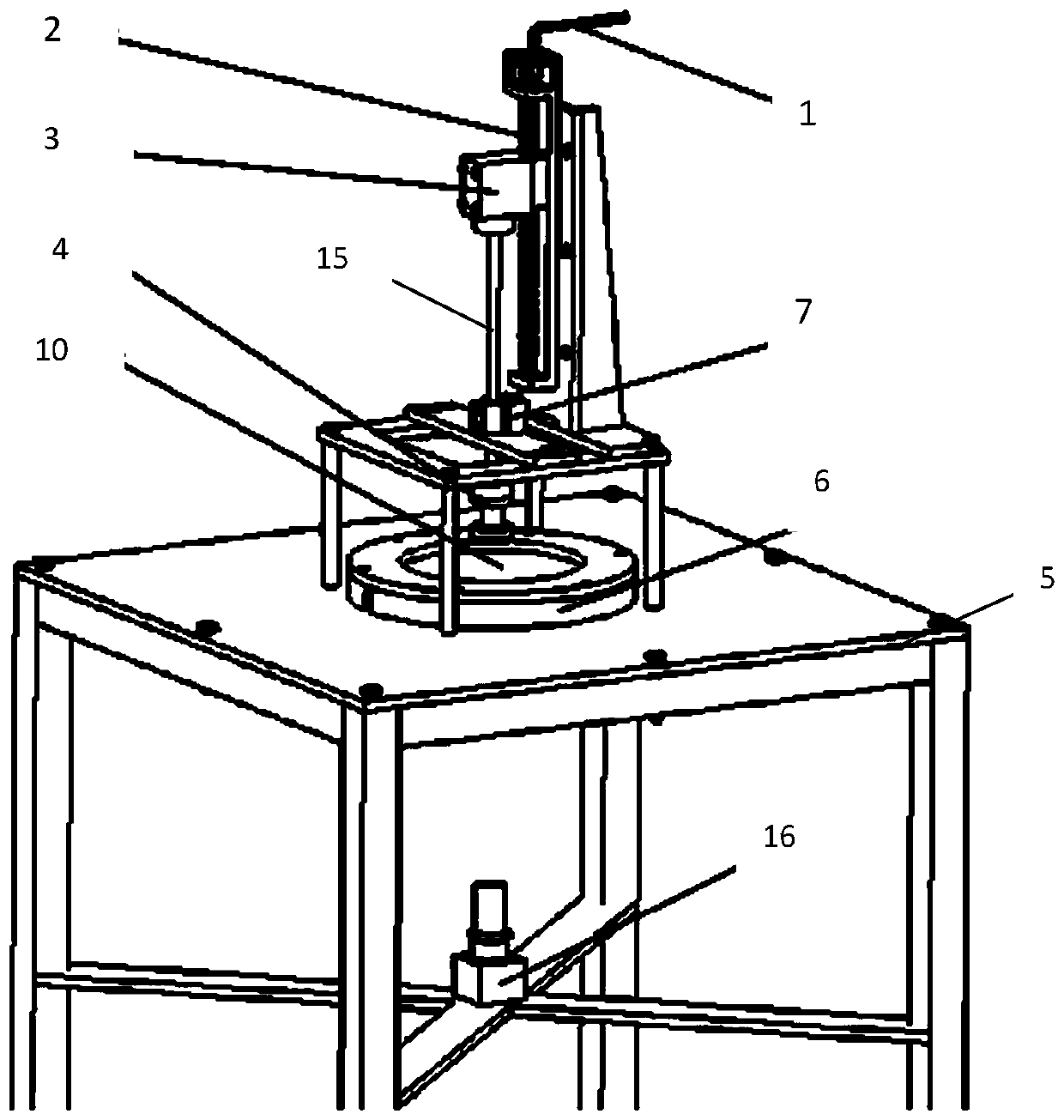

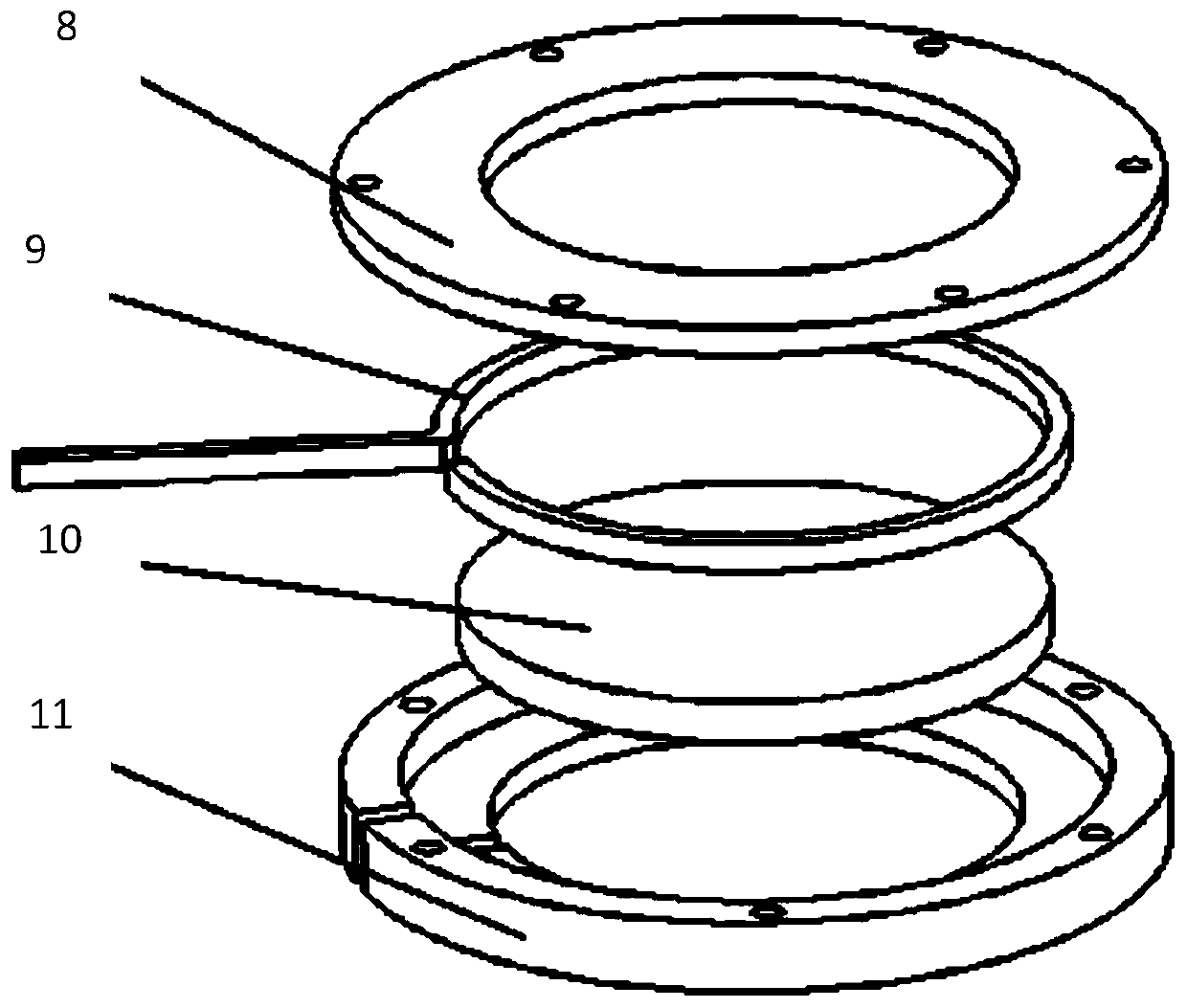

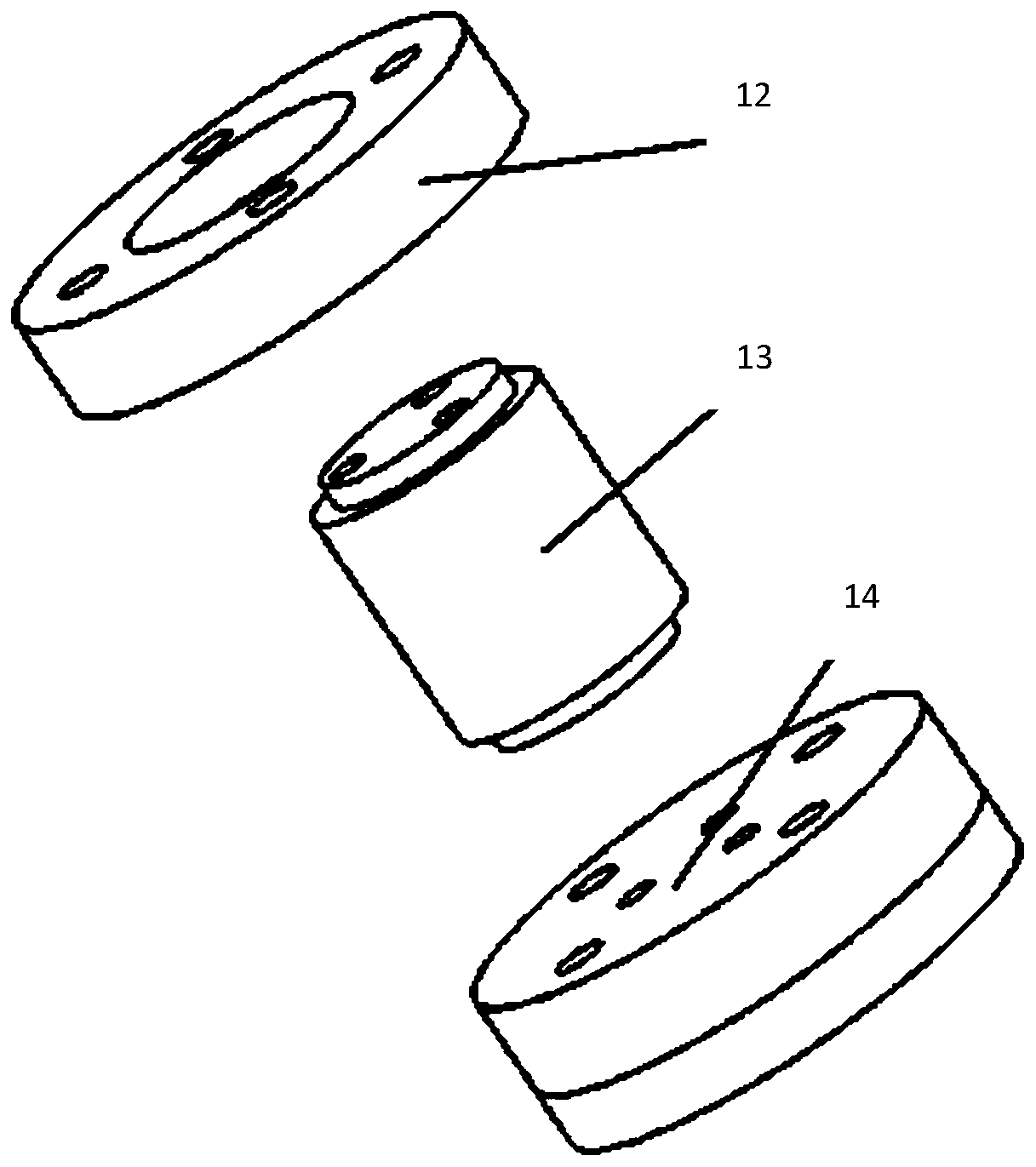

[0036] see figure 1 , the present invention includes a total reflection contact disk 6 for placing experimental materials, the total reflection contact disk 6 is placed on the platform 5, and a loading device for applying a pressure load to the experimental materials is also provided on the platform 5, and the loading device includes a The support on the platform 5 is provided with a lead screw structure, the lead screw structure includes a vertically arranged lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com